Blind rivet element

A blind rivet, component technology, applied in the direction of rivets, screws, connecting components, etc., can solve problems such as small electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

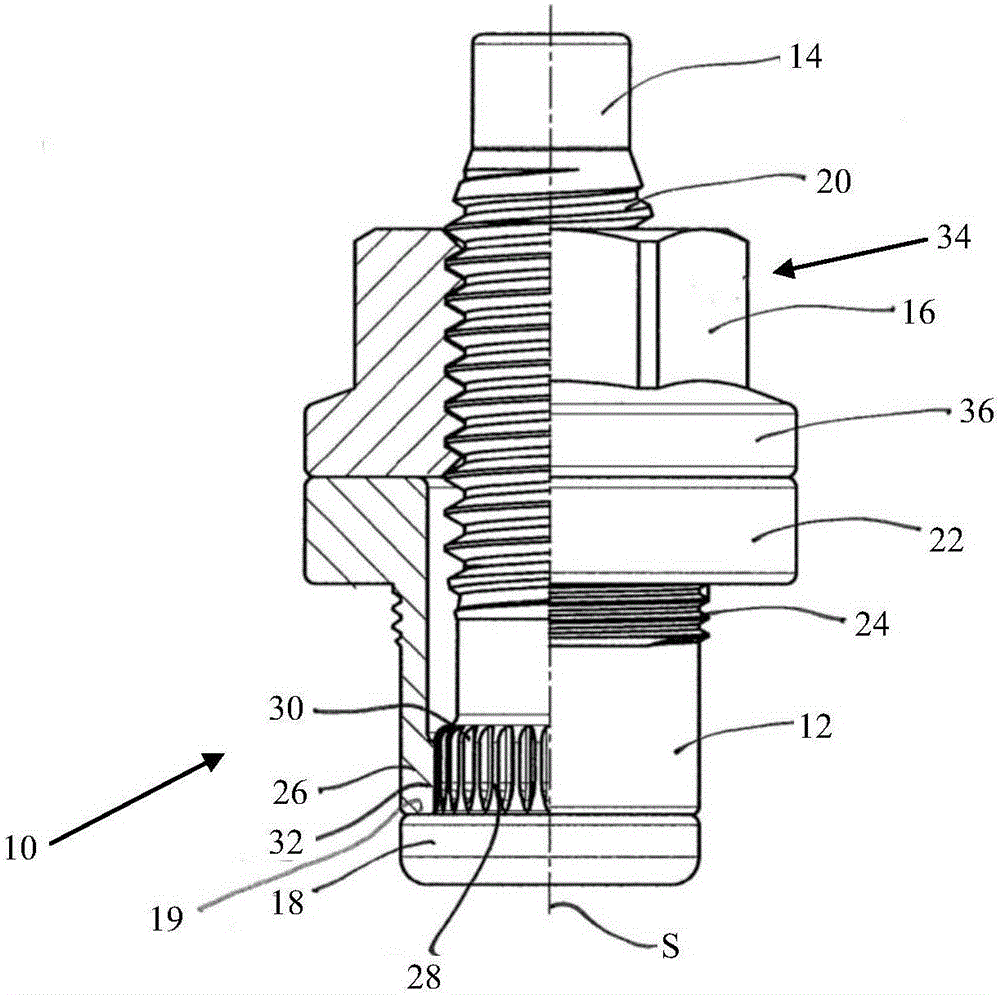

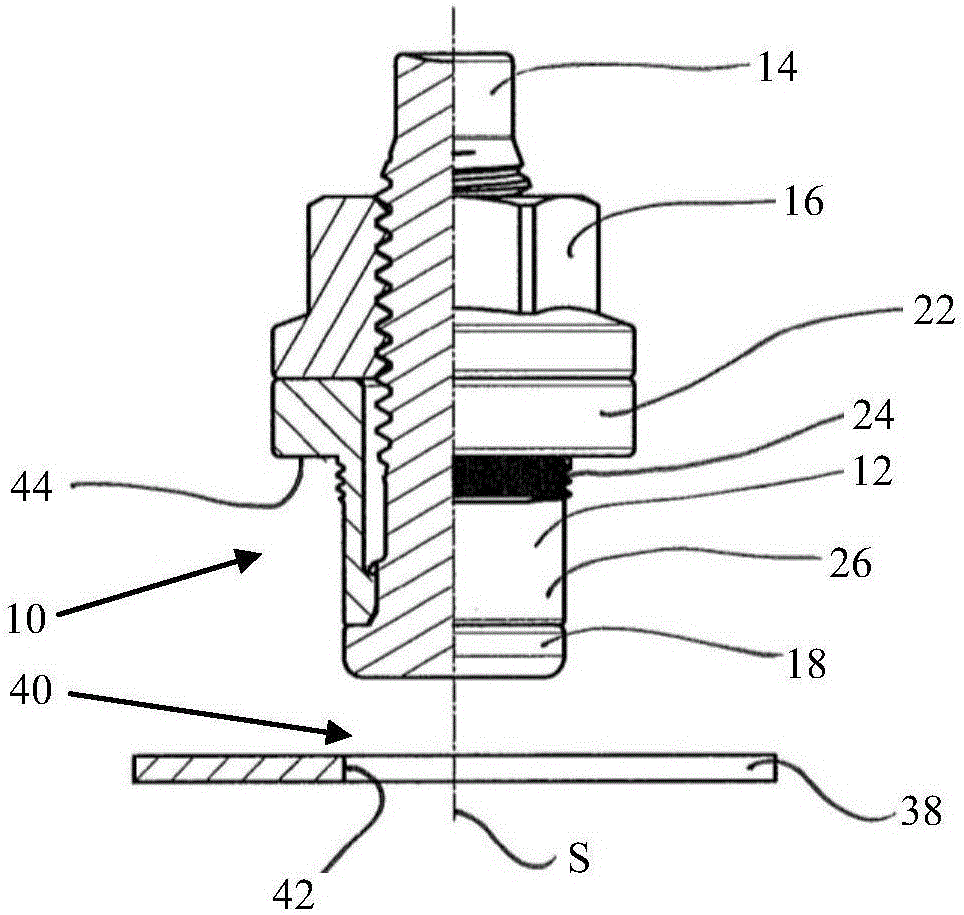

[0056] figure 1 A rotationally symmetrical blind rivet element 10 is shown, comprising a sleeve body 12 , a bolt 14 passing through the sleeve body 12 and a nut 16 . The screw element 14 has a screw head 18 , on whose shoulder 19 the sleeve body 12 is seated. The bolt member 14 also has a thread 20 that cooperates with the internal thread of the nut 16 , that is, the nut 16 is screwed onto the bolt member 14 in the area of the thread 20 .

