Fastening connection assembly, fastening connection structure and rail structure

A technology for fastening connections and components, which is applied in the field of rockets and engines, and can solve problems such as no use value and difficult rotation sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

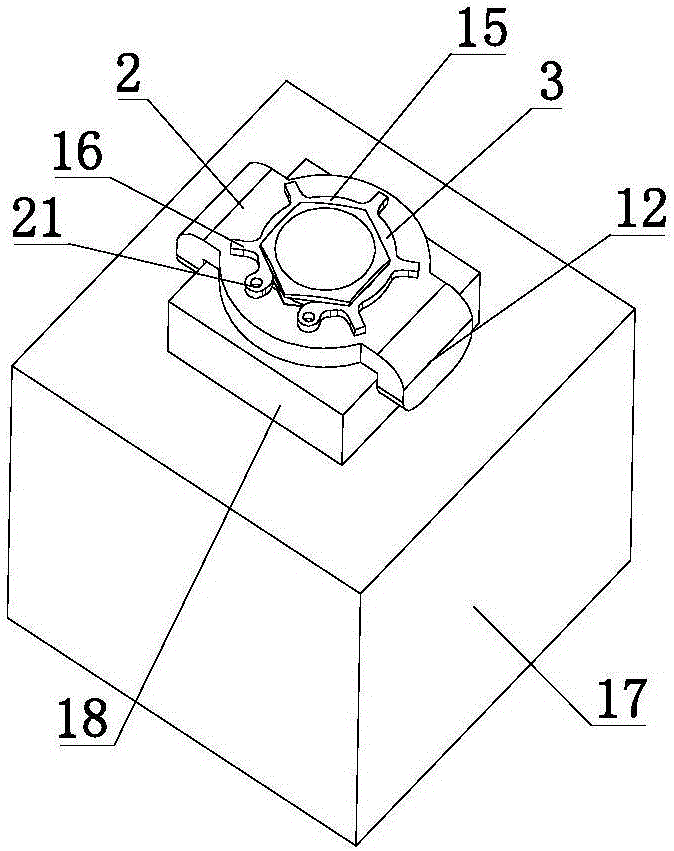

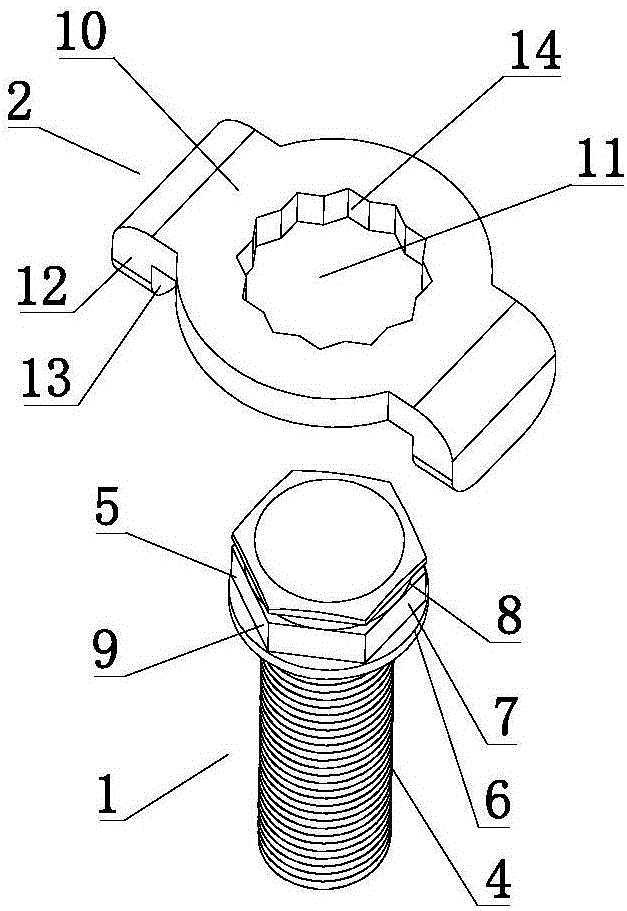

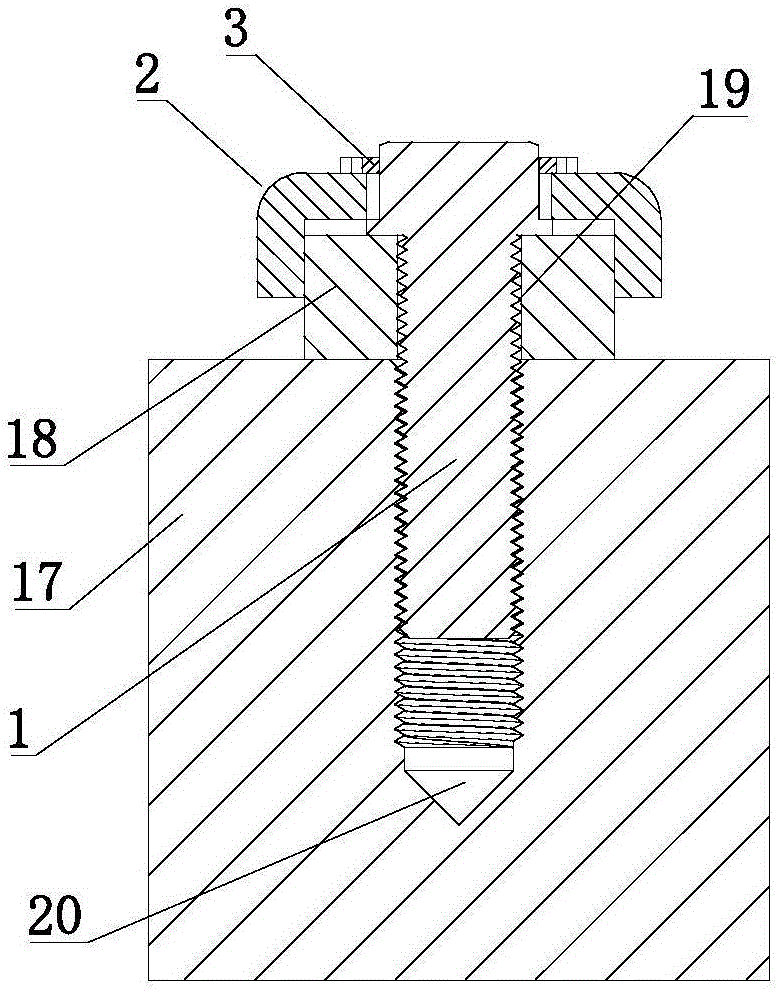

[0178] like Figure 1 to Figure As shown in 3, a fastening connection assembly includes a screw rod 1, an anti-rotation sleeve 2, and a stopper. The stopper is a snap ring 3.

[0179] The screw 1 includes an external threaded portion 4 and a rotation-stop resisting portion 5 arranged in sequence. The anti-rotation resisting portion 5 includes a cylindrical anti-rotation convex ring 6 and a regular hexagonal anti-rotation portion 7 , the anti-rotation convex ring 6 is placed between the external thread portion 4 and the anti-rotation portion 7 . The anti-rotation part 7 is provided with a locking groove 8 that cooperates with the snap ring 3 , and six planes on the outer periphery of the anti-rotation part 7 form six anti-rotation parts 9 of the screw rod arranged in the circumferential direction. The resisting ring 6 protrudes radially from the external threaded portion 4 and the anti-rotation portion 7 .

[0180] The anti-rotation sleeve 2 includes an annular anti-rotation...

Embodiment 2

[0187] like Figure 4 to Figure As shown in FIG. 7 , a fastening connection assembly includes a screw rod 31 , a lock nut 32 , and an anti-rotation sleeve 40 .

