Short-circuit winding based vibration suppression method of iron core reactor

A vibration suppression and reactor technology, applied in transformer/inductor noise damping, transformer/inductor coil/winding/connection, etc. problem, to achieve the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

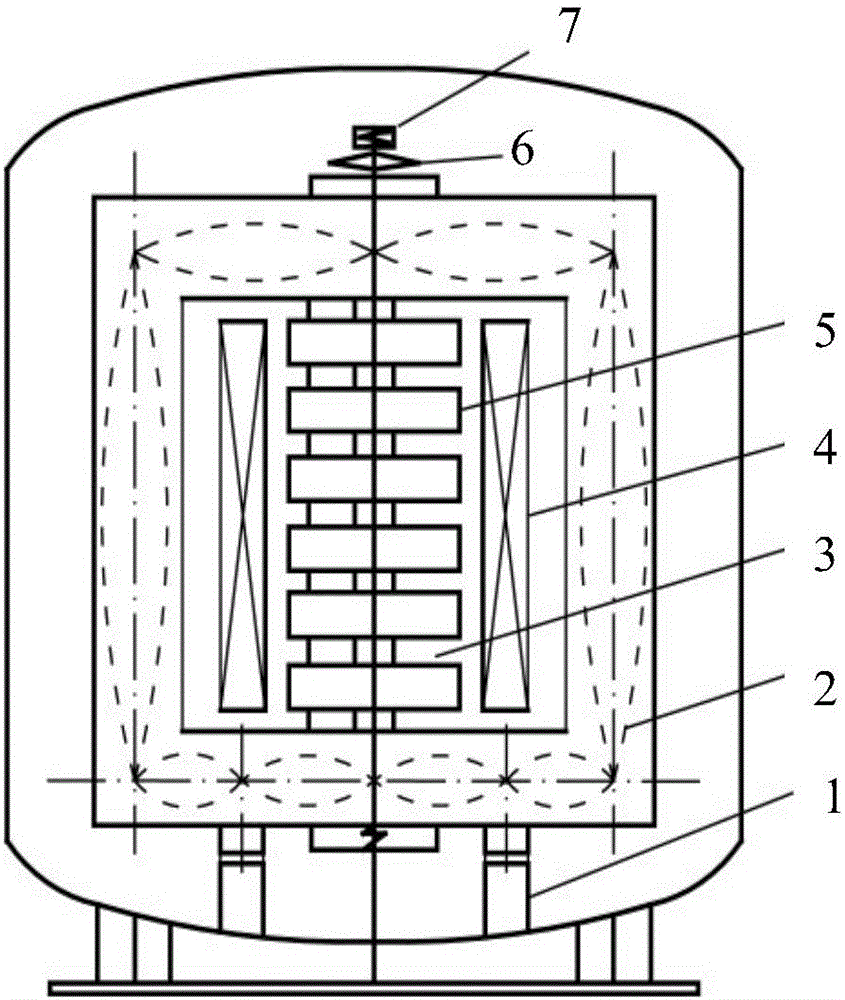

[0023] The source of vibration and noise during the operation of the iron core reactor is the iron core. Under the action of alternating current in the magnetic circuit of the iron core, the electromagnetic force on the silicon steel sheet of the iron core will cause a complex magnetostrictive effect on the silicon steel sheet, so that the size of the silicon steel sheet will change. Minor changes. If the natural vibration frequency of the fuel tank and other accessories of the reactor is consistent with the vibration frequency from the iron core, resonance will occur, which will aggravate the vibration of the reactor and increase the noise.

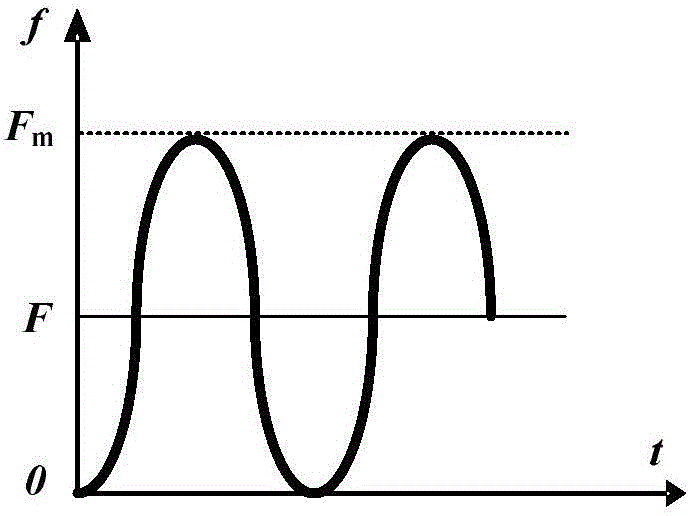

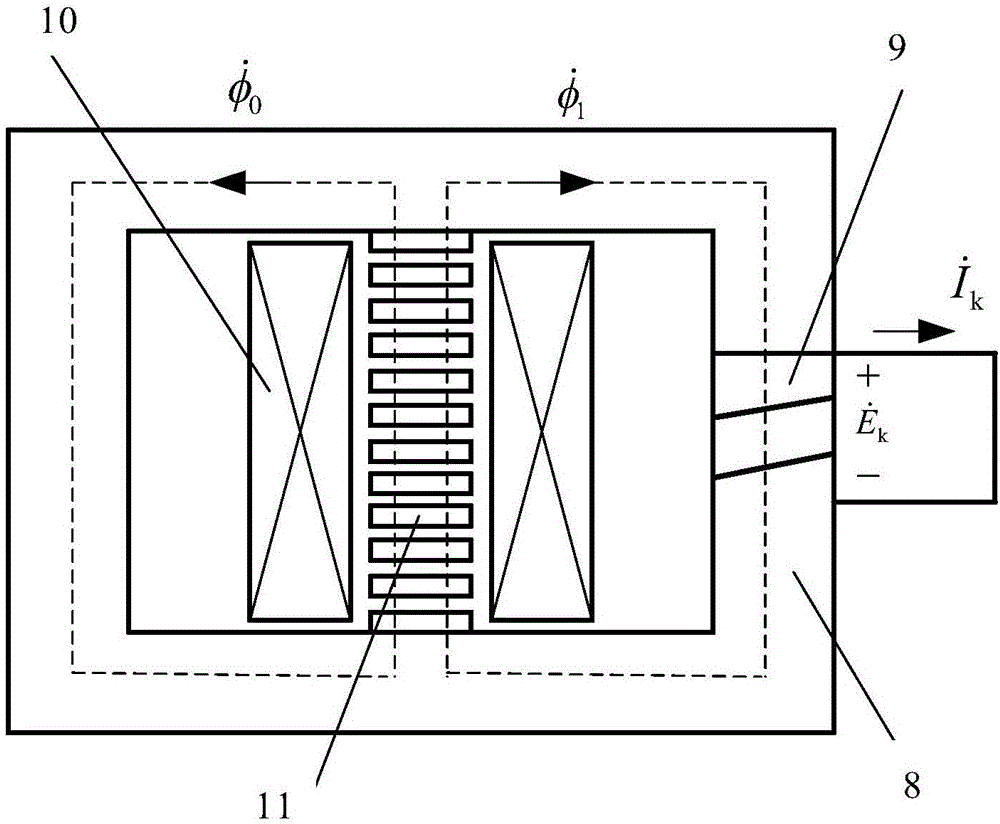

[0024] When the reactor works, there will be a magnetic field circulating in the iron core. Because there is an air gap between the iron core cakes, electromagnetic forces will be generated on the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com