Dynamic primary thermal power generating unit frequency modulation control method for power grid with high wind power penetration rate

A technology of thermal power units and control methods, applied in the direction of reducing/preventing power oscillation, etc., can solve problems such as frequency stability and adverse effects of fluctuating systems, and achieve the effect of enhancing regulation ability and weakening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

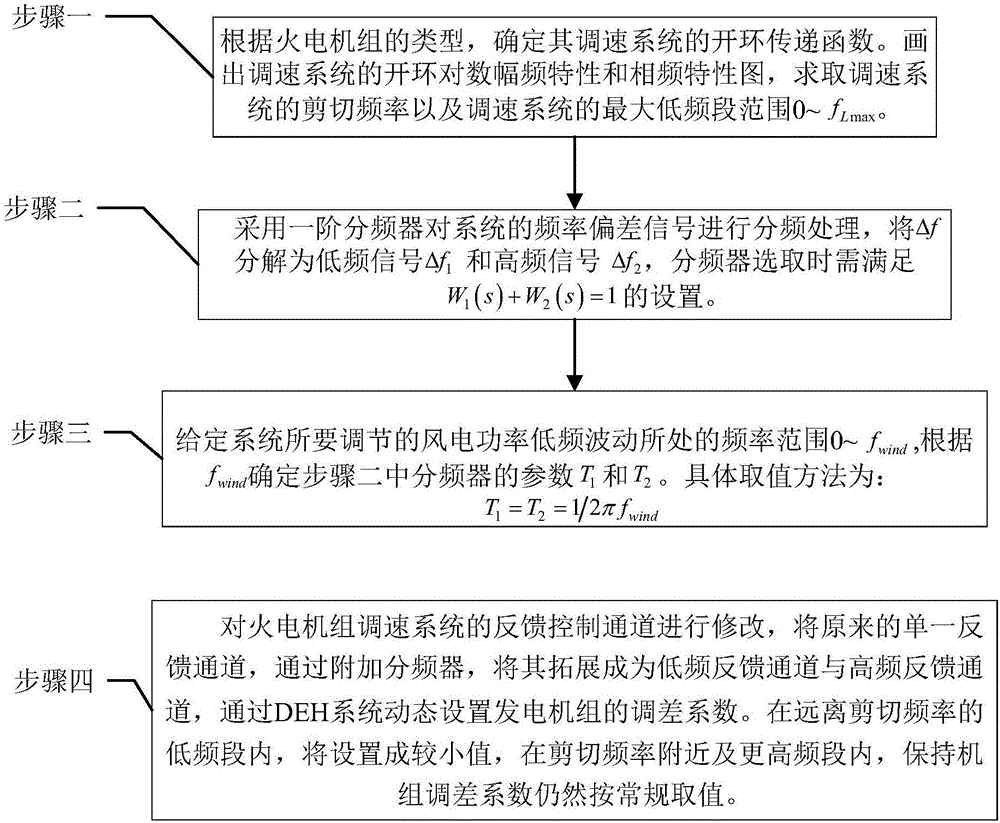

[0024] Specific implementation mode one: as figure 1 As shown, a dynamic primary frequency regulation control method for thermal power units used in high wind power grids includes the following steps:

[0025] Step 1: According to the type of thermal power unit, determine the open-loop transfer function G(s) of the speed control system, draw the open-loop logarithmic amplitude-frequency characteristic and phase-frequency characteristic diagram of the speed control system according to G(s), and obtain When δ=0.02, the frequency ω corresponding to the place where the amplitude-frequency characteristic curve of the speed control system exceeds 0dB c And the maximum low frequency range of the speed control system is 0~f Lmax , where f Lmax It is the corresponding frequency when the logarithmic phase-frequency characteristic curve of the speed control system is equal to -110°;

[0026] Step 2: Use the first-order frequency divider to perform frequency division processing on the ...

