PC-ABS alloy for thin-wall product and preparation method of alloy

A technology for PC-ABS and thin-walled products is applied in the field of PC-ABS alloy and its preparation, which can solve the problems of poor welding strength, easy occurrence of welding marks, and difficulty in punching at the welding place, and achieves good welding strength, not easy to break, Die smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

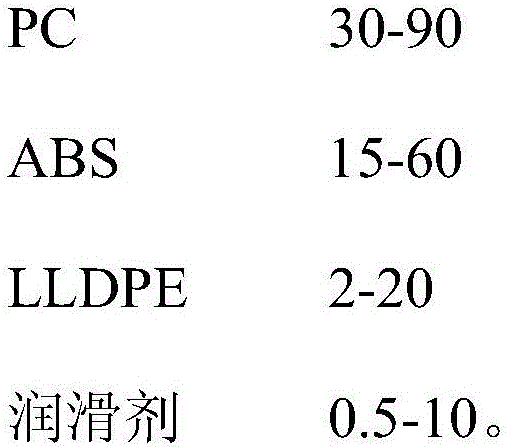

[0040] A PC-ABS alloy, in parts by weight, comprising the following components:

[0041]

[0042] The antioxidant uses hindered phenolic antioxidant 1010, that is, tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, and the lubricant uses fatty acid ester pentaerythritol hard Fatty acid esters (PETS).

[0043] The PC-ABS alloy is prepared by using the preparation method of the present invention. The results of testing its performance data are as follows:

[0044] Melt index (260°C / 5KG): 19g / 10min, tensile strength: 56Pa, elongation: 117%, impact strength: 655J / m.

Embodiment 2

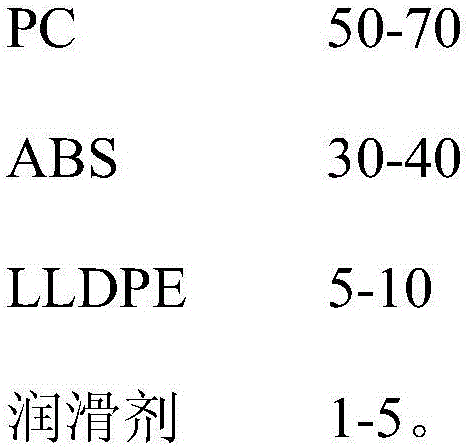

[0046] A PC-ABS alloy, in parts by weight, comprising the following components:

[0047]

[0048] The antioxidant uses hindered phenolic antioxidant 1010, that is, tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol, and the lubricant uses fatty acid ester pentaerythritol hard Fatty acid esters (PETS).

[0049] The PC-ABS alloy is prepared by using the preparation method of the present invention. The results of testing its performance data are as follows:

[0050] Melt index (260°C / 5KG): 30g / 10min, tensile strength: 62Pa, elongation: 139%, impact strength: 689J / m.

Embodiment 3

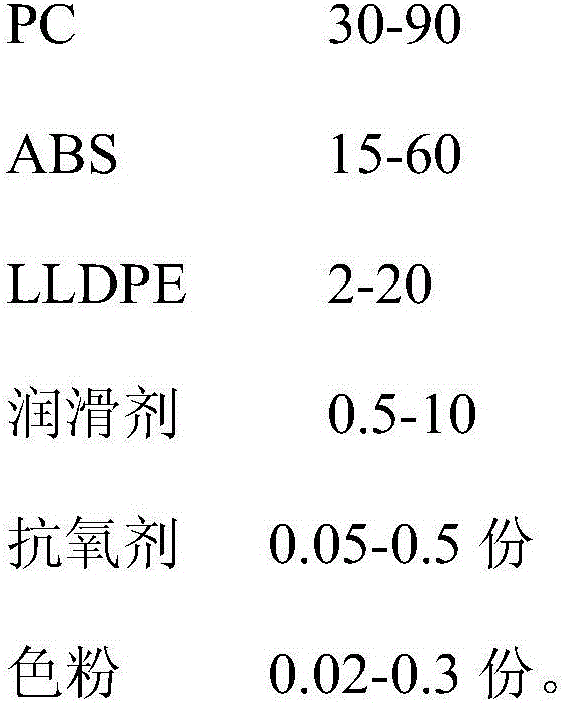

[0052] A PC-ABS alloy, in parts by weight, comprises the following components:

[0053]

[0054]

[0055] The antioxidant uses hindered phenolic antioxidant 168, that is, tris[2,4-di-tert-butylphenyl] phosphite, and the lubricant uses oxidized polyethylene wax.

[0056] The PC-ABS alloy is prepared by using the preparation method of the present invention. The results of testing its performance data are as follows:

[0057] Melt index (260°C / 5KG): 21g / 10min, tensile strength: 60Pa, elongation: 126%, impact strength: 720J / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com