A precision miniature packaging device capable of projecting graphics, logos and symbols

A packaged device and sophisticated technology, applied in the field of precision micro-packaged devices, can solve the problems of unreduced cost, no projection function, large luminous angle, etc., achieve cost and application field expansion, increase luminous effect, and various graphics effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

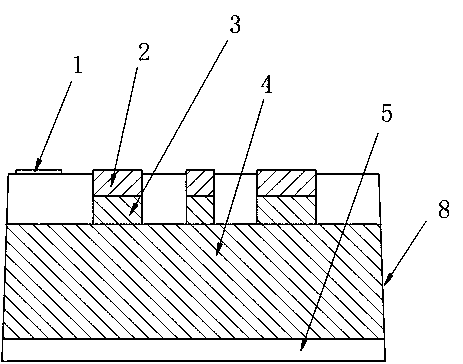

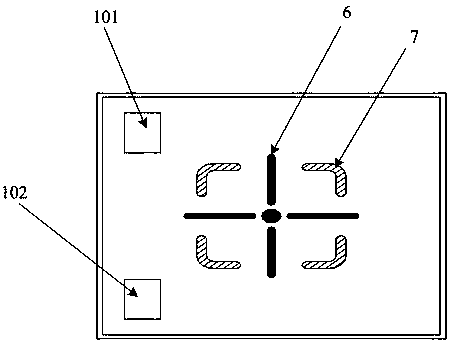

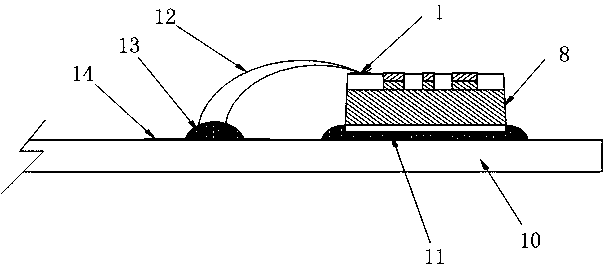

[0028] This embodiment provides a precision micro-encapsulation device capable of projecting graphics, logos and symbols, such as figure 1 and Figure 4 As shown, the precision micro-packaged device includes a light-emitting crystal 8, and the light-emitting crystal includes a substrate. The substrate is set as sapphire, silicon carbide substrate and silicon substrate, etc., and the material layer 4 is set on the substrate by growing the PN junction On the material layer 4, after the PN junction of the light-emitting diode is grown, the excess part is removed by laser beam and other processing methods to retain the required pattern shape, and at the same time, the excess light is shielded by means of electrode covering, that is, the light emission of the required pattern The PN junction of the diode is arranged on the substrate material laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com