Operation method of soybean sprout washing and peeling device

An operation method and technology of soybean sprouts are applied in the fields of vegetable or fruit peeling, food processing, food science, etc., which can solve problems such as difficulty in improving production efficiency, unreasonable structural design, and affecting normal production, and achieve simple structure and high effect. Ideal, the effect of reducing the cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

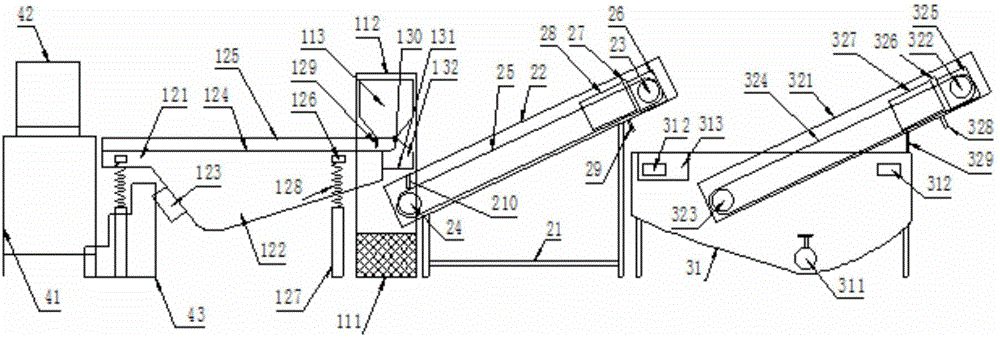

[0019] The feeding end of the vibrating dispersing equipment is provided with a dish-loading operation platform 41, and a bean sprout turnover box 42 is arranged above the vegetable-loading operating platform 41, and a peeling equipment is set between the discharge end of the vibrating dispersing equipment and the secondary cleaning and peeling equipment. A platform step 43 is set on one side of the feeding end of the dispersing equipment;

[0020]The structure of the vibration dispersing equipment is as follows: a gauze is arranged around the frame 111, an airtight bellows 112 is arranged above the frame 111, an air blowing mechanism is arranged in the airtight bellows 112, an airtight air cover 113 communicating with the airtight air box 112 is arranged on one side above the airtight air box 112, and the airtight air box 113 The cross-sectional structure is: the upper part of the inverted isosceles trapezoid is a rectangle, and the lower part of the inverted isosceles trapezo...

Embodiment 2

[0025] The specific operation method of the soybean sprouts entering the vibration dispersion equipment to remove bad beans is: before use, start the vibration motor 123, the vibration motor 123 drives the vibration dispersion bed 121 to vibrate, and the four columns 127 support the vibration dispersion bed 121 through the spring 128 , the vibrating dispersing bed 121 vibrates at a set vibration speed, and the airflow produced by the blower mechanism in the airtight bellows 112 passes through the airtight wind hood 113 and blows out from the air outlet to the fork 130, so that the soybean sprouts are put into the vibrating dispersing bed 121 for dispersion. On the platform 124, under the vibration effect of the vibrating dispersion bed 121, the soybean sprouts are dispersed on the dispersion platform 124 and then move towards the discharge end direction. Adjust the reserved gap between the material blocking plate 129 and the dispersion platform 124 according to production needs ...

Embodiment 3

[0027] The specific operation method of entering the primary peeling equipment for peeling is as follows: the soybean sprouts that remove bad beans enter the primary peeling conveyor belt 25 of the primary peeling equipment, and the primary peeling motor 28 controls the primary peeling motion by the primary peeling controller 26. The rotating speed of rotating shaft 23, adjust the rotating speed of primary peeling active rotating shaft 23 according to production needs, adjust the distance between rear baffle plate 210 and primary peeling conveyor belt 25 to avoid soybean sprouts from falling, and soybean sprouts are driven by primary peeling conveyor belt 25 Move from bottom to top, fall into the cleaning and cooling tank 31 of the secondary cleaning and peeling equipment, because the soybean sprouts belt has moisture content, the soybean sprouts skin sticks to the primary peeling conveyor belt 25 and continues to run with the primary peeling conveyor belt 25. Need to adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com