Inverted arch steel end die and construction method thereof

A construction method and end formwork technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems that the thickness of the protective layer cannot be controlled according to the design requirements, and achieve good results and reduce installation costs. Stitching seams, the effect of not wasting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

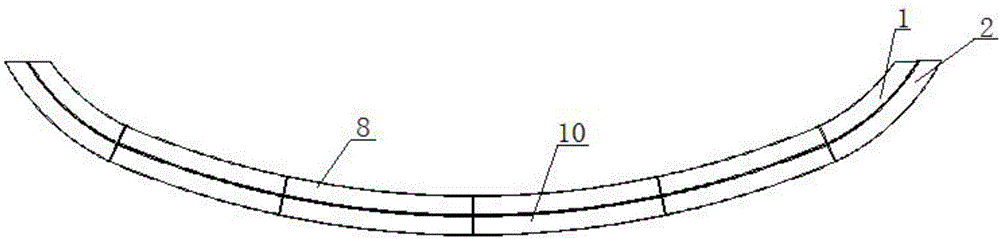

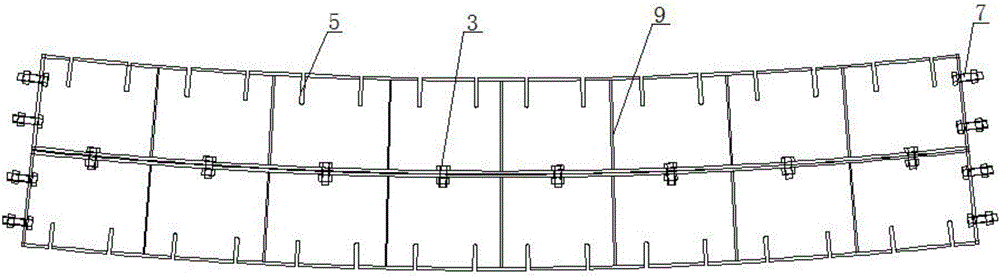

[0026] see Figure 1-Figure 3 , an inverted arch steel end form, comprising an upper steel end form 1 and a lower steel end form 2 of an arc structure; the lower end of the upper steel end form 1 and the upper end of the lower steel end form 2 are linked by vertical bolts 3 , so that the upper steel end die 1 and the lower steel end die 2 are linked into a whole. And one end of the circumferential steel edge waterstop 4 of the inverted arch is clamped between the upper steel end formwork 1 and the lower steel end formwork 2, that is, the upper steel end formwork 1 and the lower steel end formwork 2 connect the circumferential steel edge of the inverted arch The waterstop 4 is clamped; usually half of it goes deep into the inverted arch concrete end of the construction, and half is clamped and fixed by the upper steel end mold 1 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com