Adhesive tape, article, motor, and method for producing article

A manufacturing method and motor technology, applied in the direction of chemical instruments and methods, adhesives, layered products, etc., can solve the problem that the second adhesive layer cannot show sufficient adhesive force on the adherend, and achieve excellent adhesive strength, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

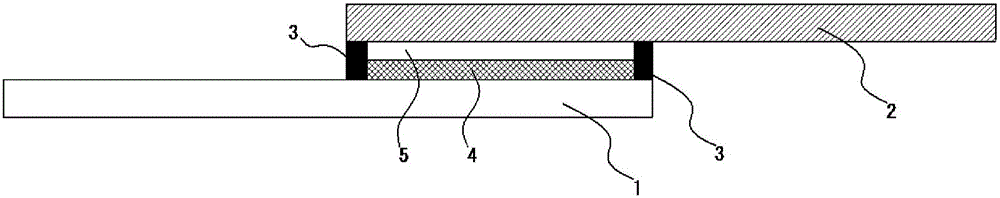

Image

Examples

preparation example 1

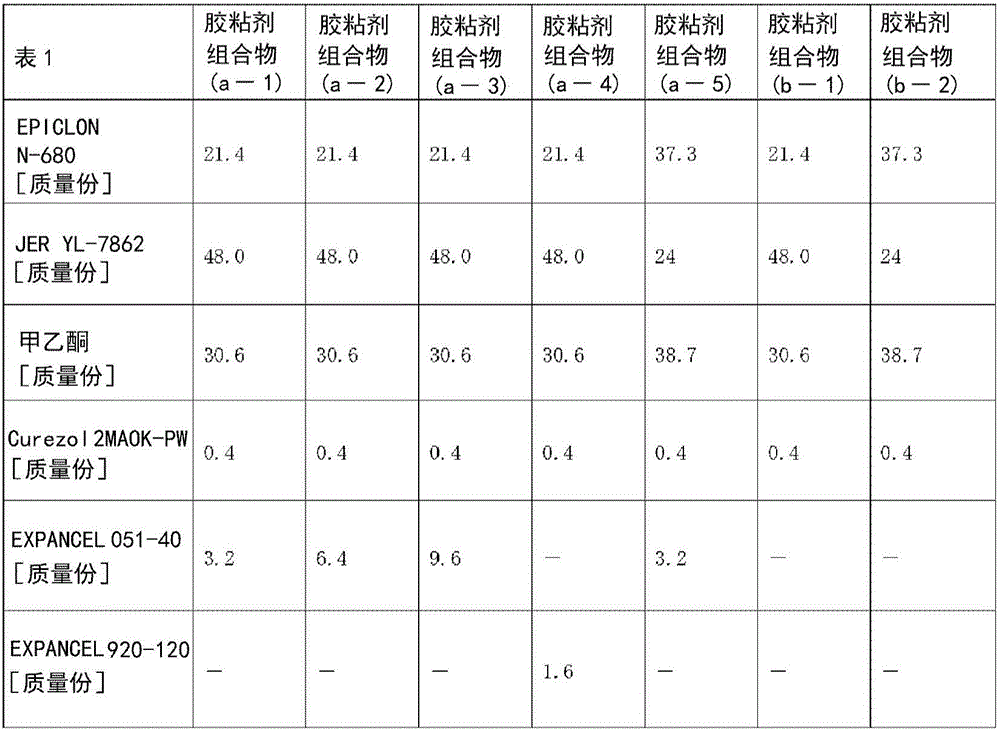

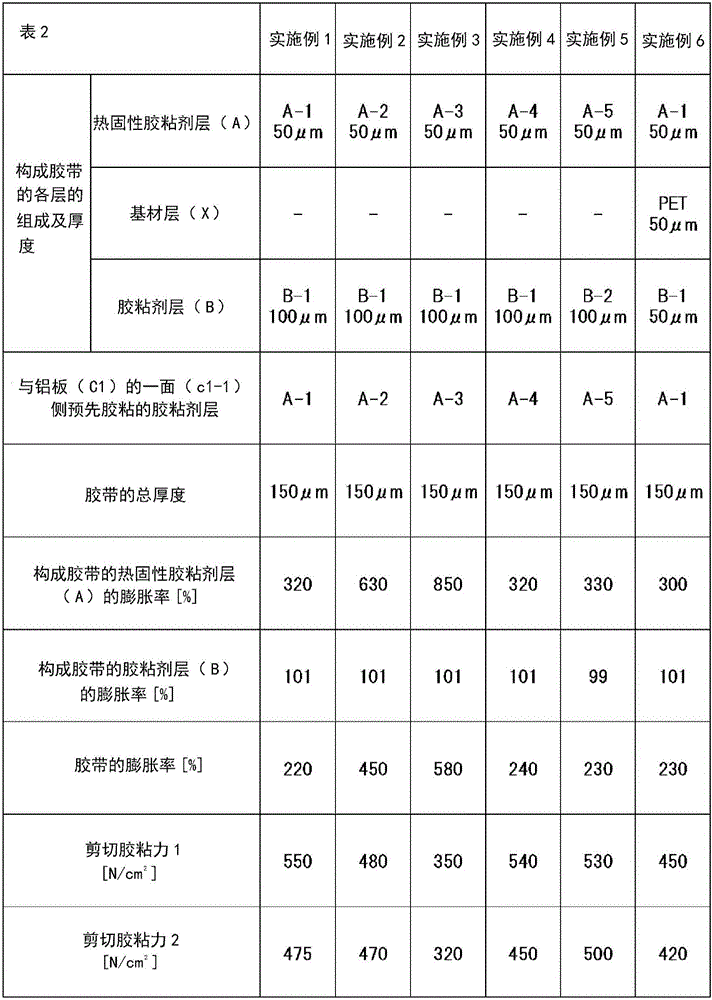

[0088]

[0089] 21.4 parts by mass of EPICLON N-680 (cresol novolac type epoxy resin solution manufactured by DIC Corporation, epoxy equivalent 215 g / eq, non-volatile content 75% by mass) and "JER YL-7862" (Mitsubishi Chemical Corporation After mixing 48 parts by mass of bisphenol A type epoxy resin solution manufactured by the company, epoxy equivalent 3748g / eq, 50% by mass of non-volatile components, 30.6 parts by mass of methyl ethyl ketone was mixed to obtain epoxy resin with 40% by mass of non-volatile components Resin composition (1).

