Method for testing first startup of first machines of pumped storage power stations

A technology of pumped storage power station and test method, which is applied to the testing of machines/structural components, measuring electricity, and measuring electrical variables, etc., which can solve problems such as no guidance plan and short test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

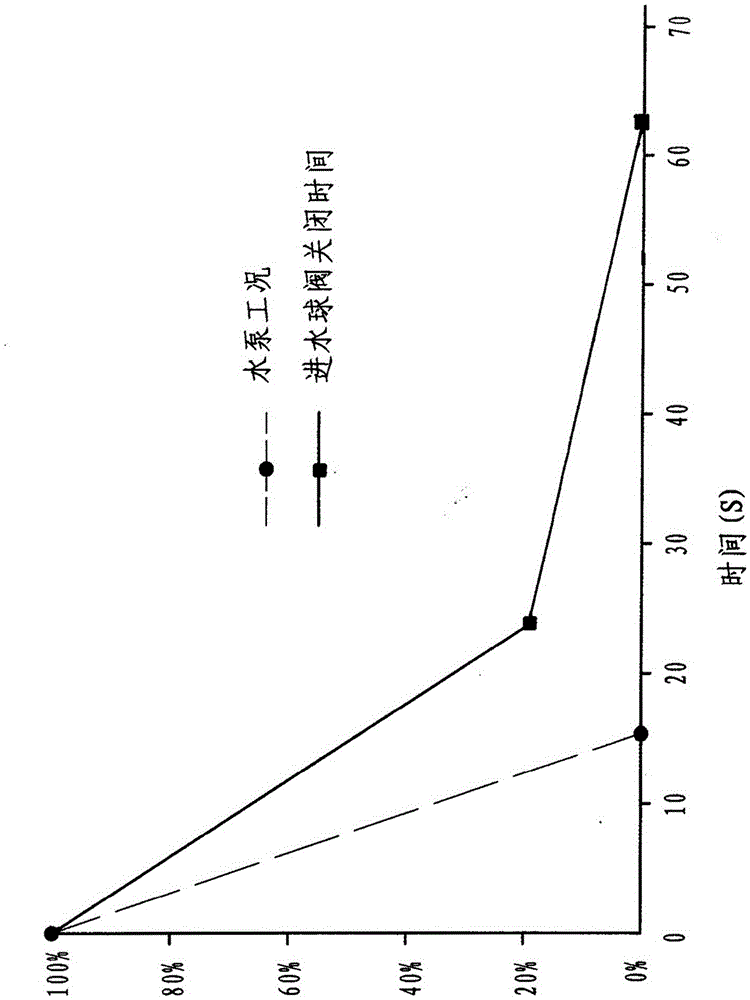

[0085] Embodiment: A test method for the first start-up of the first machine of a pumped storage power station. The test method for the first start-up of the first machine is a test method for starting the whole group of water pumps. Condition test, working condition conversion test and accident shutdown test.

