Piston ring suitable for automobile engine

An automobile engine and piston ring technology, applied in the field of piston rings, can solve the problems of carbon deposition, wear, poor sealing performance of piston rings, etc., and achieve the effects of reducing air leakage, prolonging service life, and avoiding carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

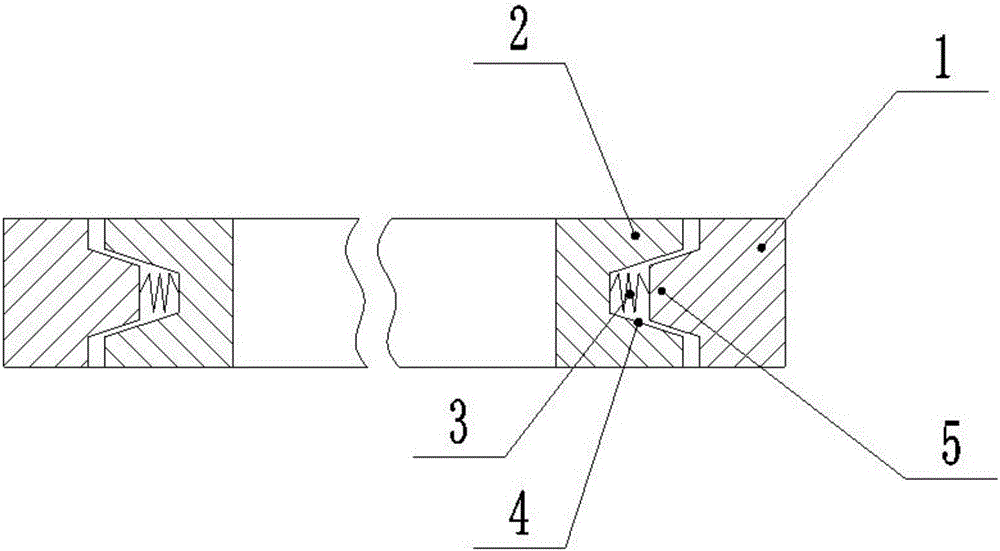

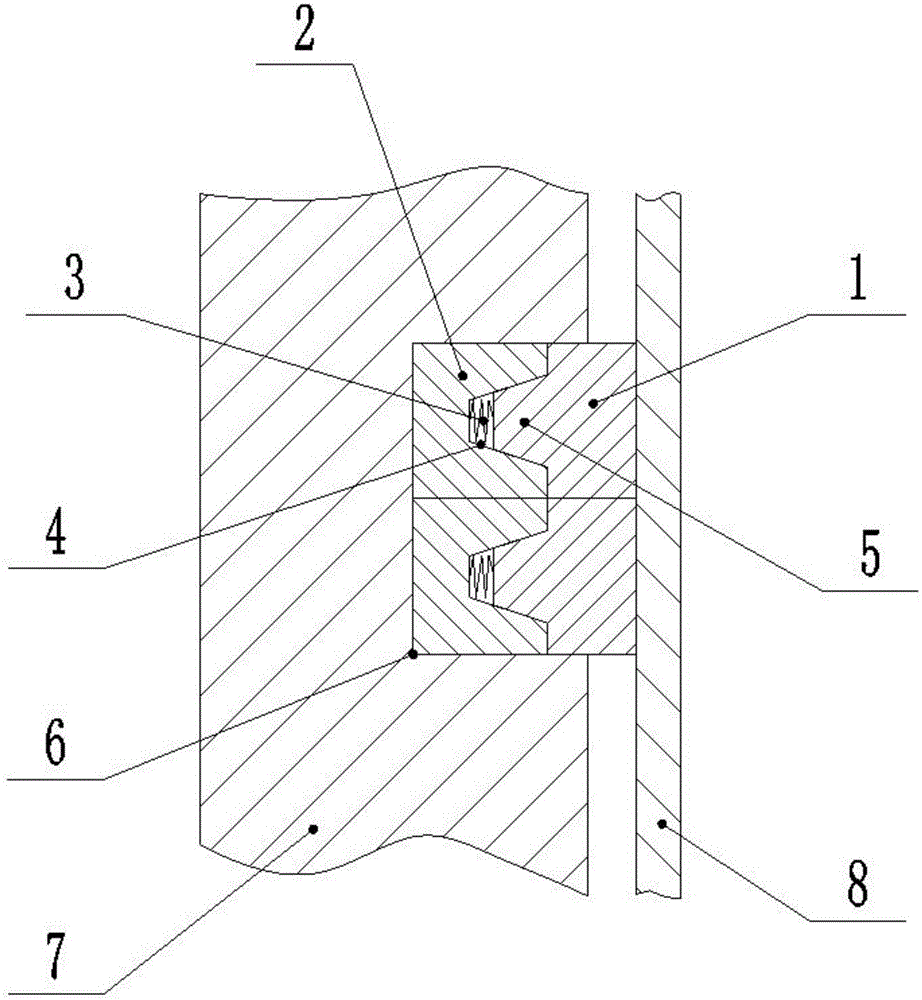

[0016] like figure 1 and figure 2 The shown piston ring suitable for an automobile engine includes a first ring 1 in an annular structure, and a second ring 2 nested in the first ring 1;

[0017] The outer peripheral surface of the second ring 2 is provided with an inwardly recessed trapezoidal groove 4, and the inner peripheral surface of the first ring 1 is provided with an outwardly protruding trapezoidal block 5, and the trapezoidal block 5 is nested in the trapezoidal groove 4 , A spring 3 is installed between the trapezoidal block 5 and the trapezoidal groove 4, one end of the spring 3 is connected to the trapezoidal block 5, and the other end of the spring 3 is connected to the trapezoidal groove 4.

[0018] Both the trapezoidal block 5 and the trapezoidal groove 4 are arranged in an annular shape.

[0019] The angle between the two slopes of the trapezoidal block 5 is 61 degrees to 64 degrees, and the angle between the two slopes of the trapezoidal groove 4 is 56 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com