Calculation method for steady creep rate fitting equation of metal material

A technique for steady-state creep and fitting equations, which is used in calculations, computer-aided design, design optimization/simulation, etc. It can solve problems that affect the accuracy of the steady-state creep rate fitting equation results, and the hyperbolic sine model cannot be accurately fitted. It can solve the problems of combined creep rate and inability to calculate the steady-state creep rate of materials, so as to achieve the effect of improving applicability and accuracy, good fitting degree, and reducing the influence of creep rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

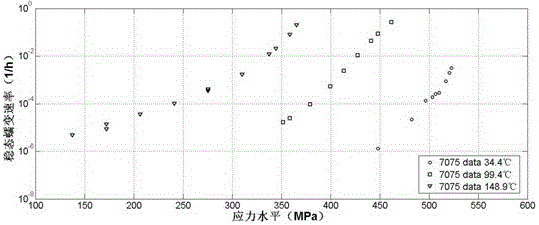

[0058] The high-strength aluminum alloy 7075 aluminum alloy plate (T6 state) was selected as the research object, and the sampling direction of the creep sample was the short transverse direction in the plate (perpendicular to the extrusion direction of the extruded plate), and the sample size referred to GB / T 2039-1997 "Metal Tensile Creep and Endurance Test Methods". The experimental temperature levels were 34.4°C, 99.4°C, and 148.9°C respectively, and a total of 31 effective creep data were obtained. For the data distribution, see figure 2 .

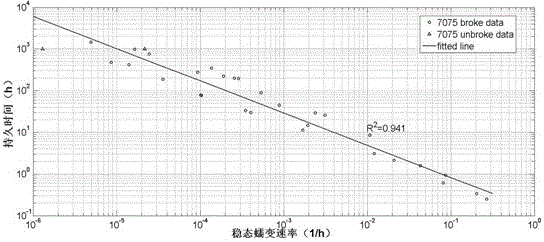

[0059] (i) The steady-state creep rate and durable rupture time of the 7075 aluminum alloy samples at different temperatures are marked in On a log-log plot, such as image 3 shown. Calculated by linear fitting The fitted straight line expression of , where the linear fit R 2 =0.941, the fitting situation is as follows image 3 shown;

[0060] (ii) According to the Monkman-Grant relationship, using the steady-state creep r...

Embodiment 2

[0072] The high-strength aluminum alloy 7075 aluminum alloy plate (T6 state) was selected as the research object, and the sampling direction of the creep sample was the short transverse direction in the plate (perpendicular to the extrusion direction of the extruded plate), and the sample size referred to GB / T 2039-1997 "Metal Tensile Creep and Endurance Test Methods". The experimental temperature levels were 34.4°C, 99.4°C, and 148.9°C respectively, and a total of 31 effective creep data were obtained. For the data distribution, see figure 2 .

[0073] (i) The steady-state creep rate and durable rupture time of the 7075 aluminum alloy samples at different temperatures are marked in On a log-log plot, such as image 3 shown. Calculated by linear fitting The fitted straight line expression of , where the linear fit R 2 =0.941, the fitting situation is as follows image 3 shown.

[0074] (ii) According to the Monkman-Grant relationship, using the steady-state creep r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com