Pallet conveying system with positioning and deviation correction

A pallet conveying and deflection correction technology, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of unfixed pallet specifications, pallet skew, and unrecognizable pallet size, etc., so as to reduce the cost of warehouse use and improve Storage rate, effect of increasing product versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

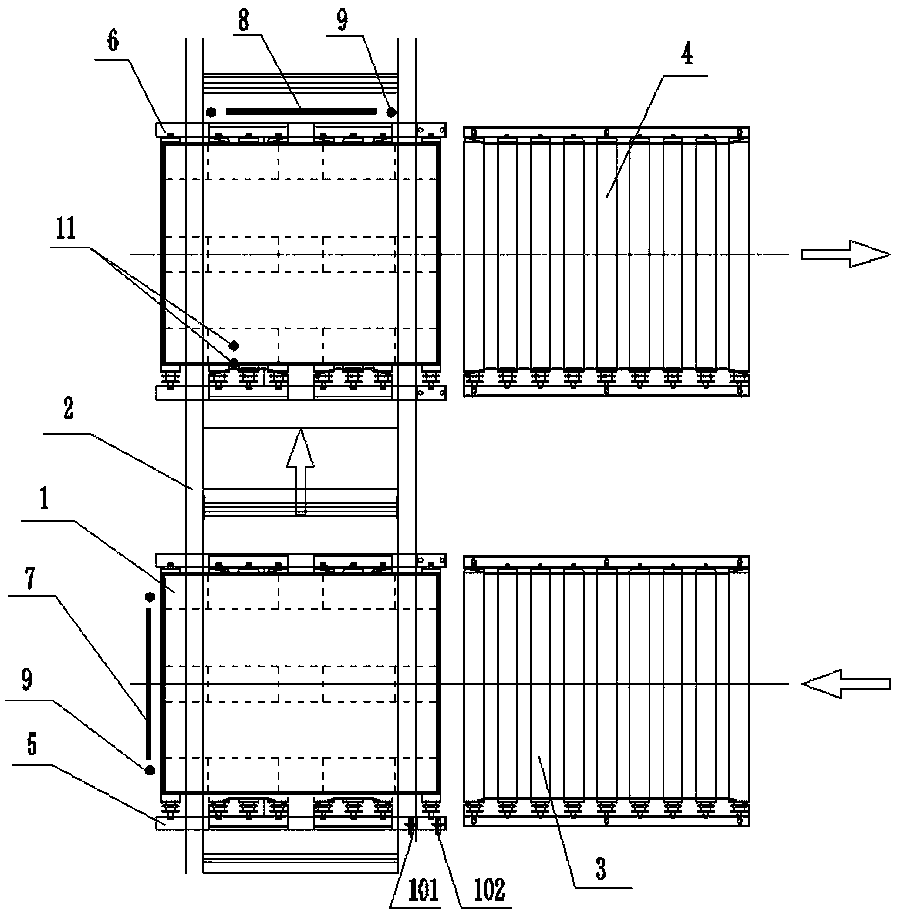

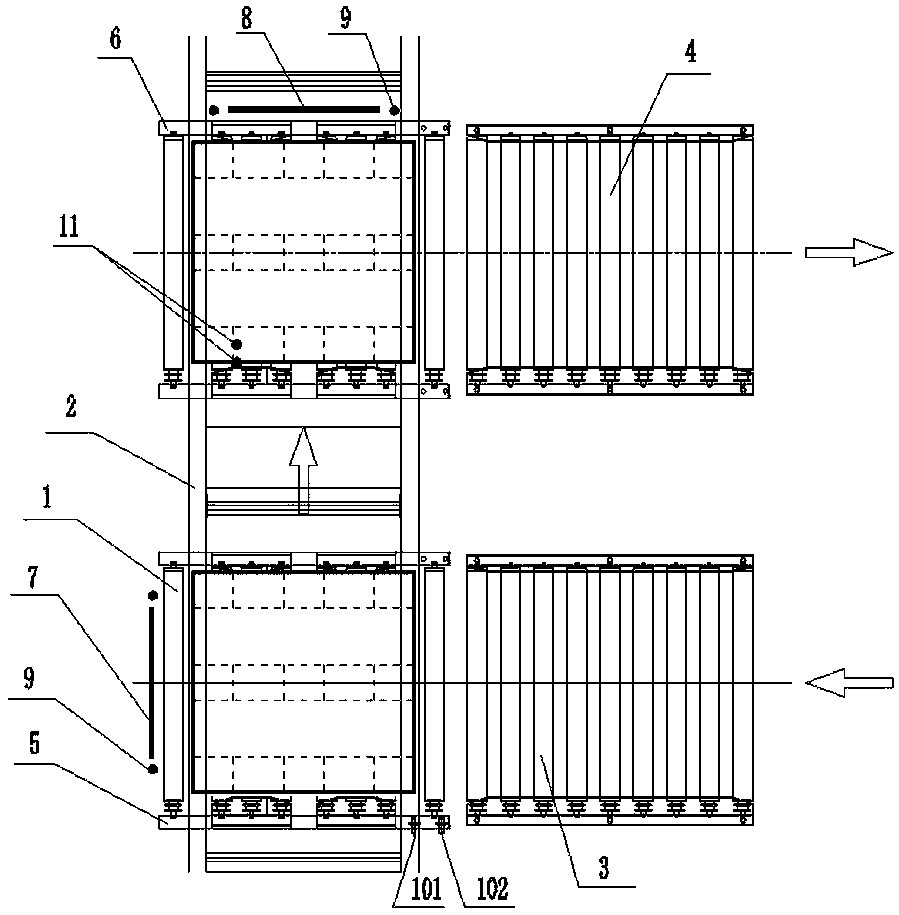

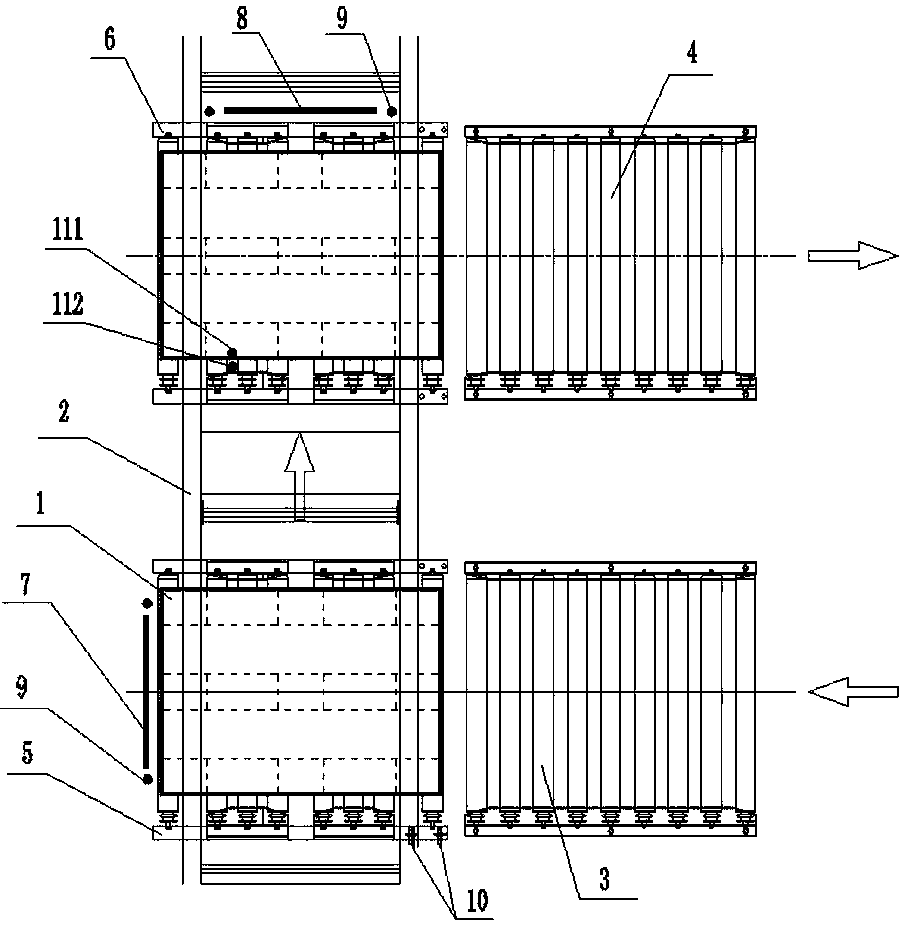

[0022] Such as Figure 1~Figure 4 As shown, the pallet conveying system that can be positioned and corrected in the present invention includes a pallet 1, a chain conveyor 2, a roller conveyor and an identification system, and the chain conveyor 2 and the roller conveyor are vertically distributed, so There are two roller conveyors, including an incoming roller conveyor 3 and an outgoing roller conveyor 4, the incoming roller conveyor 3 and the outgoing roller conveyor 4 are arranged in parallel, and the chain The intersection of the chain conveyor 2 and the incoming roller conveyor 3 is provided with a first lifting roller conveyor 5, and the intersection of the chain conveyor 2 and the delivery roller conveyor 4 is provided with a second lifting roller conveyor. 6. The pallet 1 is moved between the incoming roller conveyor 3 and the chain conveyor 2 through the first lifting roller machine 5, and the pallet 1 is moved between the chain conveyor 2 through the second lifting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com