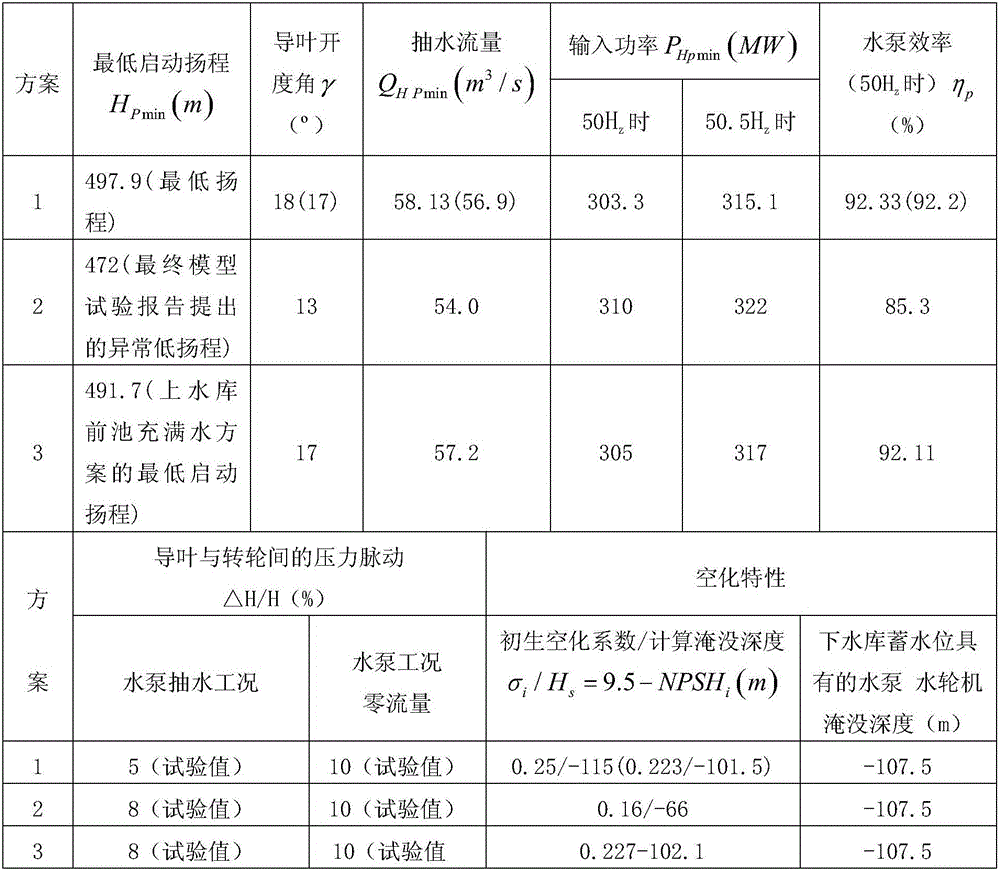

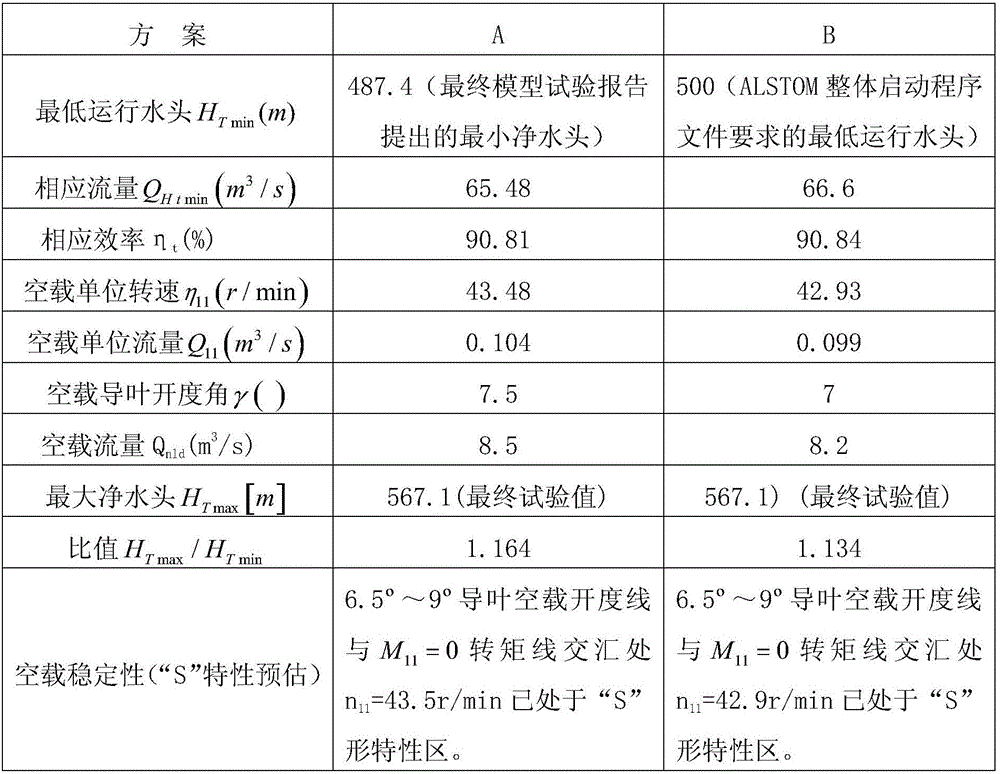

[0086] The operating parameters (main characteristic hydraulic parameters) of the whole group start-up test under the first water pump working condition of the first machine are as follows: The water volume is 43,910 m 3 (The water filling of the upper reservoir is completed by the 6 water supply pumps of the construction water supply system of the upper reservoir and the 2 upper reservoir water filling pumps in the factory building. The water filling flow of the 6 construction water supply pumps of the upper reservoir for the upper reservoir filling is 260m 3 / s, the corresponding motor power is 411kW); the working lift of the water filling pump on the upper reservoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com