Hanging heat accumulator for improving radiant tube temperature uniformity

A heat storage body and radiant tube technology, applied in the field of mechanical processing, can solve problems such as uneven temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

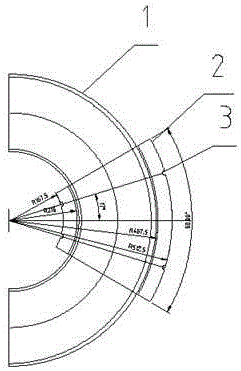

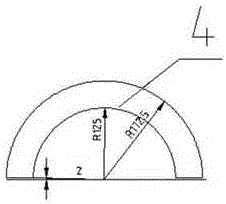

[0039] The present invention takes the regenerator required by the 140 KW external regenerative radiant tube burner as an example. Body groove depth R=125, such as figure 2 shown. The shape of the heat storage body is as figure 1 As shown, the thickness of the heat storage body is 45mm.

[0040] When installing, first connect the flange end of the radiant tube to the burner through the flange, and clamp the upper and lower regenerators in the middle of the radiant tube bend. figure 1 shown. Then lock the heat storage body along the reserved notch of the heat storage body through the hanger snap ring, and fix the radiant tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com