Internal pipeline defect detecting device, detecting method and start setting method of cameras

A detection device and detection method technology, applied in the direction of measurement device, rotorcraft, motor vehicle, etc., can solve the problems of high cost, slow detection speed, limited application range of detectors, etc., to eliminate potential safety hazards and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

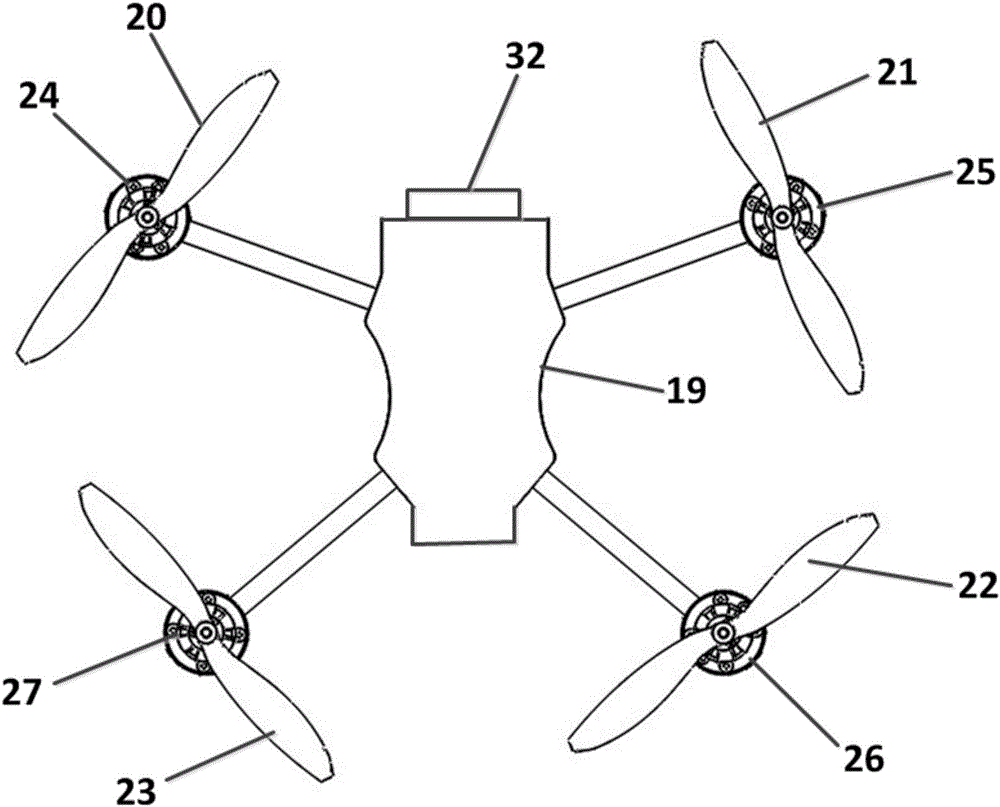

[0063] The invention includes an inner aircraft and an outer aircraft: the inner aircraft collects pipes with different inner diameters, and after collection, the image data is transmitted to the outer aircraft, and then transmitted to the cloud via the outer aircraft.

