Tooth shape matching design method for timing chain wheel and timing chain of engine

A timing sprocket and design method technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as unsound methods, large friction work between the chain and the sprocket tooth shape, and the chain is easy to skip teeth, etc., to achieve Simple design, large friction work and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

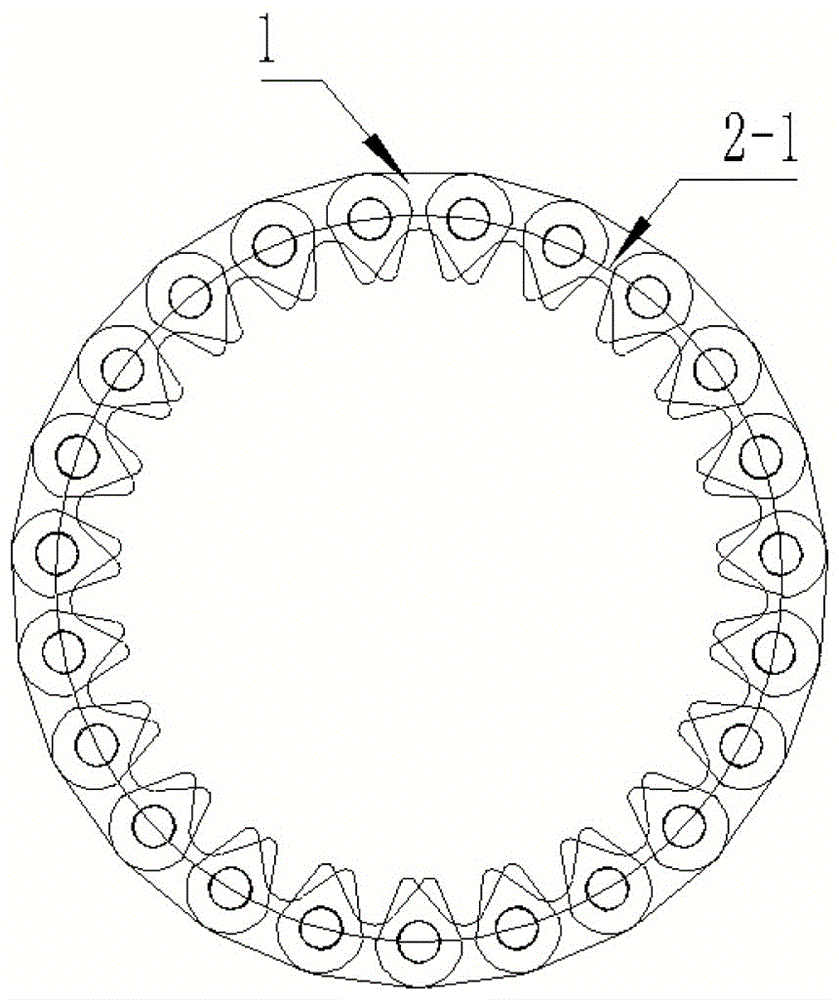

[0025] Attached to the following Figures 1 to 9 Embodiments of the present invention are described in further detail. like Figures 1 to 9 As shown in the figure, a design method for matching the tooth shape of an engine timing sprocket and a timing chain, the specific design steps are as follows: the sprocket pitch is 6.35mm, and the number of teeth is 23 teeth.

