Axial air-gap rotary electric machine

一种旋转电机、轴向间隙的技术,应用在带有静止电枢和旋转磁体的同步电动机、电气元件、机电装置等方向,能够解决成本增加、生产效率恶化、间隙尺寸减小等问题,达到成本降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

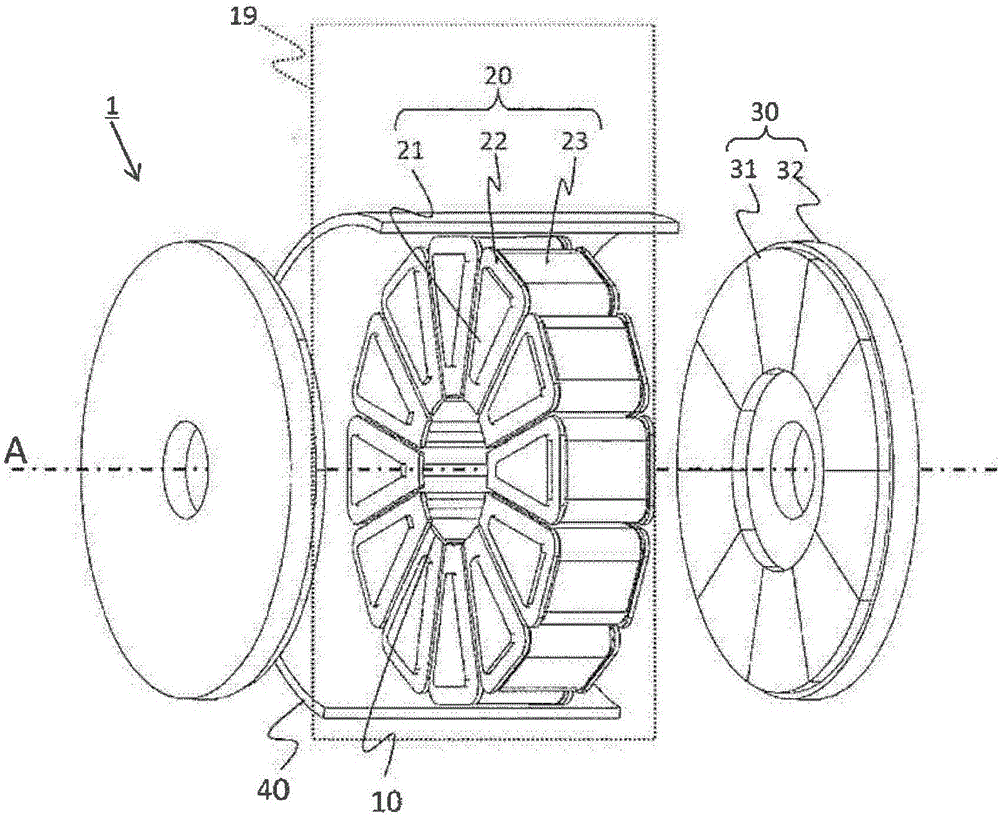

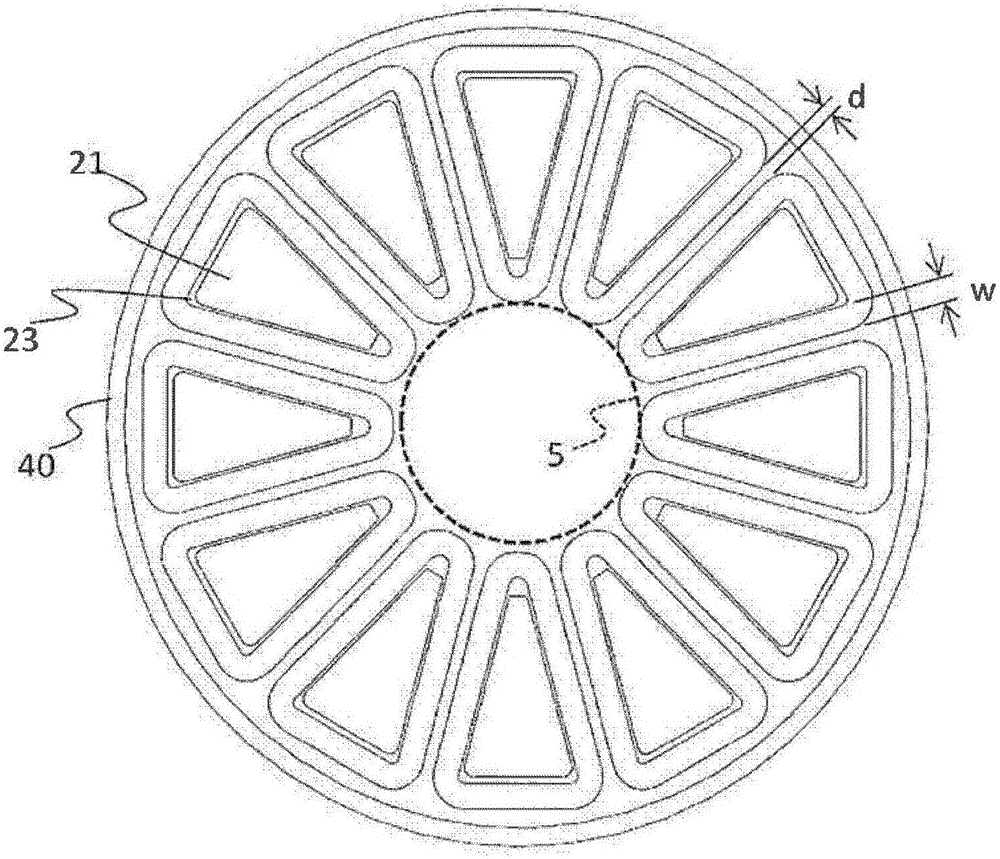

[0031] Hereinafter, the form for implementing this invention is demonstrated using drawing. figure 1 , schematically shows the armature structure of the dual-rotor axial gap permanent magnet synchronous motor 1 (hereinafter sometimes referred to as "motor 1") according to the first embodiment of the present invention.