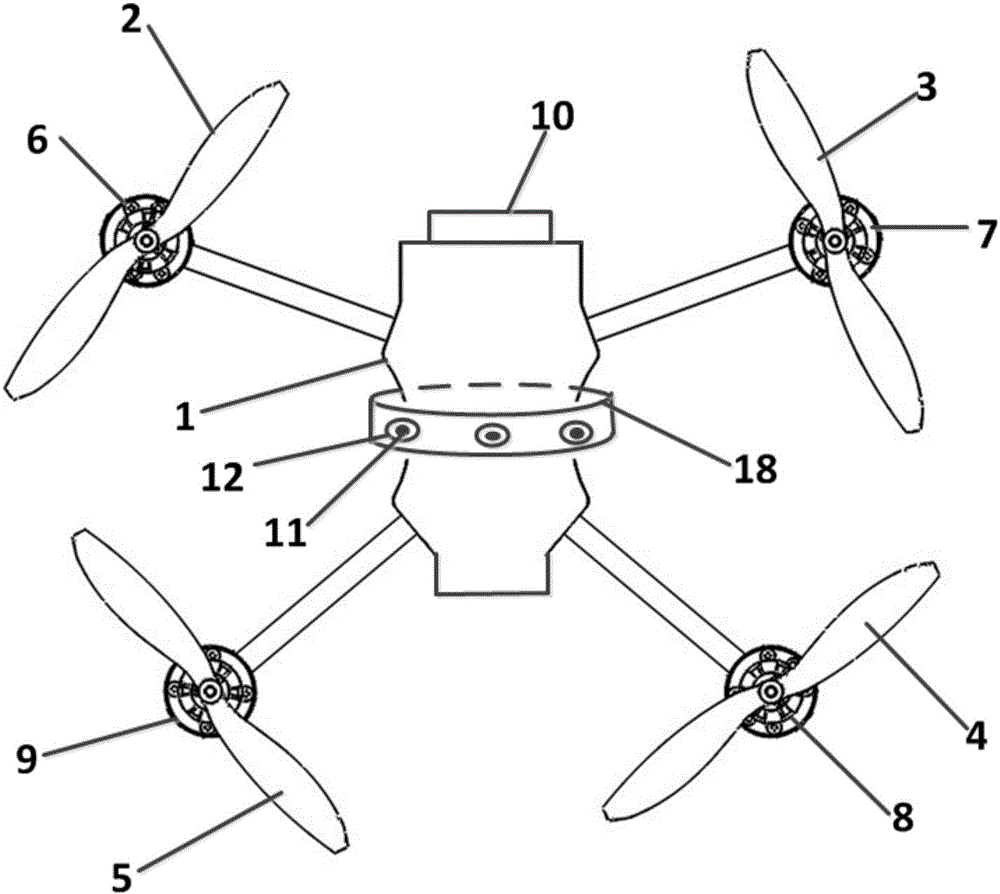

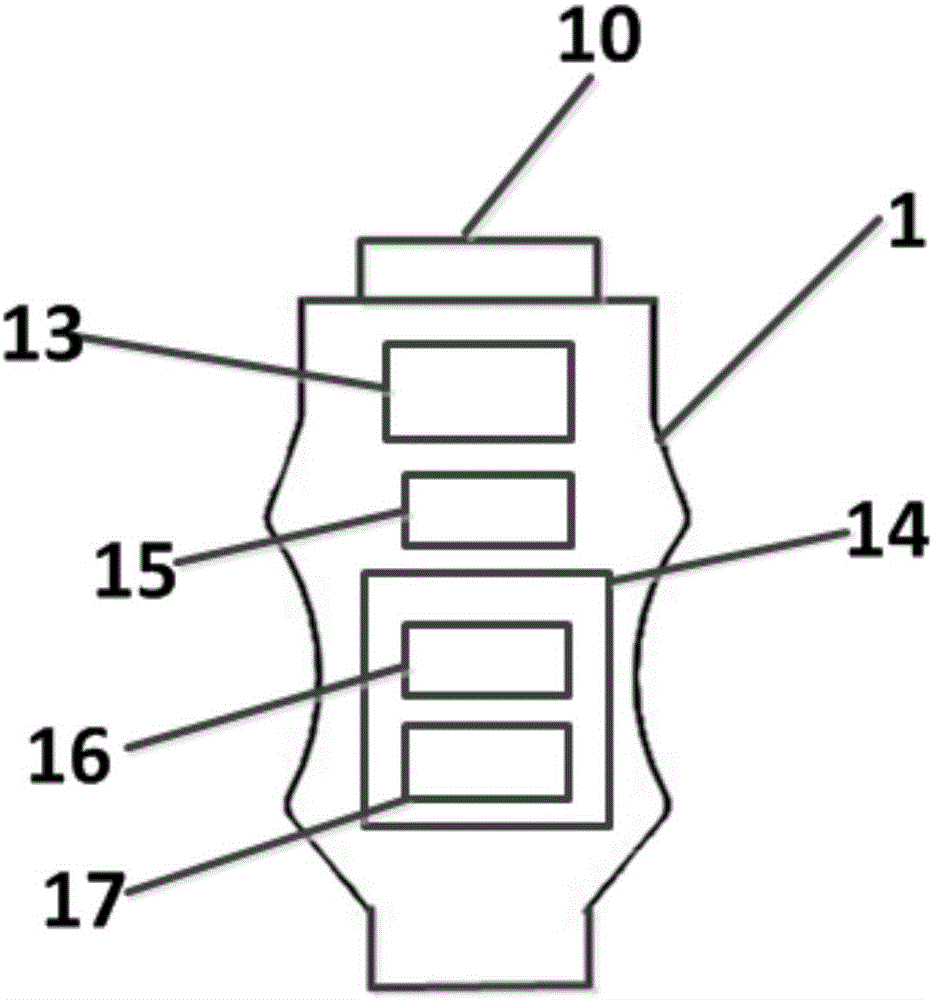

[0064] Such as figure 1 and figure 2 As shown, the inner aircraft includes an inner aircraft fuselage 1 and inner aircraft propellers 2, 3, 4, 5, inner aircraft motors 6, 7, 8, 9, inner aircraft main boards 14 and inner aircraft propellers installed on the inner aircraft fuselage 1. Battery 13; four inner aircraft propellers 2, 3, 4, 5 are installed on the inner aircraft fuselage 1, and the inner aircraft propellers 2, 3, 4, 5 are respectively connected with respective inner aircraft motors 6, 7, 8, 9, The internal flight propeller is driven by the internal aircraft motor to rotate and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com