Deformation monitoring method based on vision measurement

A technology of deformation monitoring and visual measurement, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of insufficient number of three-dimensional reconstruction accuracy feature points, limited monitoring distance and monitoring range, difficulty in providing deformation monitoring results, etc., to achieve data Acquisition and processing synchronization, cost reduction, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

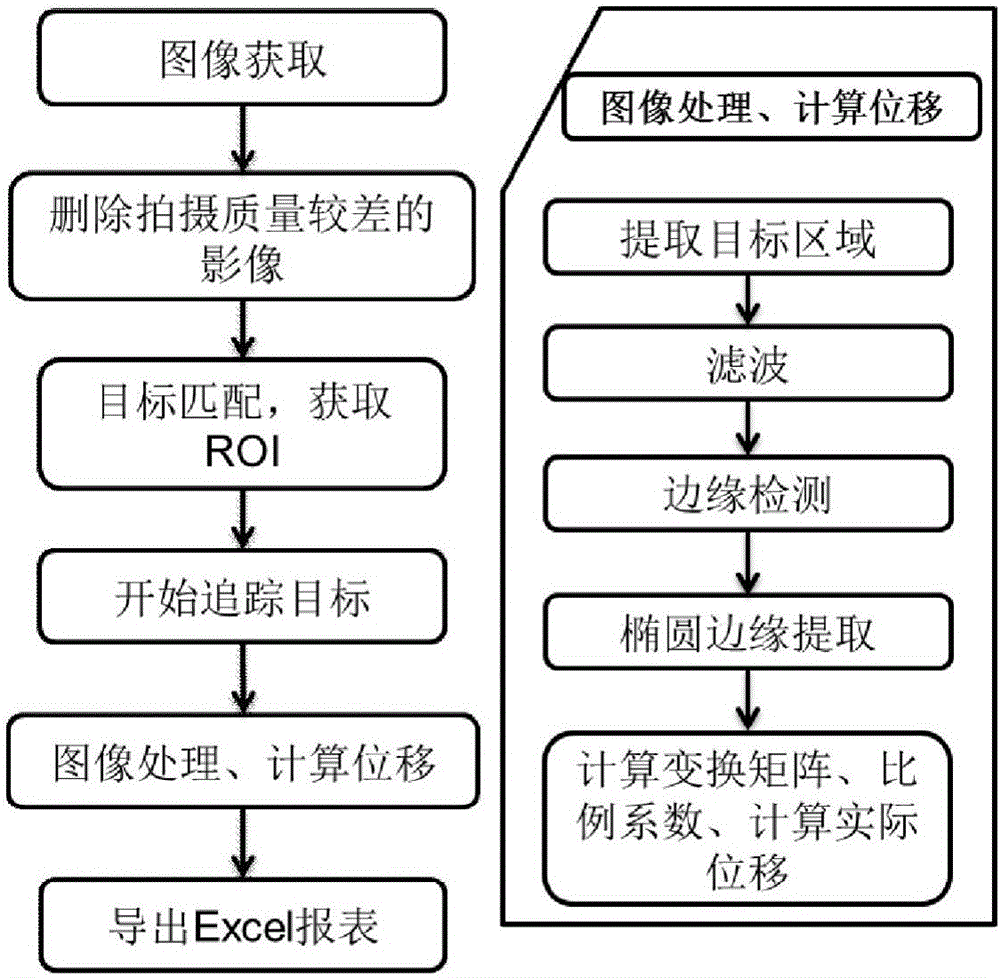

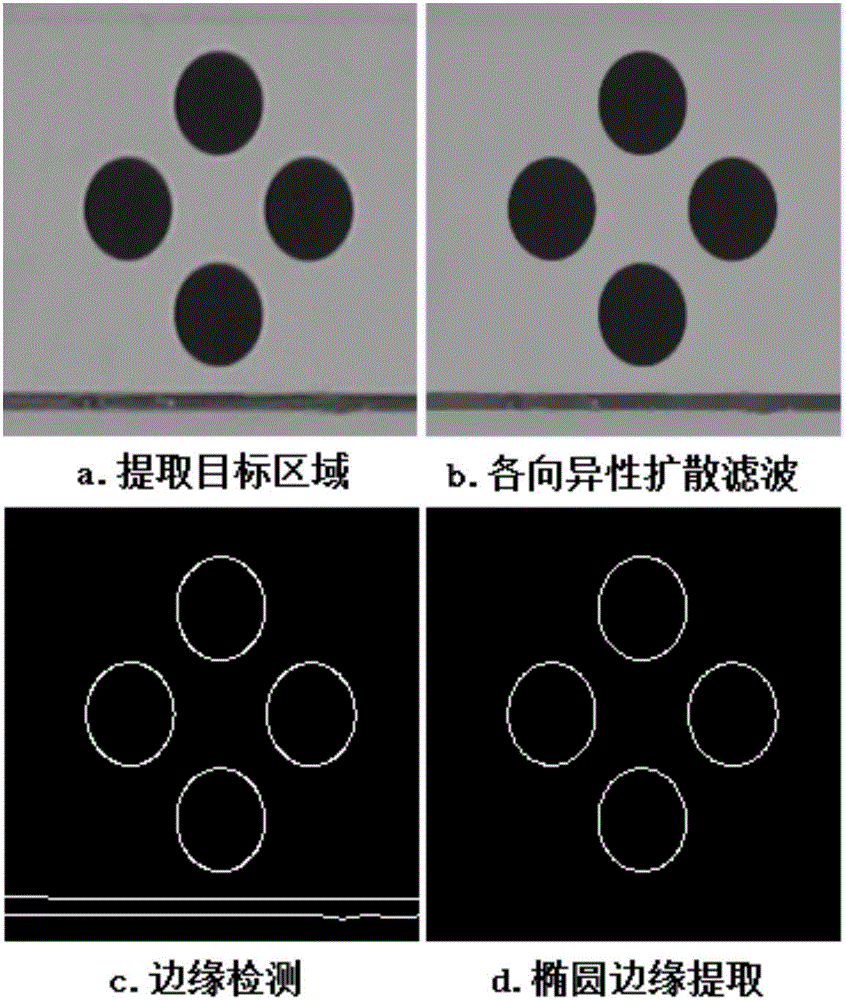

[0048] see figure 1 , the deformation monitoring method based on visual measurement of the present embodiment, comprising the following steps:

