Array substrate and display device

A technology for array substrates and display devices, which is applied to semiconductor/solid-state device components, instruments, semiconductor devices, etc., and can solve problems such as cumbersomeness, life expectancy, and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

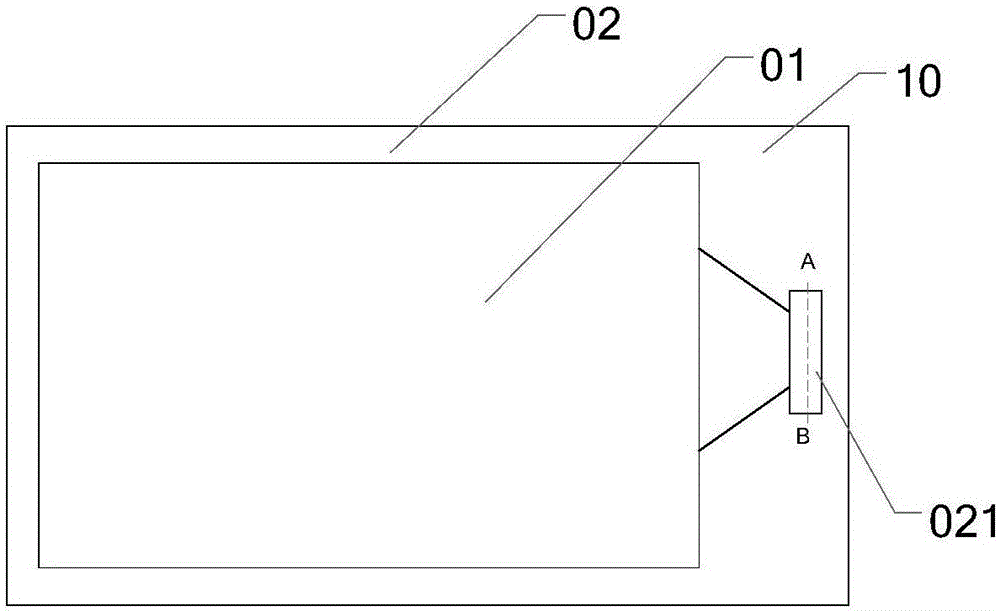

[0034] This embodiment provides an array substrate 10, such as image 3 As shown, it includes a display area 01 and a peripheral area 02 arranged on at least one side of the display area 01, image 3 A bonding area 021 located in the peripheral area 02 is also shown in . For example, bonding area 021 can be configured to connect external circuits. For example, the bonding area 021 can be configured to be connected with a driver IC, for example, can be used as a lead-out area of a flexible circuit board.

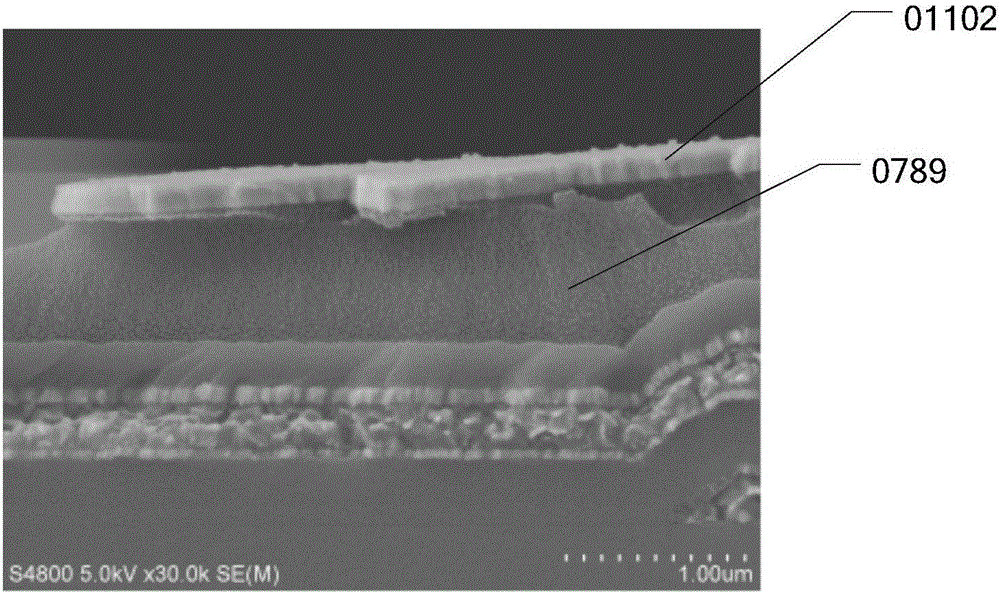

[0035] Such as Figure 4 As shown, the array substrate includes a base substrate 101 and a first conductive layer 106 and a second conductive layer 110 sequentially arranged on the base substrate 101, and at least two conductive layers are arranged between the first conductive layer 106 and the second conductive layer 110 a passivation layer formed continuously in a direction perpendicular to the base substrate 101. A first conductive layer 106 , at least two passivatio...

Embodiment 2

[0057] Different from the first embodiment, the first conductive layer 106 , at least two passivation layers and the second conductive layer 110 are only provided in the display area 01 . Can refer to Figure 6f Display area 01 on the left. The first conductive layer 106 includes a plurality of first conductive structures 1060 insulated from each other, and the first conductive structures 1060 can be source electrodes 1062 and drain electrodes 1061 . The second conductive layer 110 includes a plurality of second conductive structures 1102 insulated from each other, and the second conductive structures 1102 may be pixel electrodes. The second conductive structure 1102 may be electrically connected to the first conductive structure 1060 through via holes penetrating at least two passivation layers.

[0058] In one example, the second conductive structure 1102 can also be a common electrode. When the second conductive structure 1102 is a common electrode, the second conductive...

Embodiment 3

[0062] This embodiment provides a display device, including any one of the array substrates described in Embodiments 1 to 2.

[0063] For example, the display device includes a liquid crystal display device or an organic light emitting diode display device, but is not limited thereto.

[0064] For example, the display device may include display devices such as televisions, digital cameras, mobile phones, watches, tablet computers, notebook computers, and navigators.

[0065] The following description will be made by taking the display device as an example of a liquid crystal display device. When the display device is a liquid crystal display device, various modes such as ADS, HADS, TN, and VA can be used, which is not limited in this embodiment.

[0066] In an example, such as Figure 7As shown, the array substrate 10 and the opposite substrate 20 can be boxed together, and a liquid crystal layer (not shown in the figure) is formed therebetween, exposing the bonding region 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com