Spindle seal pressure steel pipe side water supply pipeline of water turbine unit

A technology of spindle sealing and pressure steel pipes, which is applied in hydropower, machines/engines, mechanical equipment, etc., can solve problems such as large vibration of water supply pipelines, inconsistent design pressure, and failure to decompress normally, so as to ensure safe and stable operation and eliminate Existing defects, effect of eliminating sediment clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

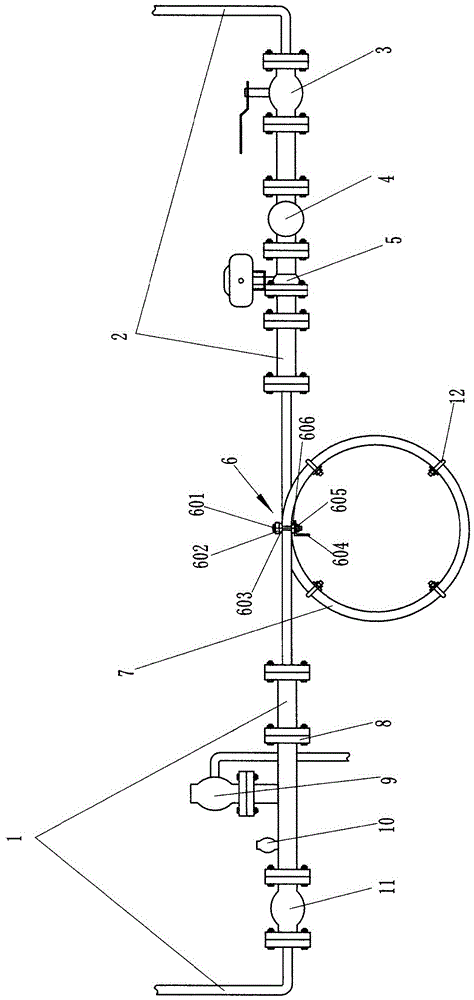

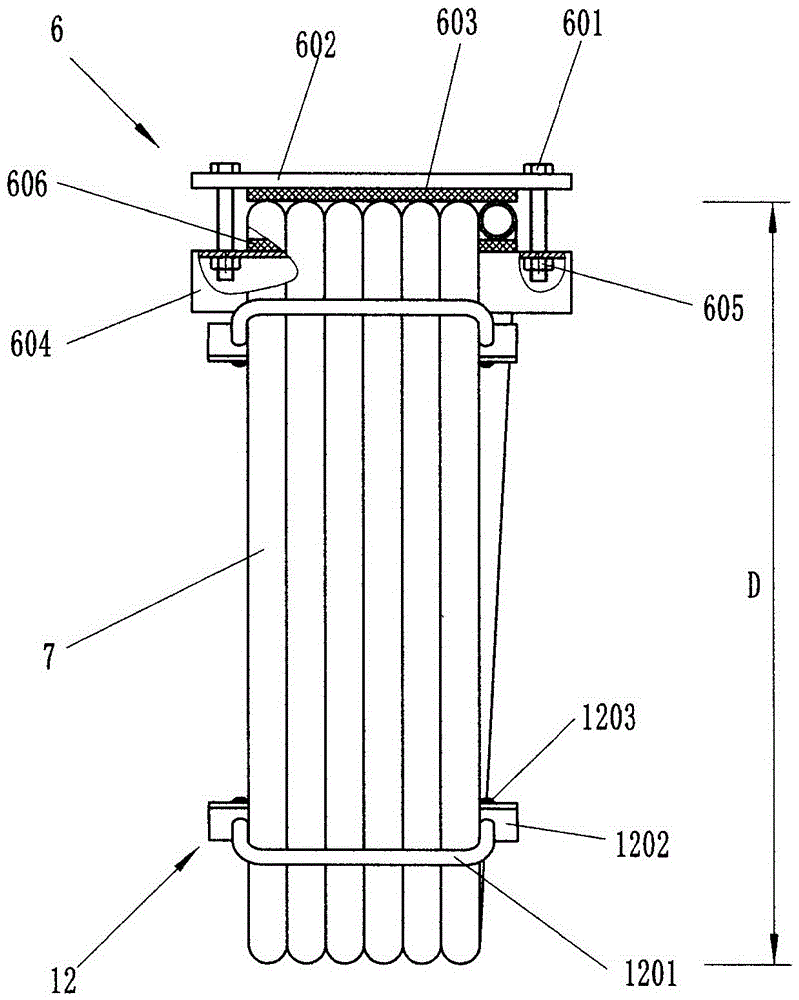

[0013] Such as figure 1 , figure 2 As shown, the main shaft sealing pressure steel pipe side water supply pipeline of the hydraulic turbine unit of the present invention has a left side water supply pipe 1, a right side water supply pipe 2, an electric valve 5, a water intake main valve 3 are installed on the right side water supply pipe 2, and a left side water supply pipe An intermediate flange 8 , a pressure relief valve 9 , a safety valve 10 and a connecting valve 11 are installed on the pipe 1 . The left water supply pipe 1 and the right water supply pipe 2 are connected with a decompression ring pipe 7 through a flange, that is, the water inlet and the water outlet of the decompression ring pipe 7 are respectively connected to the right water supply pipe 2 and the right water supply pipe 2 through a flange. Left water supply pipe 1. The decompression ring pipe 7 is limited by several positioning cards 12 that prevent it from extending outward (extending along the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com