pH value control device and method for chemical combination tank for EMD continuous leaching process

A control device and process technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of unstable control, product quality is greatly affected by human factors, prone to errors, etc., and achieves high degree of automation and reliability, human-machine interface Friendly, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

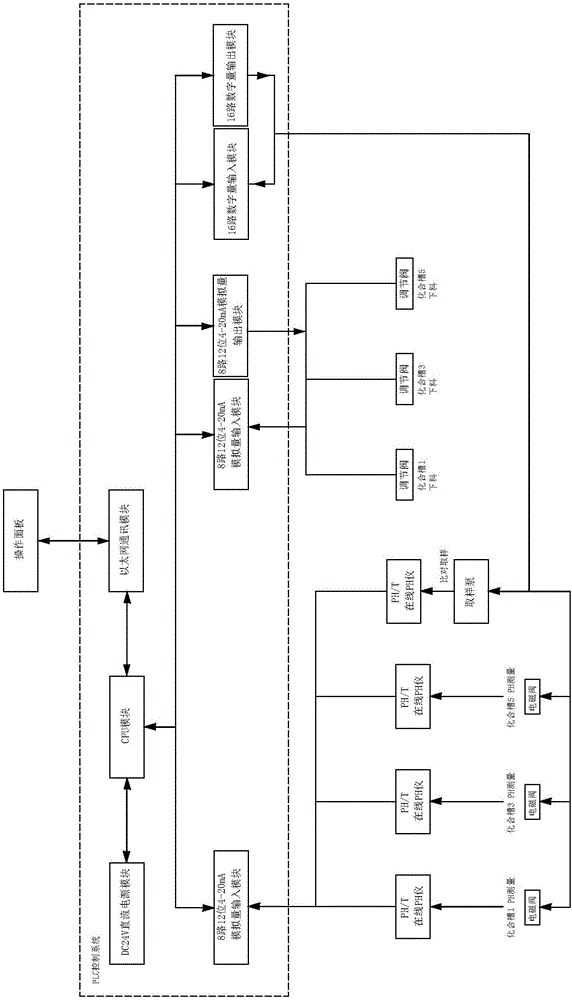

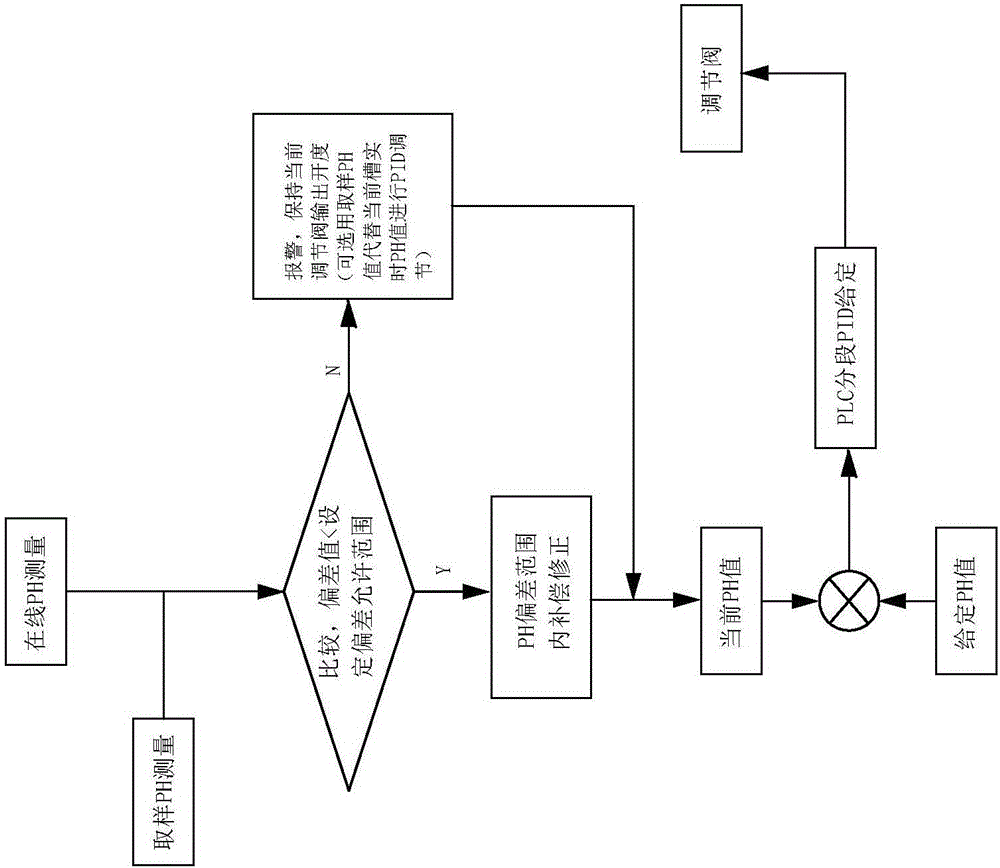

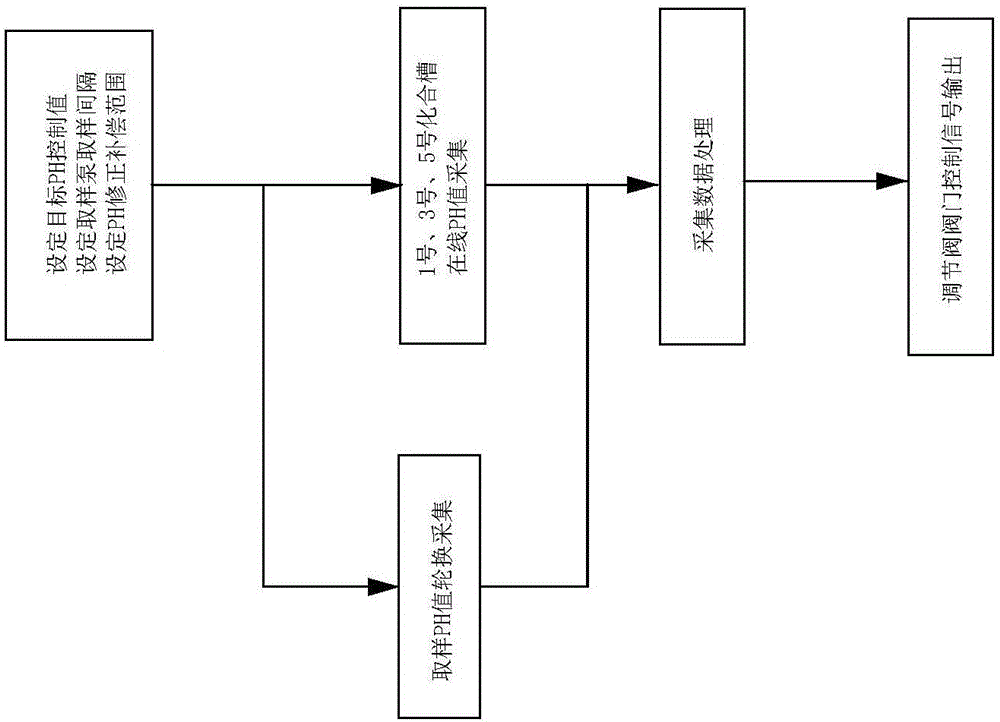

[0024] Such as figure 1 As shown, the pH value control device of the EMD continuous leaching process chemical combination tank of the present invention includes a PLC control system and an operation panel, and the PLC control system includes a CPU module and a DC24V DC power supply module, an Ethernet communication module, and an analog input module respectively connected to the CPU module. Module Ⅰ, analog input module Ⅱ, analog output module, digital input module, digital output module. The Ethernet communication module is connected to the operation panel, and the control device also includes four online pH meters, three solenoid valves, one sampling pump, and three regulating valves, one of which is set between No. 1 and No. 2 chemical combination tanks. In the overflow pipe, one online pH meter is set in the overflow pipe between No. 3 and No. 4 chemical combination tanks, one online pH meter is set in the overflow pipe between No. 5 and No. The input ends of the solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com