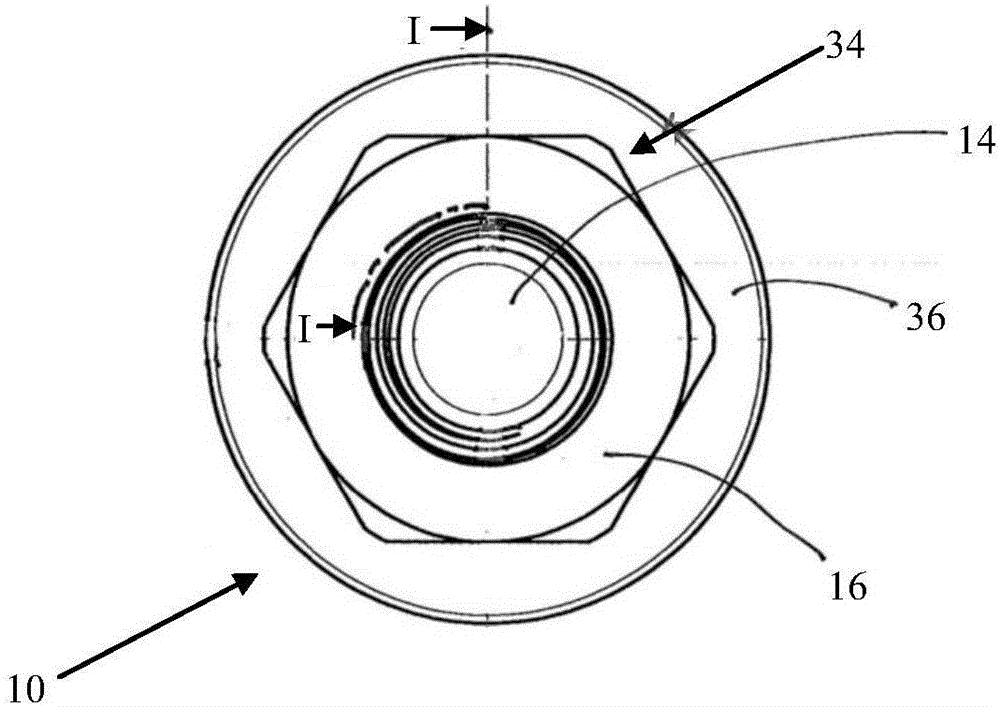

[0057] figure 1 The view of is divided into a left side sectional view and a right side side view with respect to the axis of symmetry S. With respect to the section plane I of the left sectional view at figure 2 shown in . At this point it should be noted that the sectional plane I extends partly straight through the sleeve body 12 and the nut 16 . The cutting plane I also extends along the outer periphery of the bolt member 14 in a curvilinear manner, so that the bolt member 14 is figure 1 Effectively shown as a side view in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com