Radial azimuth stepless adjustment for gas drilling manifold

A gas drilling and azimuth technology, which is used in liquid/gas jet drilling, earthwork drilling, wellbore flushing, etc. It can solve the problems of arbitrarily adjusting the angle and direction of the pipeline, work intensity and operation time, and reduce installation operations. Time, shorten the installation cycle, avoid the effect of installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

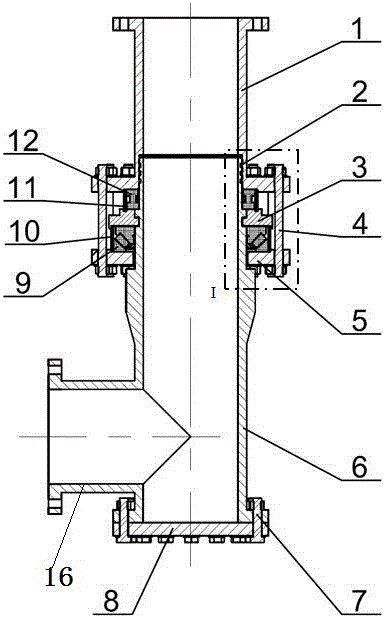

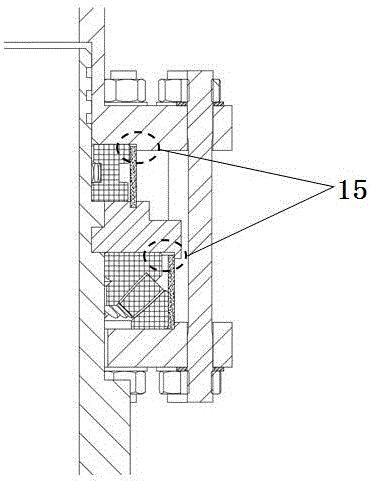

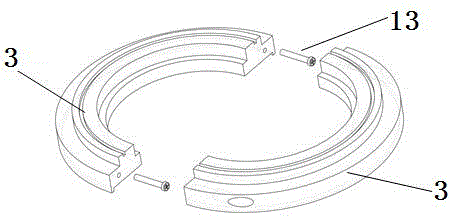

[0035] A radial azimuth stepless angle adjustment mechanism for a gas drilling manifold, including a fixed nipple 1, a clamping piece, a screw set 4, a suspension flange 5, and a rotating nipple 6, and the upper end of the rotating nipple 6 is connected to the fixed nipple 1 is plugged and sealed, and the lower end is provided with a prefabricated fixed-angle outlet connection end 16. The suspension flange 5 is set on the swivel joint 6, and the clamping part is located between the lower end surface of the fixed joint 1 and the suspension flange 5. The rotating short joint 6 is suspended on the clamping part, and the lower end of the hanging flange 5 and the fixed short joint 1 is fixedly connected through the screw kit 4. The annular space between the clamping part and the hanging flange 5 is provided with a roller bearing, and the clamping A roller bearing is arranged between the part and the lower end surface of the fixed pup joint 1.

[0036] In this embodiment, the clampi...

Embodiment 2

[0049] This embodiment further illustrates the present invention in conjunction with the accompanying drawings. The invention can be used in gas drilling techniques such as dry gas drilling (air, nitrogen), atomization drilling, foam drilling and aeration drilling, and manifold systems in other fields.

[0050] The present invention includes fixed short joint 1, "O" type sealing ring 2, semicircle clamp 3, long screw kit 4, suspension flange 5, rotating short joint 6, flange bolt kit 7, blind plate 8, thrust self-aligning roller Bearing 9, dustproof nylon ring a10, dustproof nylon ring b11, thrust cylindrical roller bearing 12. The long screw kit 4 includes a screw, a nut, and a spring washer. Flange bolt kits include bolts, nuts, spring washers.

[0051] The fixed nipple 1 is fixed on the upstream sand discharge pipeline. The rotating sub-joint 6 and the fixed sub-joint 1 belong to the plug-in relationship, and the two realize radial sealing through three "O"-shaped sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com