[0032] The motor 1 includes an annular stator 19 along the inner periphery of a housing 40 and two disk-shaped rotors 30 arranged to sandwich the stator 19 in the axial direction of the rotating shaft. The end surface of the stator 19 and the circular plane of the rotor 30 face each other with a predetermined gap in the radial direction of the rotation axis. A rotating shaft (not shown) connected to the center of the rotor 19 penetrates through the gap of the inner cylinder formed at the center of the stator 20 and is connected to the rotor 19 disposed on the opposite side with the stator 20 interposed therebetween. Both ends of the rotary shaft are rotatably ...

no. 2 approach

[0057] One of the features of the motor 1 of the second embodiment is that the first region 10 of the first embodiment is used as a region for accommodating the connecting wires 51 drawn from the core members 20 .

[0058] Figure 7 It is a perspective view showing the stator 19 of the motor 1 . In addition, resin for molding the stator 19 is omitted for simplicity. In addition, for the same parts as those of the first embodiment, the same symbols are used and descriptions thereof are omitted.

[0059] The connection wire 51 drawn out from the magnetic core member 51 is arranged in the first region 10 formed on the one output shaft side. The connecting wires 51 are gathered to the magnetic core member 20 closest to the terminal box to form a connecting wire group 50 .

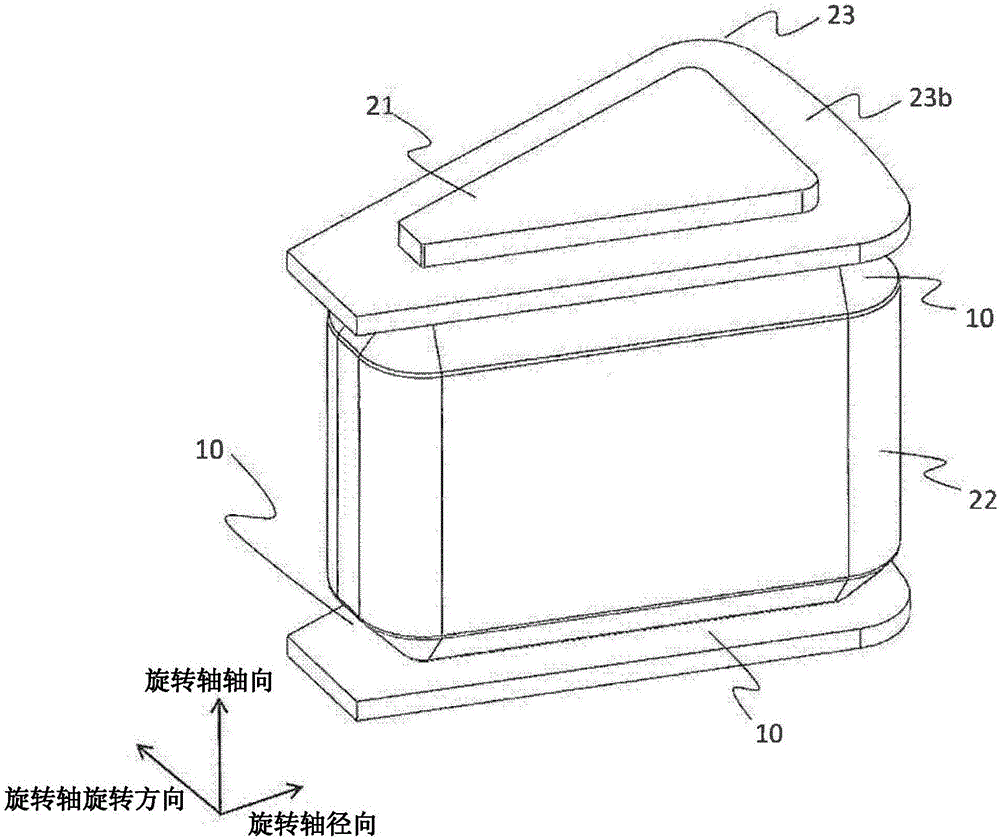

[0060] In the case where the coil 22 is wound around the entire area between the flange portions 23b, it is conceivable to place the connecting wires near the surface of the flange portion 23b on the rotor 3...

no. 3 approach

[0064] One of the features of the motor 1 of the third embodiment is that the first region 10 formed on the inner peripheral side of the casing 40 from the rotation axis direction is used as a wiring arrangement region.

[0065] Figure 8 It is a sectional perspective view showing the stator 19 of the third embodiment. In addition, for the same parts as those of the first embodiment, the same symbols are used and descriptions thereof are omitted.

[0066] The motor 1 of the third embodiment has a cylindrical first conductive member 61 on the rotation axis side of the stator 19 . The first conductive member 61 is formed of a thin plate bent into a cylindrical shape, and the rotation shaft penetrates through the inner cylinder side. The lead wire 62 is connected to a part of the outside of the first conductive member 61 . The lead wire 61 passes through the first region 10 formed on the inner peripheral side of the case 40 from the rotation axis, and the other end is electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com