Full-color reflective thermal-insulation coating system for buildings, and preparation method thereof

A reflective heat-insulating coating, a technology for construction, applied in the field of coatings, can solve the problems of difficulty in producing bright colors, expensive cold paints, dark colors of cold paints, etc., achieve excellent energy-saving effects, satisfy decorative effects, and bright colors Department of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing a medium-brightness blue heat-insulating reflective coating system, the method comprising the following steps:

[0047] Thermal insulation coating primer

[0048] Component name Parts by weight 7607 Styrene Acrylic Emulsion35.0 Distilled water29.7 Titanium Dioxide20.0 Ceramic beads7.0 5040 dispersant3.0 NXZ defoamer0.3 PE100 wetting agent0.3 AMP-950.2 LXE fungicide0.3 Propylene Glycol2.0 Dodecyl alcohol1.7 Thickener0.5

[0049] Thermal insulation coating

[0050]

[0051]

[0052] The coating preparation process:

[0053] (1) Preparation of primer:

[0054] After putting 29.7 parts of distilled water into the stirring tank, add 3.0 parts of 5040 dispersant, 0.3 parts of LXE fungicide, 0.3 parts of PE100 wetting agent, 0.3 parts of NXZ defoamer, 0.2 parts of AMP-95, 2.0 parts of propylene glycol, and stir well; Add 20.0 parts of titanium dioxide pigment and 7.0 parts of ceramic microbeads successively, and stir for 1-2 hours at 2000-3000RPM r...

Embodiment 2

[0058] A method for preparing low-brightness gray heat-insulating reflective paint, the method comprising the following steps:

[0059] Thermal insulation coating primer

[0060] Component name Parts by weight 7607 Styrene Acrylic Emulsion35.3 Distilled water28.7 Titanium Dioxide16.0 Insulation powder11.0 5040 dispersant4.0 NXZ defoamer0.3 PE100 wetting agent0.3 LXE fungicide0.3 AMP-950.2 Propylene Glycol2.0 Dodecyl alcohol1.7 Thickener0.5

[0061] Thermal insulation coating

[0062]

[0063]

[0064] The coating preparation process:

[0065] (1) Preparation of primer:

[0066] First put 28.,7 parts of distilled water into the stirring tank, add 4.0 parts of 5040 dispersant, 0.3 parts of LXE fungicide, 0.3 parts of PE100 wetting agent, 0.3 parts of NXZ defoamer, 0.2 parts of AMP-95, 2.0 parts of propylene glycol, Stir uniformly; add 16.0 parts of titanium dioxide pigment and 11.0 parts of thermal insulation powder in turn, stir for 1-2 hours at 2000-3000RPM rotation spee...

Embodiment 3

[0070] A method for preparing high-brightness yellow heat-insulating reflective paint, the method comprising the following steps:

[0071] Thermal insulation coating primer

[0072]

[0073]

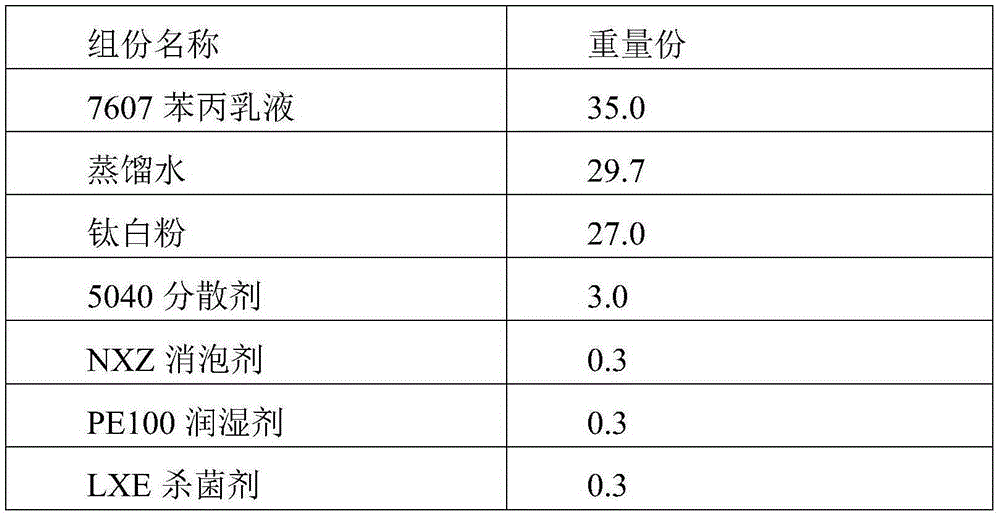

[0074] Thermal insulation coating

[0075] Component name Parts by weight 7016G pure acrylic emulsion42.0 Distilled water16.7 5040 dispersant4.0 PE100 wetting agent0.3 NXZ defoamer0.5 LXE fungicide0.3 AMP-950.2 Propylene Glycol2.0 Titanium Dioxide6.0 Titanium Chrome Yellow Pigment1.5 Thickener1.0 Ceramic powder5.5 Insulation powder9.0 Functional titanium dioxide8.0 Dodecyl alcohol3.0

[0076] The coating preparation process:

[0077] (1) Preparation of primer:

[0078] First put 29.7 parts of distilled water into the stirring tank, add 3.0 parts of 5040 dispersant, 0.3 parts of LXE fungicide, 0.3 parts of PE100 wetting agent, 0.3 parts of NXZ defoamer, 0.2 parts of AMP-95, 2.0 parts of propylene glycol, and stir well; Add 27.0 parts of titanium dioxide pigment successively, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com