Brake pressure modulator of an electronic braking system of a utility vehicle

A commercial vehicle, brake pressure technology, applied in the direction of brake control systems, brake safety systems, brakes, etc., can solve the problems of large structural space requirements and production costs, and achieve the goals of reducing construction costs, cost advantages, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

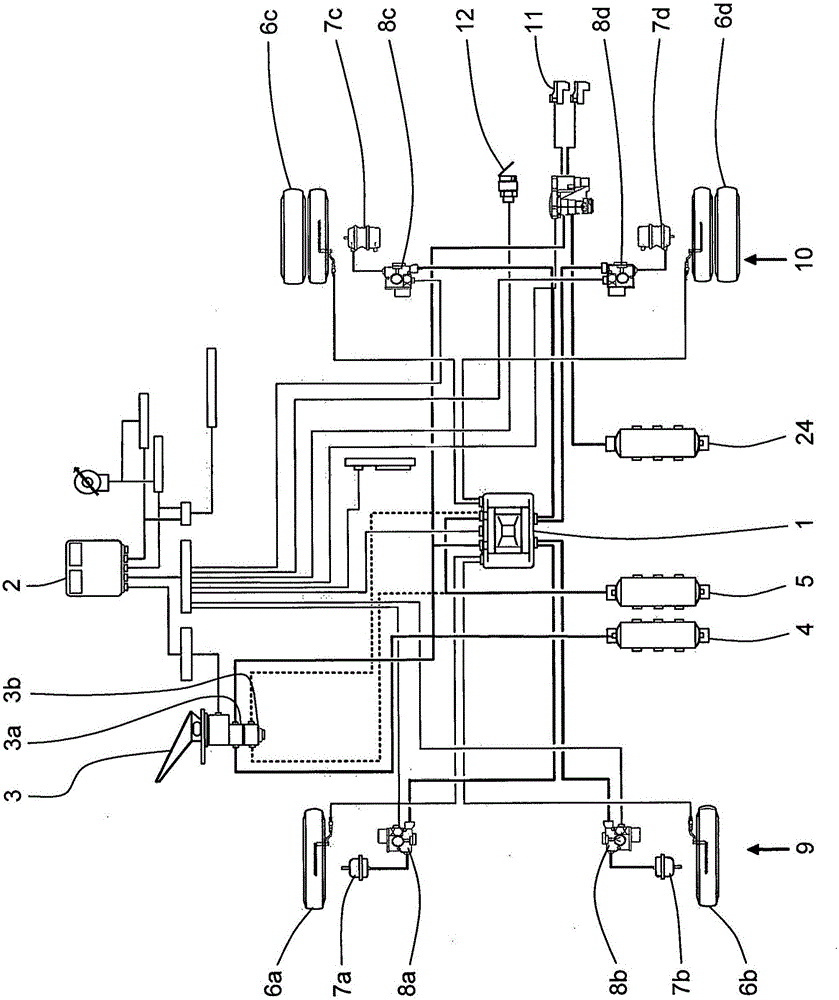

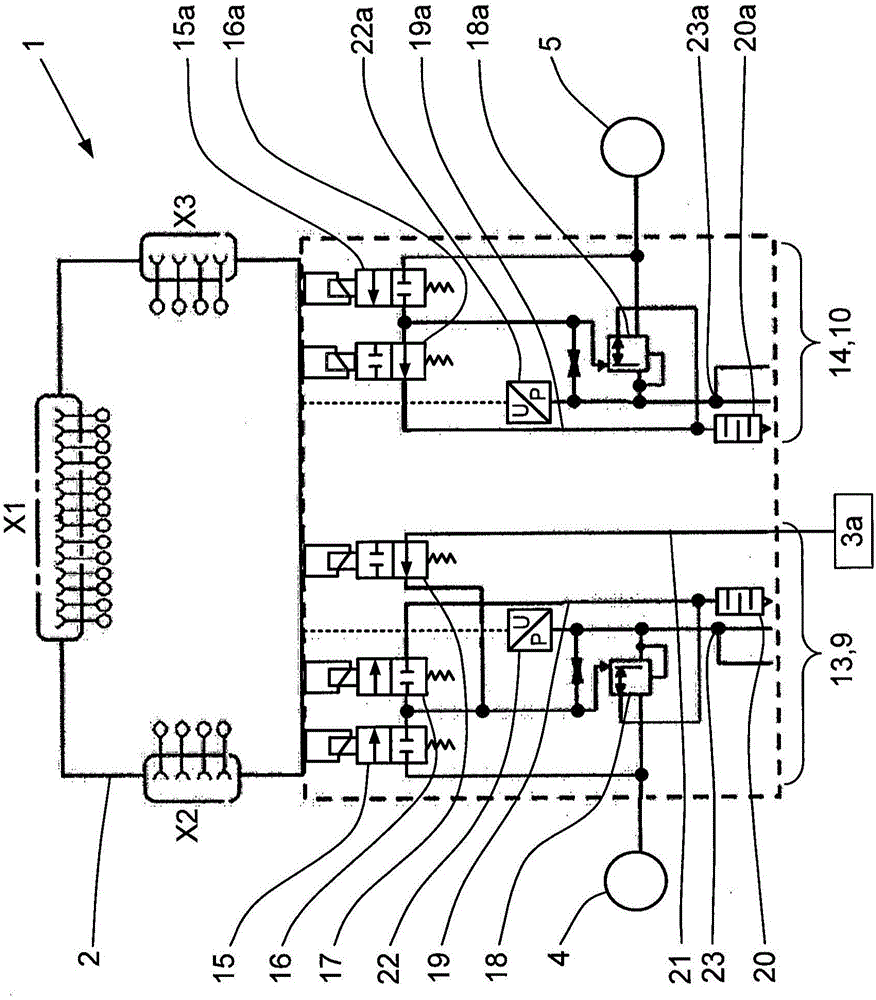

[0027] exist figure 1 In order to distinguish the pneumatic wiring and electrical wiring of components, the pneumatic connection is made with a larger line width than the electrical wiring.

[0028] figure 1 The brake system shown in has a brake pressure modulator 1 designed as a structural unit in which the hydraulic control components for the control of the two brake circuits 9 , 10 are combined. Also belonging to the brake system are the control electronics 2, the service brake parameter transmitter 3 with the first brake parameter transmitter valve 3a and optionally the second brake parameter transmitter valve 3b, the first compressed air Storage container 4 and second compressed air storage container 5, as well as a respective wheel brake 7a, 7b and a respective wheel brake modulator 8a, 8b for a wheel 6a, 6b of the front axle brake circuit 9, and a respective wheel brake modulator 8a, 8b for Each of the wheels 6a, 6b of the rear axle brake circuit 10 has a wheel brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com