Tubular conductive piece and conductive device by employing the same

A technology for conductive parts and conductive tubes, applied in the field of conductive equipment and tubular conductive parts, can solve the problems of easy mixing of foreign objects in conductive tubes, discharge accidents, etc., and achieve the effect of shortening assembly cycle, improving work efficiency, and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

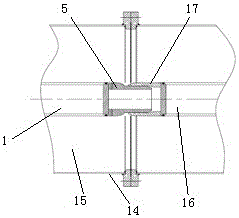

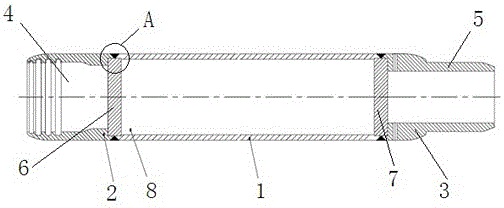

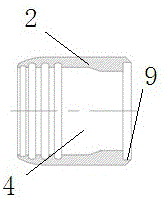

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. A specific embodiment of a conductive device of the present invention, such as Figure 1 to Figure 7 As shown, it includes a housing 14 and a plurality of end-to-end tubular conductive members arranged in the housing 14, and one of them is taken as an example for detailed description. The tubular conductive member includes a tube body, and the tube body includes a conductive tube 1 , the first tubular joint 2 arranged at one end of the conductive pipe 1 and the second tubular joint 3 arranged at the other end of the conductive pipe 1, a blocking plate is arranged between the conductive pipe 1 and each tubular joint for blocking The inner holes at both ends of the conductive pipe 1 make the inner holes of the conductive pipe 1 form an independent closed space and isolate it from the air chamber 15 of the equipment for the assembly of the tubular conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com