A fully meshed spiral tooth with gradient wall thickness

A scroll, full meshing technology, used in rotary piston pumps, rotary piston machines, components of pumping devices for elastic fluids, etc. , to achieve the effect of improving the area utilization rate, increasing the suction volume, and increasing the intake air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

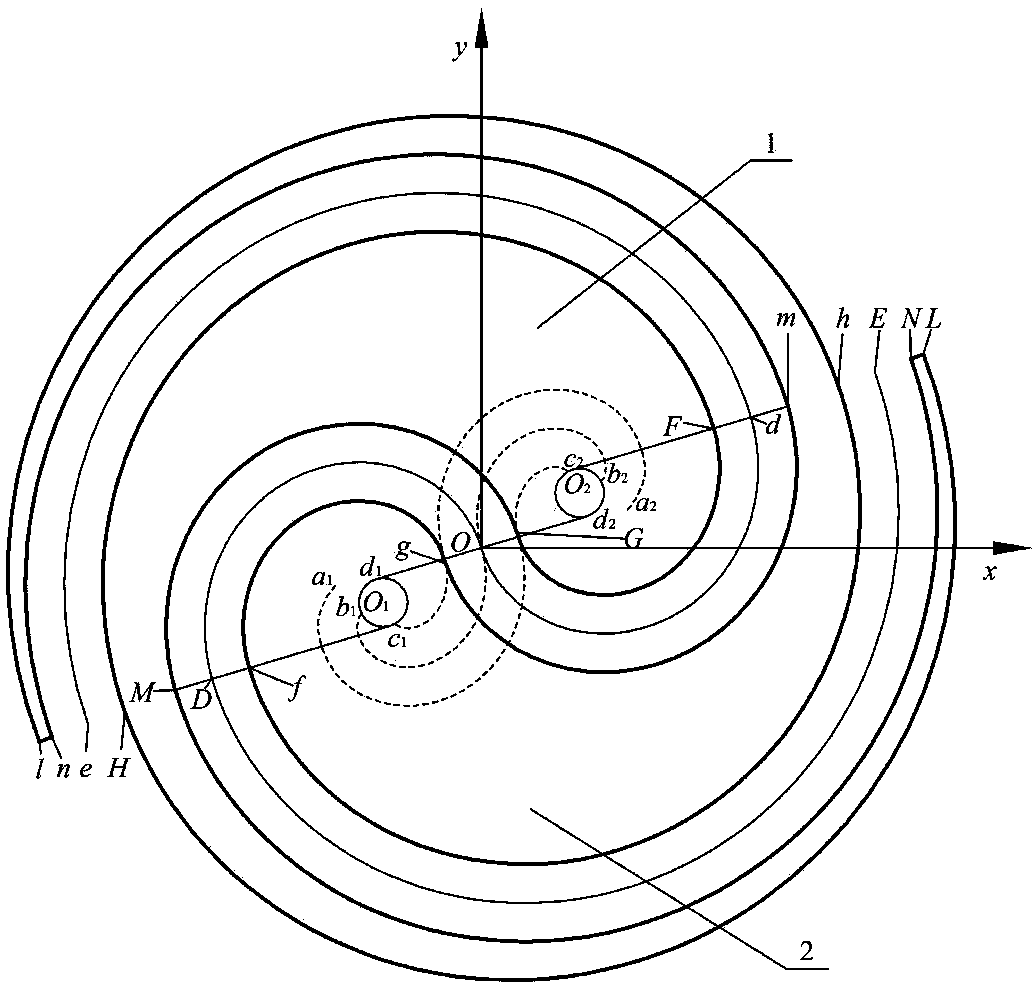

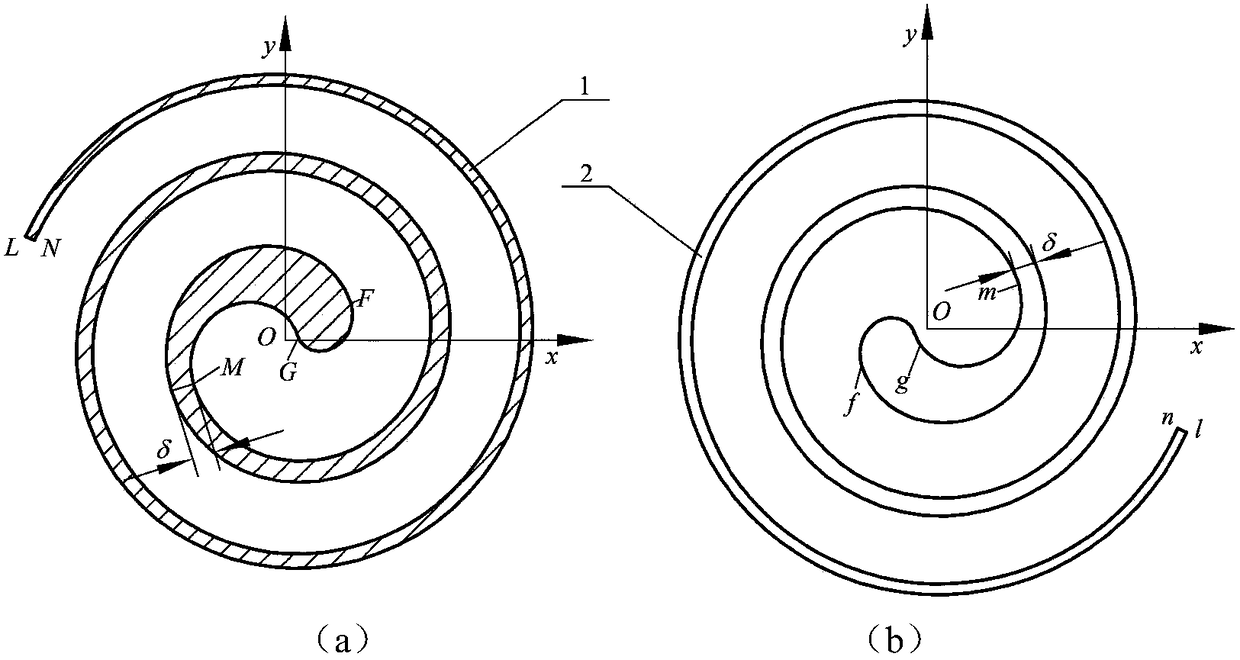

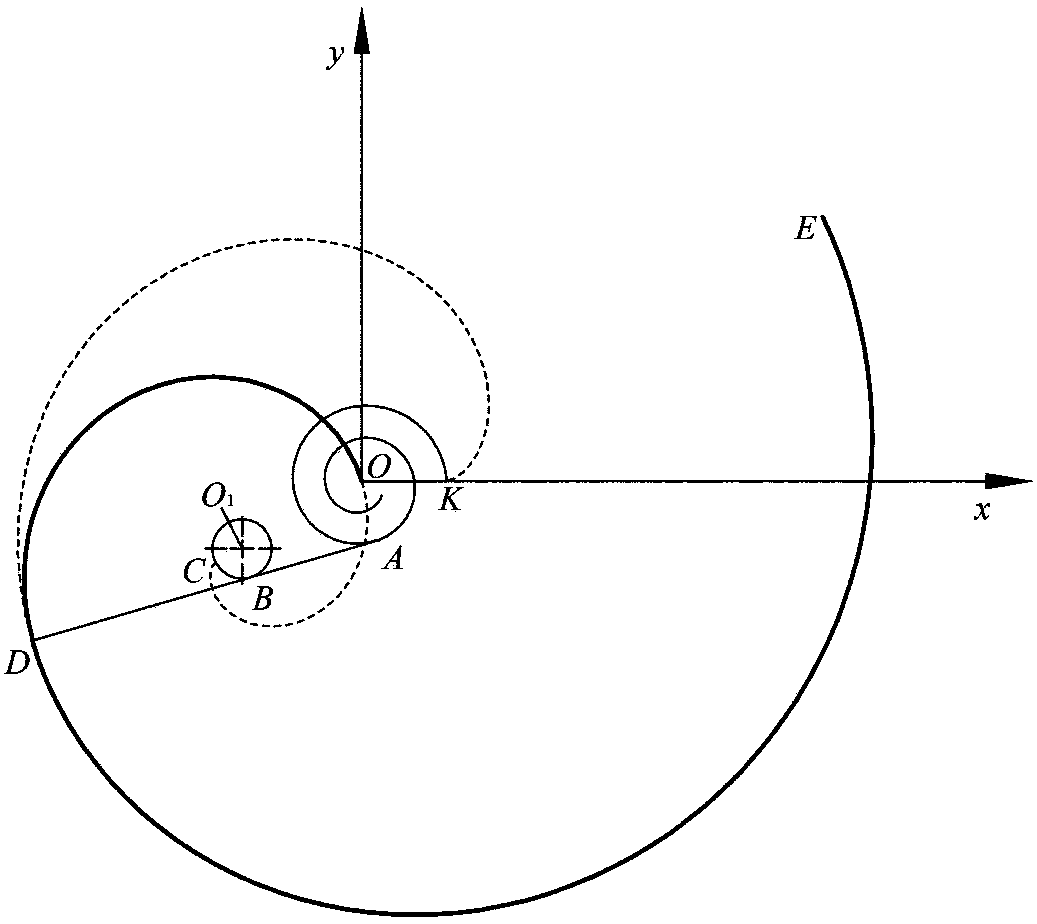

[0026] Such as figure 1 As shown, it is a full-mesh scroll tooth diagram with gradual wall thickness, and the inner and outer meshing profiles of the outer ring scroll teeth are equidistant curves of the involute of the base circle of variable diameter, and the outer spiral tooth center The inner and outer meshing profiles are equidistant curves of the circular involute; the meshing profile of the fixed scroll (1) includes 4 smoothly connected curves, which are: the equidistant curve of the first variable diameter base circle involute FH, the equidistant curve FG of the first circular involute, the equidistant curve GM of the second circular involute, and the equidistant curve MN of the second variable diameter base circle involute. The profiles of the fixed scroll (1) and the movable scroll (2) are exactly the same, that is, the fixed scroll (1) completely coincides with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com