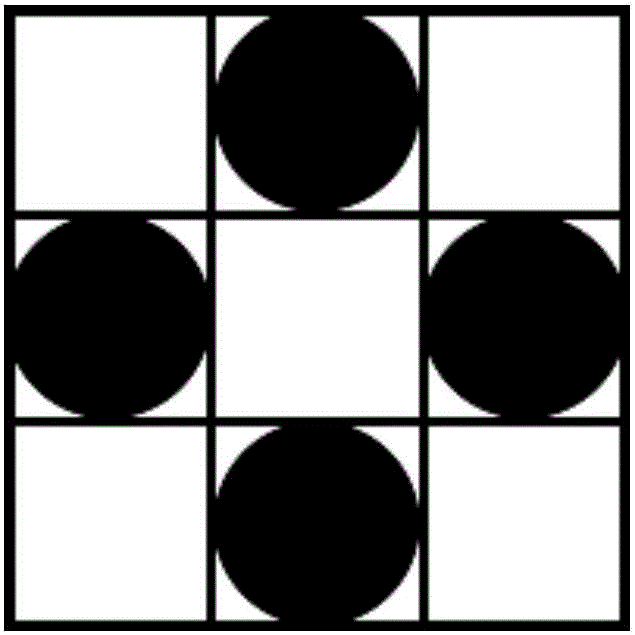

[0049] (1) Design the sign board for deformation monitoring. The sign board is a white base plate and four black discs set on the base plate. The boundaries of the discs cannot be tangent, intersected or coincident. is the first connecting line, and the connecting line between the centers of the remaining two wafers is the second connecting line, and the first connecting line and the second connecting line intersect perpendicularly. The design principle is as follows:

[0050] Assuming that the marker point moves horizontally by ΔX, the positioning accuracy is m x , the displacement accuracy is m Δx , the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com