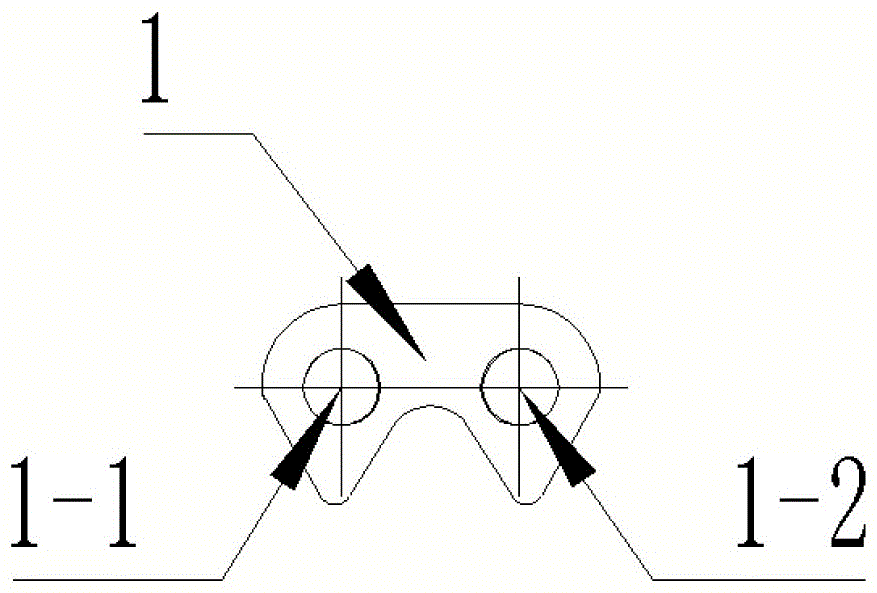

[0026] 1. Establish a two-dimensional model of the tooth shape of the chain plate

[0027] like figure 1 As shown in the figure, the structure of the chain plate 1 is set, and the model is established.

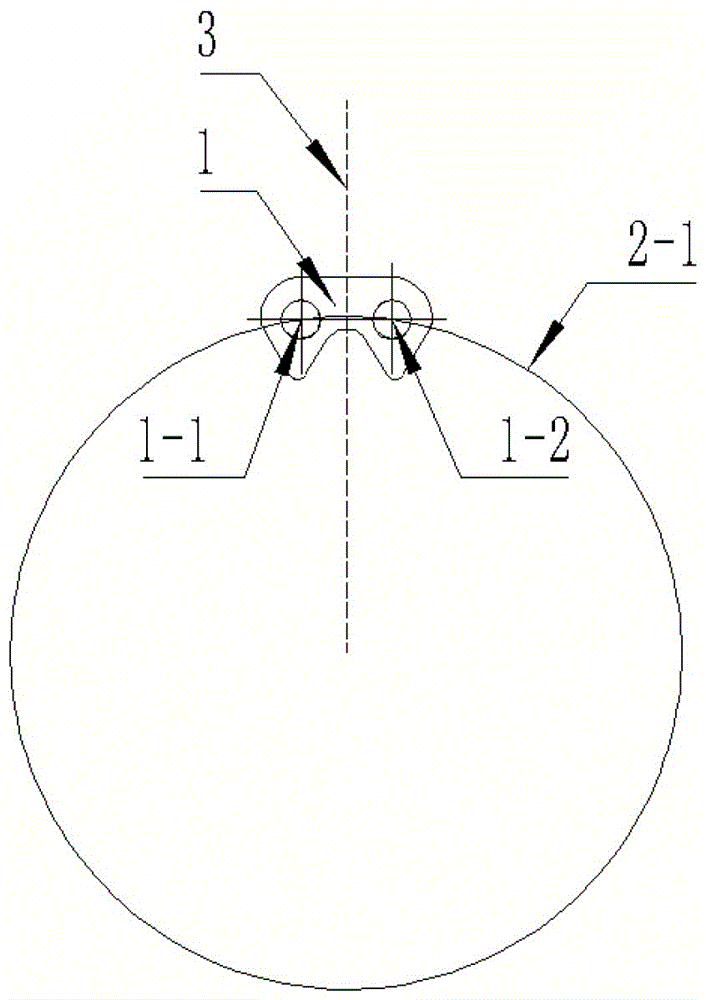

[0028] 2. Drop the chain, drop the chain plate onto the pitch circle of the sprocket

[0029] like figure 2 and 3 As shown, from the relationship between the chain tooth profile and the sprocket tooth profile, the formula D=P / sin (180° / Z) can be used to calculate the sprocket pitch circle 2-1 when the sprocket is working, and the diameter D= 46.63, with the center line 3 of the chain plate as the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com