Cable structure monitoring method based on long gauge optical fiber grating sensors

A fiber grating, long gauge technology, which is used in the testing of machine/structural components, optical testing of flaws/defects, and force measurement by measuring the change of optical properties of materials when they are stressed. Capture damage, difficult structure and other problems to achieve the effect of rapid installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

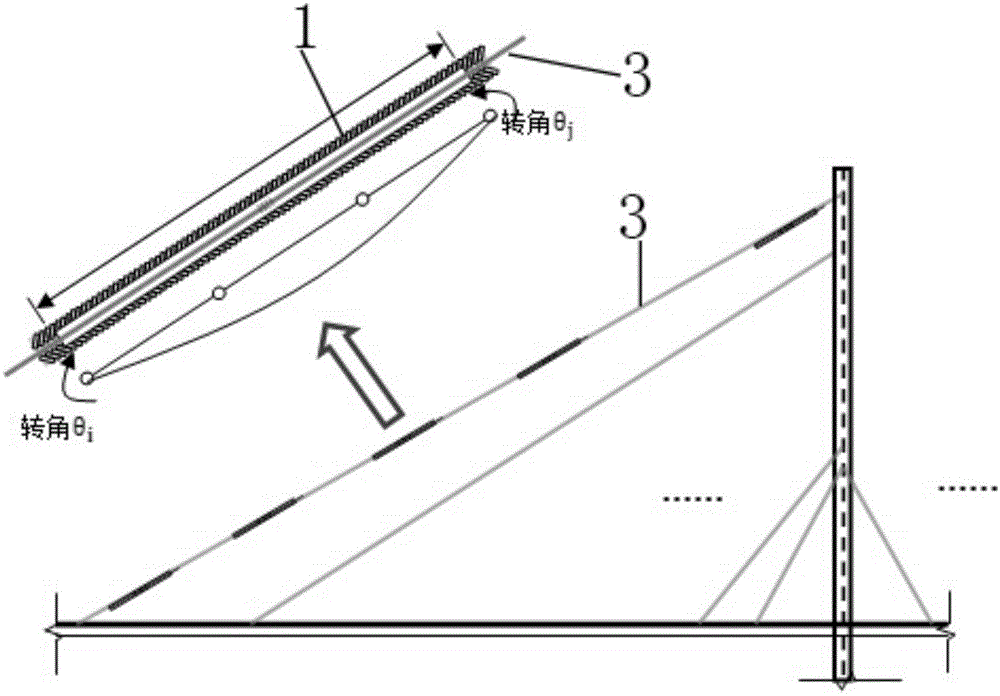

[0135] The technical scheme of the present invention will be described in detail below by taking a short cable of Jiangyin Bridge as an example.

[0136] Jiangyin Yangtze River Highway Bridge is located in Xishan, east of Huangtian Port, Jiangyin City, Wuxi City, Jiangsu Province. The main span is 1385 meters (328+1385+295), the sling spacing is 16m, and the side slings are 20.5m from the center line of the tower. The total bridge is 85 pairs. Sling, choose one of the slings as the research object. The length of the selected sling is 6.3m, the diameter is 0.105m, and the elastic modulus of the sling is 1.4×10 5 MPa, the material density is 7800kg / m 3 , Each order of modal damping is equal, the value is 0.05. The tensile force of the selected cable can be checked for the health monitoring data of Jiangyin Bridge, and it is found to be T=526kN.

