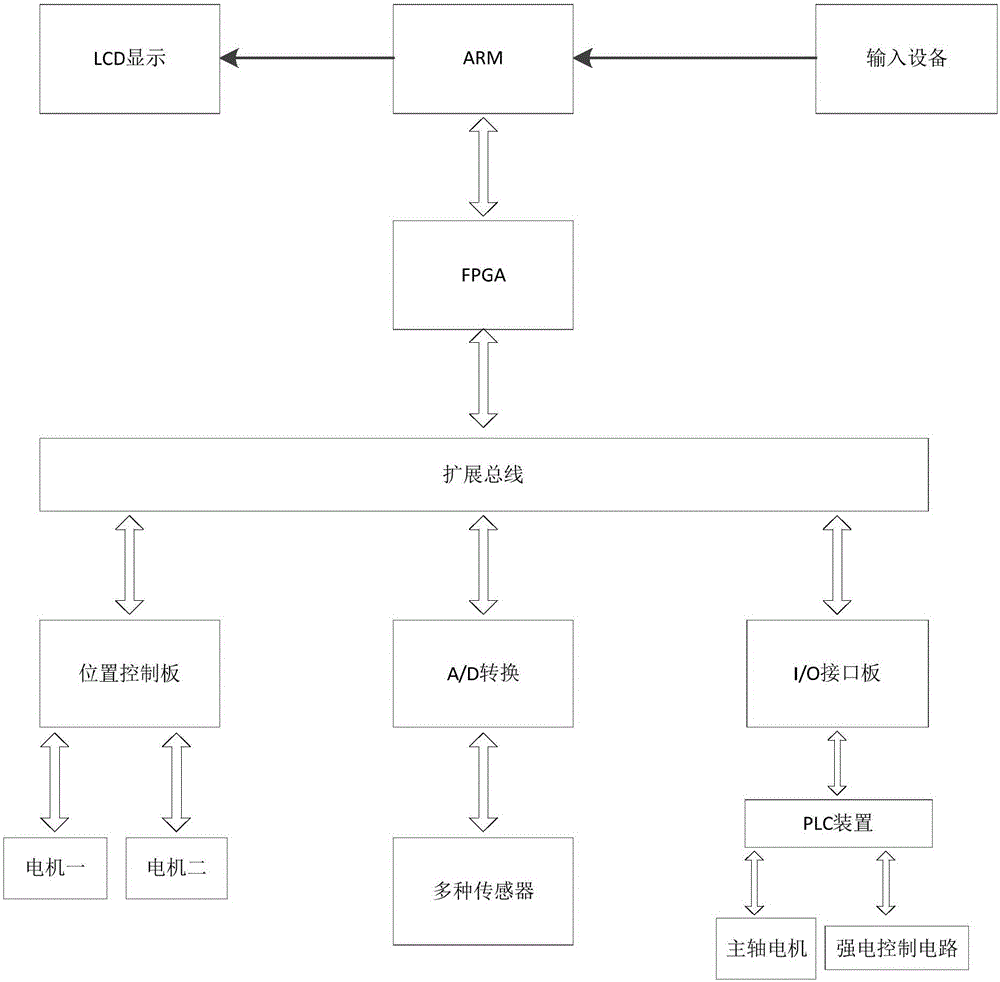

Combined woodworking processing equipment with independent A/D (analog/digital) conversion module

A conversion module and composite processing technology, applied in control/regulation systems, instruments, digital control, etc., can solve the problems of increased data processing load, affecting the response speed of the control system, large size, etc., to achieve closed-loop control, efficient intelligent sensing - Controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] Composite processing is one of the most popular processing technologies in the world in the field of mechanical processing, and it is an advanced manufacturing technology. Composite processing is to realize several different processing technologies on one machine tool. Turn-mill-drilling machining centers are usually used for cutting metal materials. In the woodworking industry, due to the huge difference in the materials of wood and metal, the turning, milling and drilling compound machining center used for metal processing cannot be directly applied to the wood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com