[0090] Then, with respect to 100 parts by mass of the epoxy resin composition (1), EXPANCEL051-40 (manufactured by Japan Fillite Co., Ltd., heat-expandable microcapsules, initial particle size 12 μm, expansion start temperature 110° C., 130 The volume expansion rate at ° C is 7 times) 3.2 parts by mass, Curezol 2MAOK-PW (manufactured by Shikoku Chemicals Co., Ltd., imidazole-based curing accelerator) 0.4 parts by mass as a curing agent,...

preparation example 2

[0092]

[0093] Except that the amount of EXPANCEL 051-40 (manufactured by Japan Fillite Co., Ltd., heat-expandable microcapsules, initial particle size 12 μm, expansion start temperature 110°C, volume expansion rate 7 times at 130°C) was changed from 3.2 parts by mass Except that it was 6.4 parts by mass, an adhesive composition (a-2) was obtained by the method similar to Preparation Example 1.

preparation example 3

[0095]

[0096] Except that the amount of EXPANCEL 051-40 (manufactured by Japan Fillite Co., Ltd., heat-expandable microcapsules, initial particle size 12 μm, expansion start temperature 110°C, volume expansion rate 7 times at 130°C) was changed from 3.2 parts by mass Except that it was 9.6 parts by mass, an adhesive composition (a-3) was obtained by the method similar to Preparation Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com