specific Embodiment approach 2

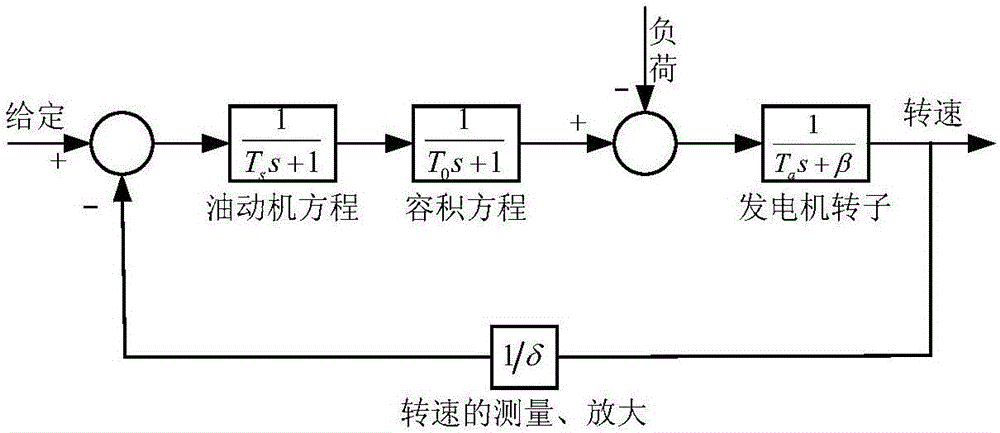

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the open-loop transfer function G(s) in the step one is specifically:

[0032] When the thermal power unit is a condensing steam turbine unit, according to figure 2 The open-loop transfer function G(s) of the condensing speed control system can be obtained as follows:

[0033] Condensing type:

[0034]

[0035] where the T s is the time constant of the oil motor, T 0 is the time constant of the volume equation, T a is the generator rotor time constant, s=jω, j is an imaginary number, and ω is the angular frequency.

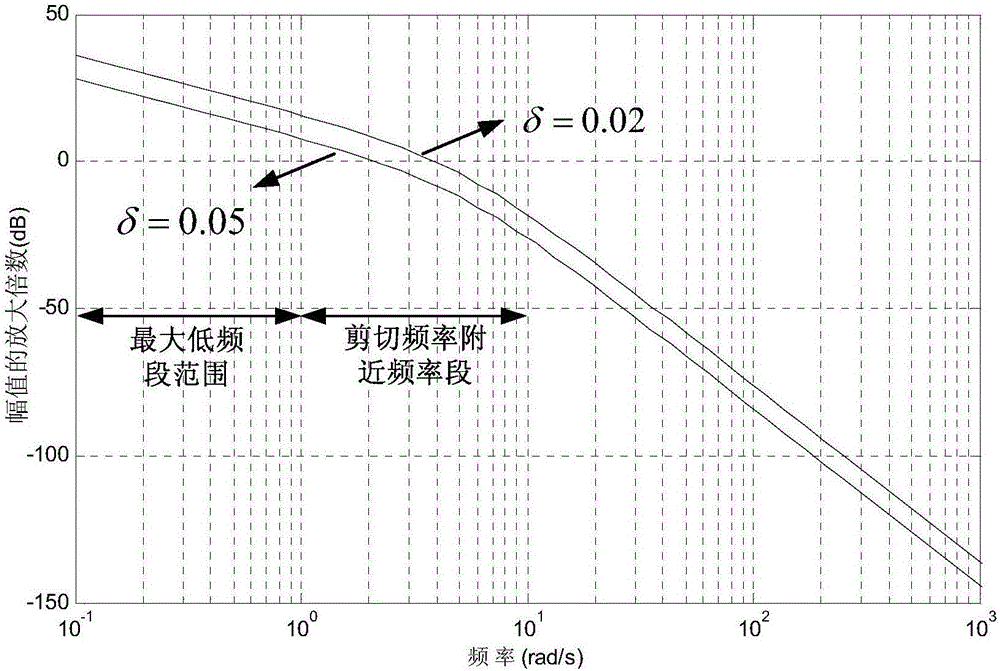

[0036] According to G(s), draw the open-loop logarithmic amplitude-frequency characteristics and phase-frequency characteristics of the speed control system when δ=0.02 and δ=0.05, as shown in image 3 and Figure 4 shown, based on image 3 and Figure 4 From the open-loop logarithmic frequency characteristics shown, find the shear frequency ω of the sp...

specific Embodiment approach 3

[0043] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the low-frequency and high-frequency frequency deviation signal Δf determined in step 2 after Δf passes through the frequency divider 1 (s) and Δf 2 (s) The specific process is:

[0044]

[0045]

[0046]

[0047]

[0048] The Δf(s) is the frequency deviation signal Δf in the feedback channel of the speed control system.

[0049] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com