Method for producing a part of a household appliance and a part of a household appliance

A technology for household appliances and components, which is applied in the field of production of household appliance components, can solve problems such as excessive foam formation, and achieve the effects of reducing scrap rate, tight marking, hardness and density improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the figures, identical or functionally identical elements have the same reference signs.

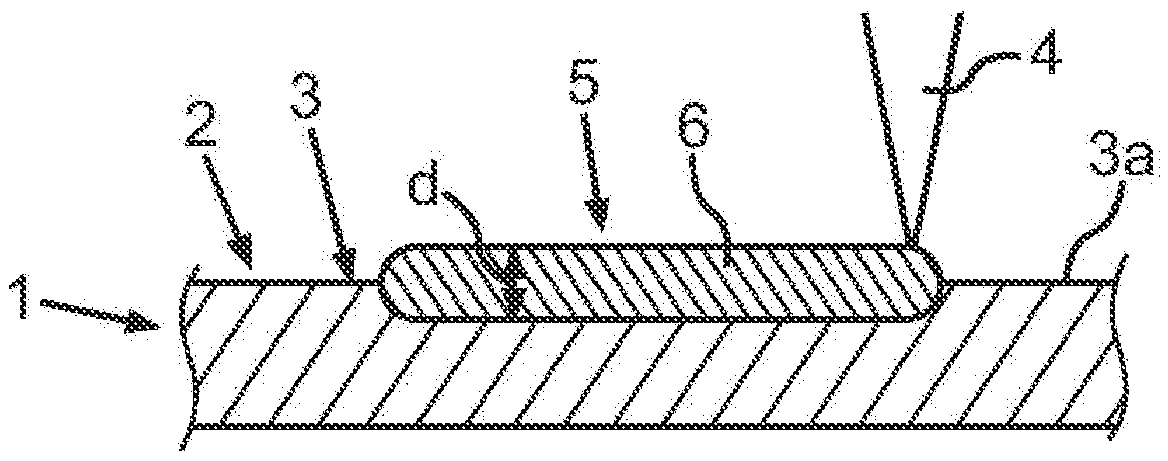

[0030] figure 1 In , a domestic appliance part 1 is shown in a sectional view, which may be, for example, a control panel. The household appliance part 1 comprises a base body or base 2 which is made at least partially, in this embodiment preferably completely, of plastic. On the top side 3 of the base 2 a marking 5 is produced by means of a laser 4 . In this case, the laser beam 4 melts the plastic material with its laser beam, whereby a plastic foam region 6 is produced which protrudes to the top relative to the surface 3 a in a convex manner. In this way, the marking 5 stands out visually in contrast to the plastic material which has not been treated by the laser 4 .

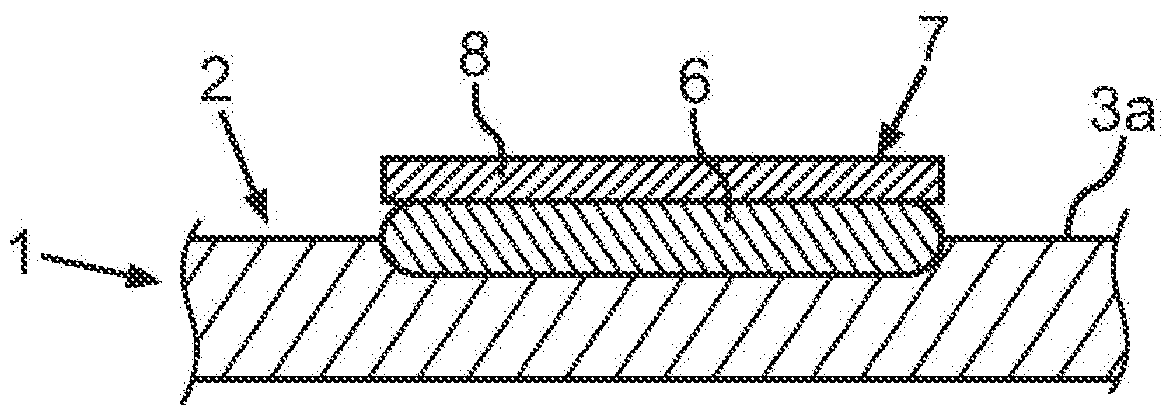

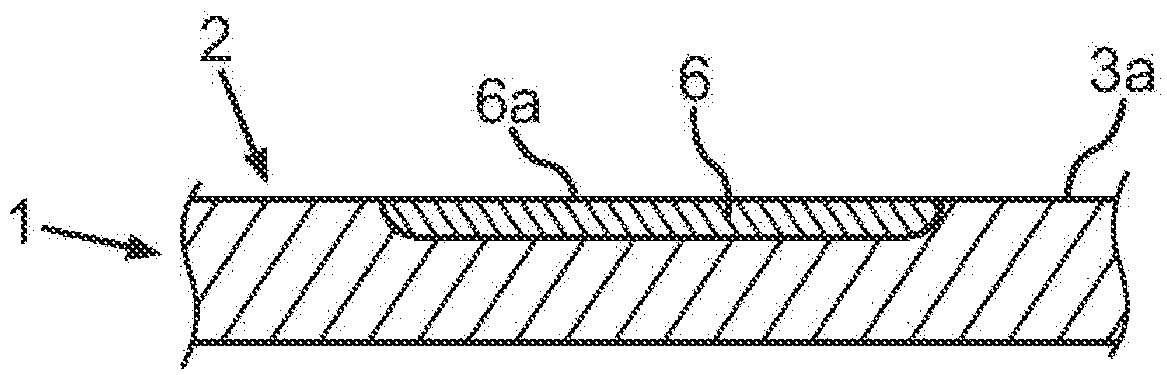

[0031] Then, in a subsequent step, after the creation of this plastic foam region 6 , the plastic foam region 6 is compressed and thus increased in its density. this is in figure 2 , wherein a compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com