[0188] The screw 31 includes an external threaded portion 33 and an external gear-shaped anti-rotation blocking portion 34 arranged in sequence, and the anti-rotation blocking portion 34 radially protrudes from the external threaded portion 33 . A plurality of trapezoidal teeth are evenly arranged in the circumferential direction on the outer periphery of the anti-rotation resisting portion 34 , and one trapezoidal tooth forms a screw anti-rotation portion 35 .

[0189] The outer circumference of the locking nut 32 includes a regular hexagonal clamping portion 36, a conical resisting portion 37 and an axial anti-rotation boss 38 arranged on the end surface of the resisting portion 37. The axial center of the locking nut 32 is provided with a The threaded through hole 39 matched with the external threaded part 33 of 3...

Embodiment 3

[0197] like Figure 8 to Figure As shown in 10 , a fastening connection assembly includes a screw rod 401 , a locking nut 402 , an anti-rotation sleeve 403 , and a stopper, and the stopper is a resisting nut 404 .

[0198] The locking nut 402 is stepped, and includes a regular hexagonal clamping portion 405 and an external gear-shaped anti-rotation portion 406 , the anti-rotation portion 406 radially protrudes from the clamping portion 405 . A clamping portion 405 is provided to facilitate the clamping of the lock nut 402 by a wrench when the lock nut 402 is installed and disassembled. A plurality of triangular teeth evenly arranged in the circumferential direction are arranged on the outer periphery of the anti-rotation part 406 , one triangular tooth forms an outer anti-rotation part 407 of the nut, and a threaded through hole 409 is provided at the axial center.

[0199] The screw 401 includes an external threaded part 410 matched with the threaded through hole 409 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com