Method of producing enteric soft capsule

A technology of enteric-coated soft capsules and enteric-coated capsules, applied in the field of preparation of enteric-coated soft capsules, can solve problems such as poor adhesion and poor formability, and achieve the effect of preventing bad smell and aftertaste and excellent preparation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the enteric-coated soft capsule of the present invention is not particularly limited, and is a preparation method of an enteric-coated soft capsule comprising the following steps: (a) configuring a low-methoxy fruit containing gelatin and a degree of amidation of 5-25% Enteric-coated capsule shell liquid of glue, and (b) using the enteric-coated capsule shell liquid prepared in step (a) to encapsulate the capsule content by die-cutting method. Enteric property refers to the property of dissolving in the intestine without being dissolved in the stomach.

[0025] The gelatin in the present invention is not particularly limited, and includes gelatin with a freezing strength of 160-300 Bloom, preferably 200-300 Bloom. In addition, two or more gelatins with different freezing strengths can be mixed and used. For example, two kinds of gelatins with freezing strengths of 200 Bloom and 300 Bloom can be mixed to adjust the freezing strength.

[0026] A...

Embodiment 1

[0036] [Disintegration experiment]

[0037] (Preparation of Soft Capsules)

[0038] Disperse 24 mass parts of pectin (DE30, DA17) in 30 mass parts of glycerin, dissolve in warm water (80°C), and further add 60 mass parts of gelatin (300Bloom) and 16 mass parts of gelatin (200Bloom) at 70 °C, filtered through a 100-mesh sieve (0.15 mm in sieve opening), and defoaming under reduced pressure to prepare the capsule shell liquid of the present invention. Furthermore, 30 parts by mass of glycerin was dissolved in warm water at 80°C, and 100 parts by mass of gelatin (200 Bloom) was further added to dissolve at 70°C, filtered through a 100-mesh sieve (mesh opening: 0.15mm) and defoamed under reduced pressure , to prepare the control coating solution. Each capsule shell liquid has fluidity at 60°C, and a rotating device can be used for all of them.

[0039] Then, adopt the rotary mode soft capsule preparation device (manufactured by Fuji Capsule Co., Ltd.), 250mg capsule content (fi...

Embodiment 2

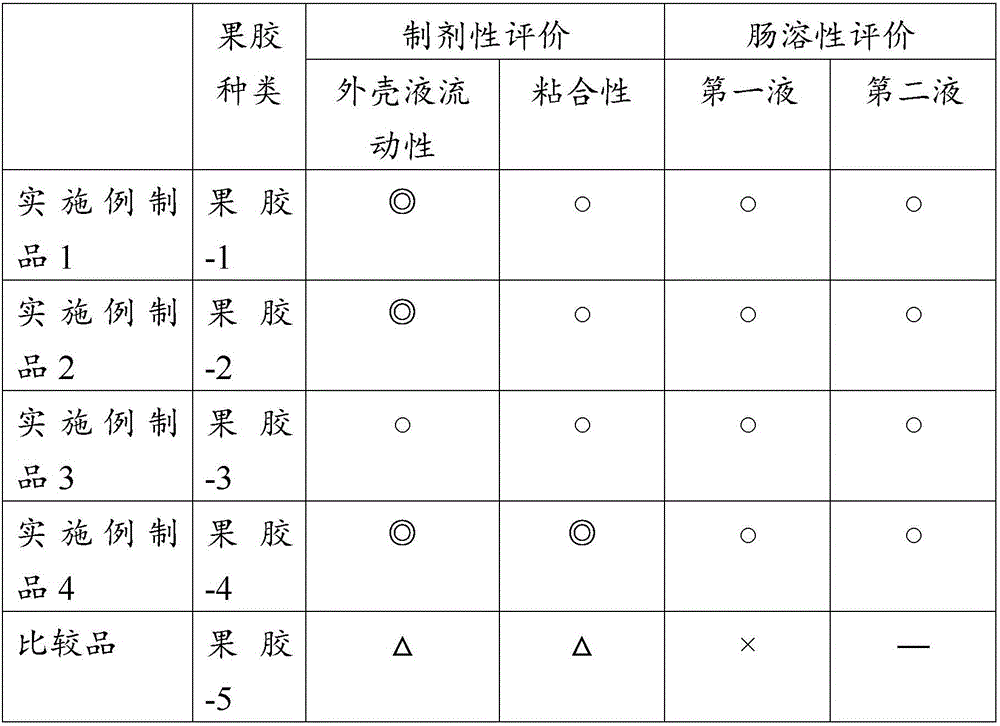

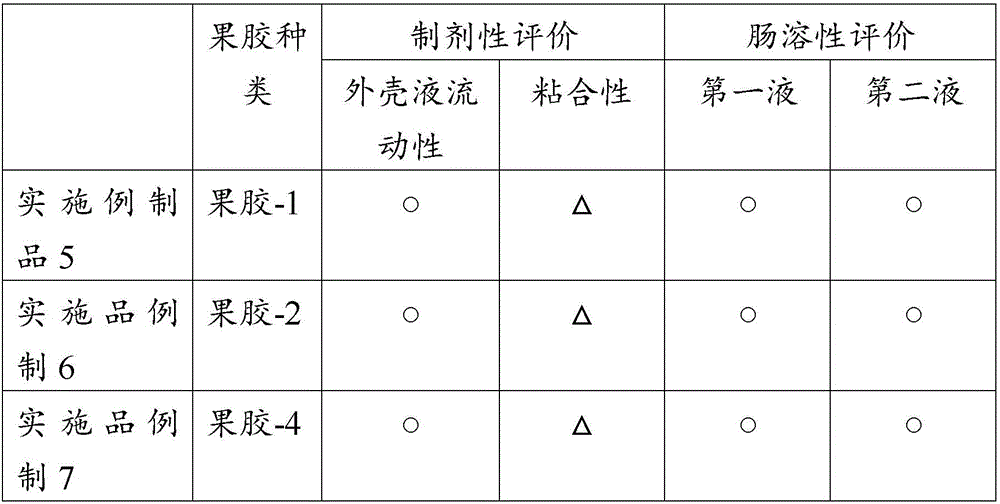

[0043] Formulation and enteric properties test 1

[0044] (Preparation of Soft Capsules)

[0045] 31.5 parts by mass of pectin shown in the following Table 1 were dispersed in 40 parts by mass of glycerin, dissolved in warm water (80° C.), and 79 parts by mass of gelatin (300 Bloom) and 21 parts by mass of gelatin (200 Bloom) were further added. Dissolve at 70° C., filter through a 60-mesh sieve (0.25 mm in sieve opening), and defoam under reduced pressure to prepare the capsule shell liquid. In the table, DE represents the degree of esterification (%) of each pectin, and DA represents the degree of amidation (%) of each pectin.

[0046] Table 1

[0047] Pectin type DE DA pectin-1 31-38 12-18 pectin-2 26-34 16-19 pectin-3 30-35 6-12 pectin-4 22-27 20-23 Pectin-5 33-38 0

[0048] Then, using a flat-plate soft capsule preparation device (manufactured by Fuji Capsule Co., Ltd.), medium-chain fatty acid triglycerides (MCT: coc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com