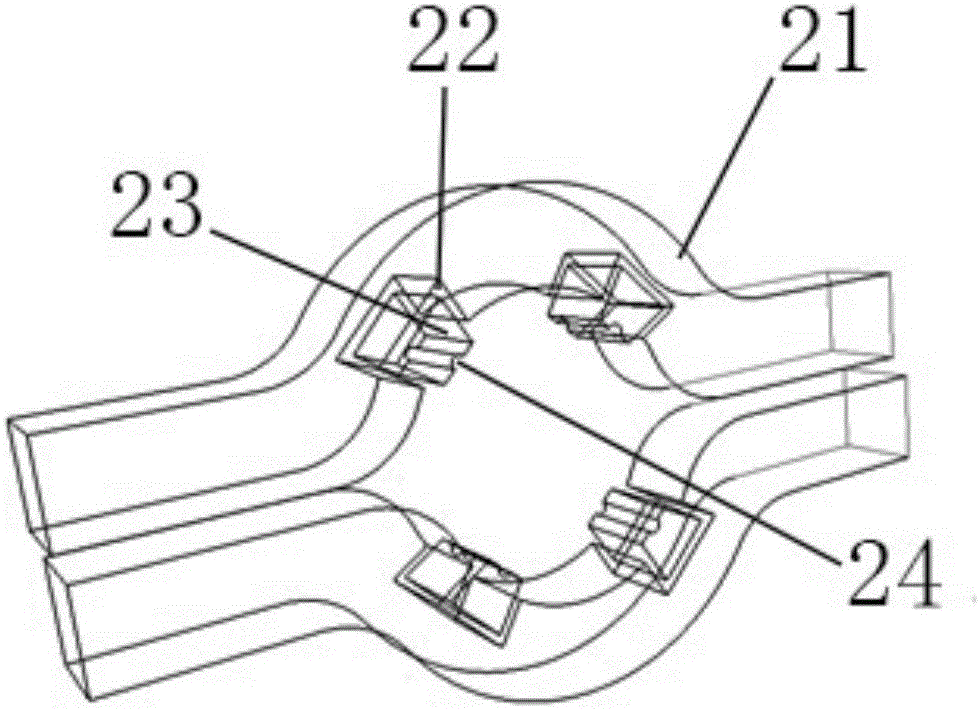

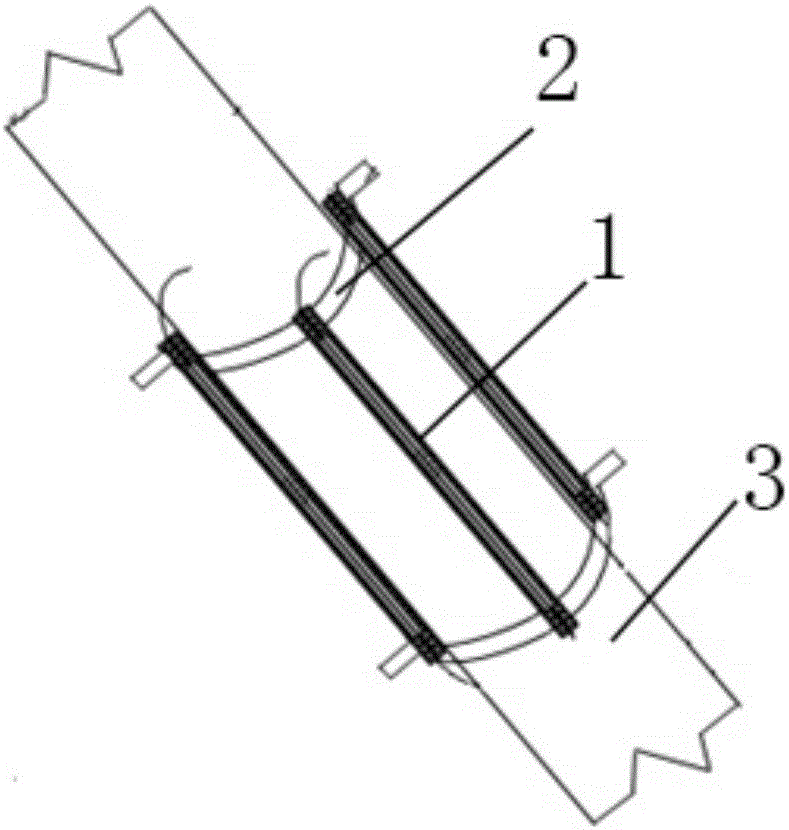

[0137] Step 1: Use the developed cable clip to arrange the health monitoring system on the structure

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com