Method for determining the content of normax catalyst and its ligand

A catalyst and ligand technology, applied in the field of 2-propyl heptanol production, can solve problems such as inaccurate results, and achieve the effects of accurate results and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

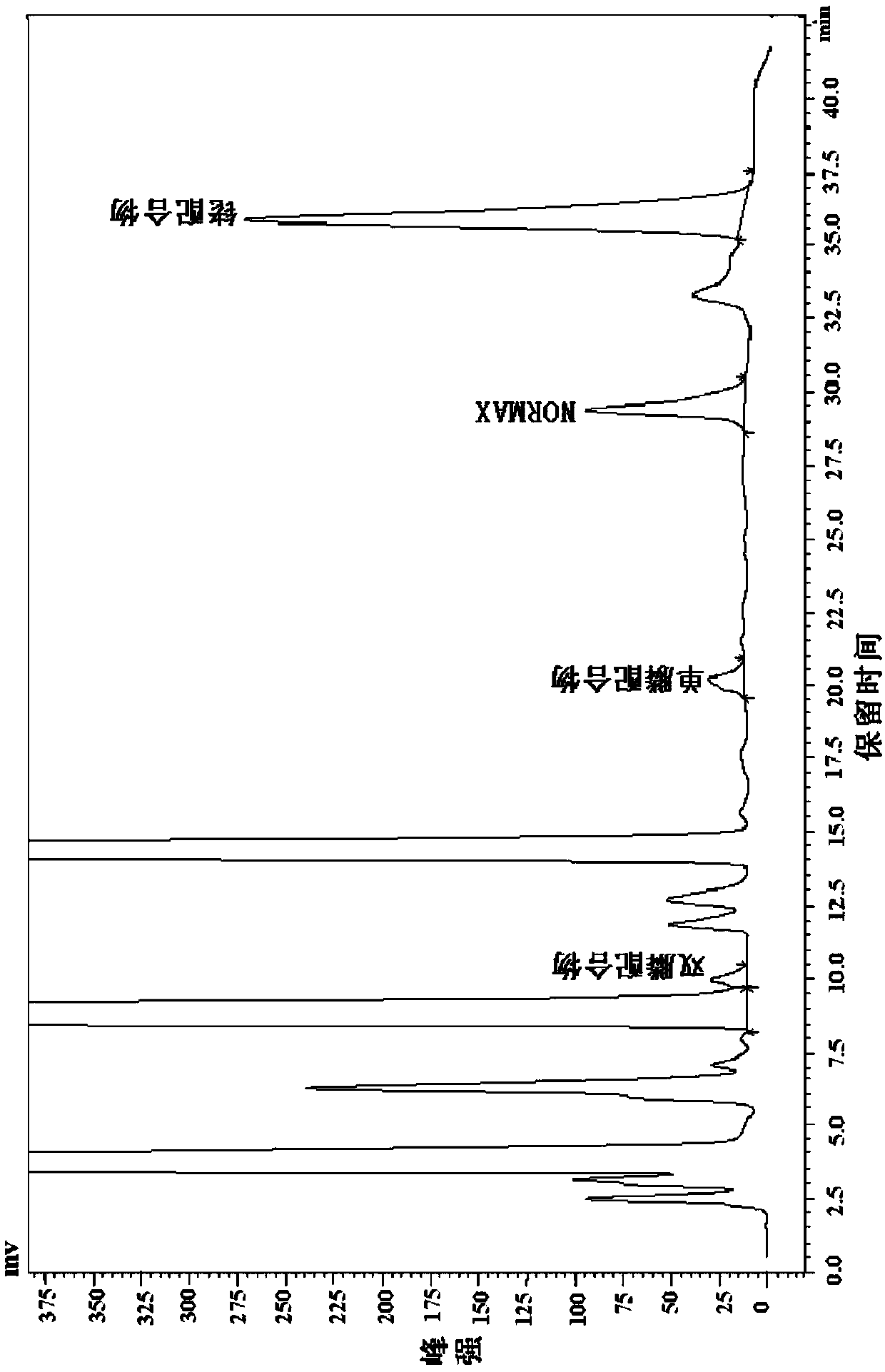

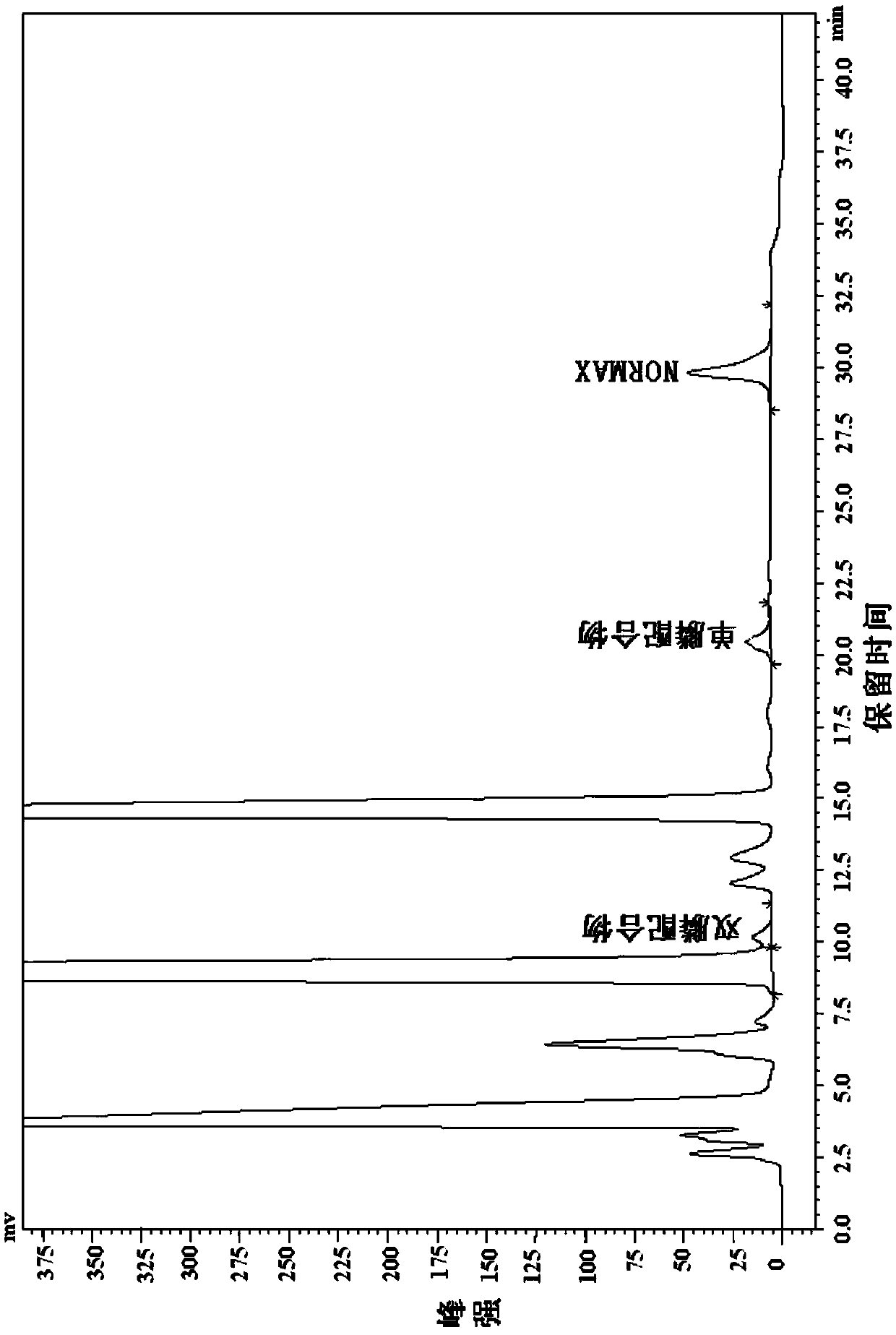

Examples

Embodiment 1

[0026] 1) Preparation of diluent

[0027] Nitrogen is passed into tetraethylene glycol dimethyl ether for degassing to obtain degassed tetraethylene glycol dimethyl ether;

[0028] In a nitrogen glove box, 1.00 g of diphenylcyclohexylphosphine was weighed and placed in a 100 mL glass bottle replaced with nitrogen, and degassed tetraethylene glycol dimethyl ether was added to the above glass bottle to make the diphenyl cyclohexyl phosphine Hexylphosphine was diluted to 100.00g, sealed, and shaken well to dissolve it to obtain the required dilution.

