Five-dimensional force sensor structure based on double-layer planar spring

A plane spring and sensor technology, applied in the direction of springs/shock absorbers, spring assemblies composed of several springs, springs, etc., can solve the problem that fiber optic force sensors cannot detect forces in any direction, and achieve easy establishment, compact structure, The effect of easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

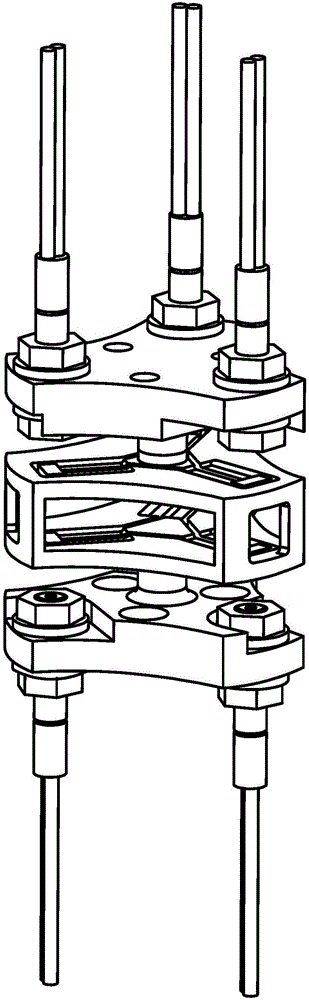

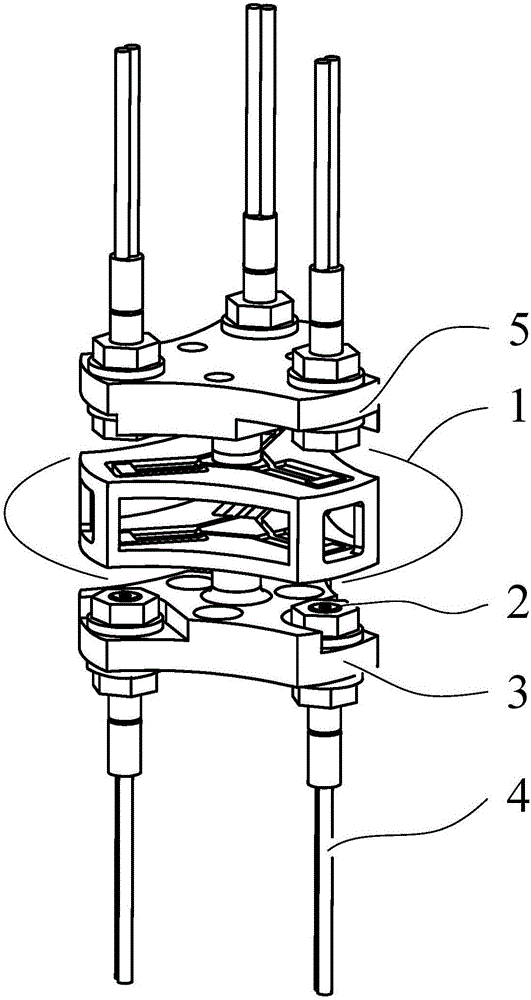

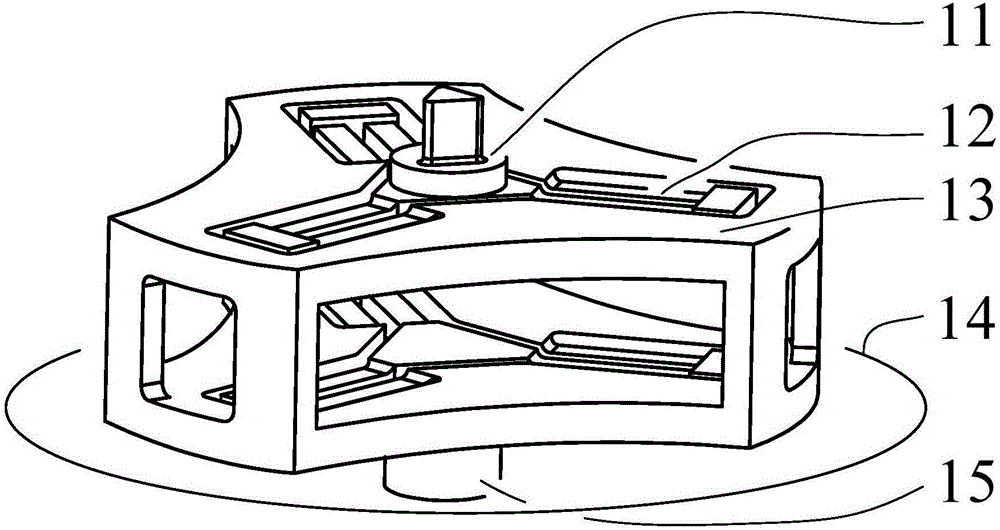

[0017] As shown in the accompanying drawings, the present invention is a double-layer planar spring five-dimensional force sensor structure, which includes a double-layer planar spring structure 1, five optical fiber distance sensors 2, a sensor base 3, five sets of optical fibers 4 for emitting and receiving laser light, and force Input 5. The double-layer planar spring structure is composed of central ends 11 and 15, six groups of elastic beam structures 12, and peripheral ends 13. The two-layer planar springs 14 are connected through the peripheral ends 13, distributed in parallel and separated by a certain distance, and each elastic beam unit One end connects the central ends 11 and 15, and the other end connects the peripheral end 13. The six groups of elastic beam structures are respectively evenly distributed in two planes to form two single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com