[0029] 2) Preparation of standard solution

[0030] In a nitrogen glove box, weigh 0.1197g of 3,3',5,5'-tetra-tert-butyl-2,2'-diphenol into a nitrogen-substituted 100mL glass bottle, and add to the glass bottle Add dilute solution to 3,3',5,5'-tetra-tert-butyl-2,2'-diphenol to be diluted to 100.0000g, seal and shake well to obtain standard solution, concentration C STD = 0.1197%.

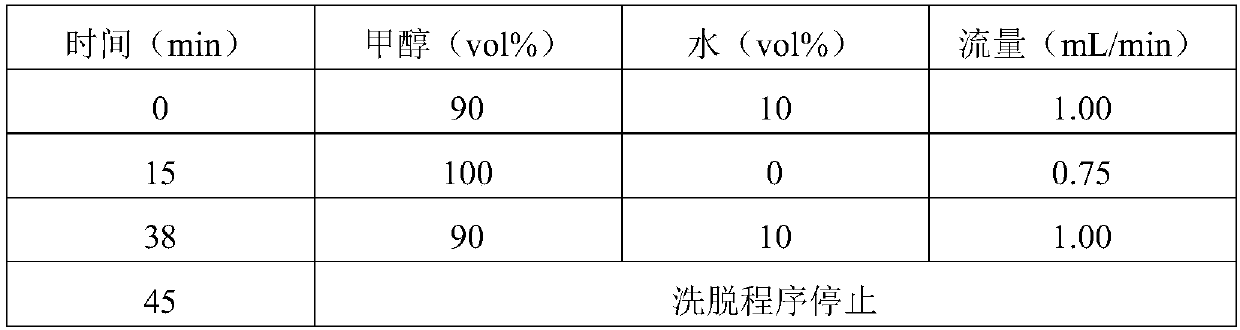

[0031] 3) Calibration process

[0032] Accord...

Embodiment 2

[0039] 1) Preparation of diluent

[0040] Nitrogen is passed into tetraethylene glycol dimethyl ether for degassing to obtain degassed tetraethylene glycol dimethyl ether;

[0041] In a nitrogen glove box, 1.00 g of diphenylcyclohexylphosphine was weighed and placed in a 100 mL glass bottle replaced with nitrogen, and degassed tetraethylene glycol dimethyl ether was added to the above glass bottle to make the diphenyl cyclohexyl phosphine Hexylphosphine was diluted to 100.00g, sealed, and shaken well to dissolve it to obtain the required dilution.

[0042] 2) Preparation of standard solution

[0043] In a nitrogen glove box, weigh 0.1197g of 3,3',5,5'-tetra-tert-butyl-2,2'-diphenol (CAS: 6390-69-8) into a nitrogen-purged glass In the bottle, add diluent solution to dilute to 100.00g, seal and shake well to obtain standard solution, concentration C STD = 0.1197%.

[0044] 3) Calibration process

[0045] According to the chromatographic condition in claim 1, standard sample...

Embodiment 3

[0051] 1) Preparation of diluent

[0052] Nitrogen is passed into tetraethylene glycol dimethyl ether for degassing to obtain degassed tetraethylene glycol dimethyl ether;

[0053] In a nitrogen glove box, 1.00 g of diphenylcyclohexylphosphine was weighed and placed in a 100 mL glass bottle replaced with nitrogen, and degassed tetraethylene glycol dimethyl ether was added to the above glass bottle to make the diphenyl cyclohexyl phosphine Hexylphosphine was diluted to 100.00g, sealed, and shaken well to dissolve it to obtain the required dilution.

[0054] 2) Preparation of standard solution

[0055] In a nitrogen glove box, weigh 0.1065g of 3,3',5,5'-tetra-tert-butyl-2,2'-diphenol into a nitrogen-substituted 100mL glass bottle, and add to the glass bottle Add dilute solution to 3,3',5,5'-tetra-tert-butyl-2,2'-diphenol to be diluted to 100.00g, seal and shake well to obtain standard solution, concentration C STD = 0.1065 wt%.

[0056] 3) Calibration process

[0057] Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com