Intelligent control system and method for semiconductor manufacturing device and technology

A technology for intelligent control systems and manufacturing equipment, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of continuous learning, human factors, and reduced production capacity, and achieve abnormal event handling The loss of experience, the effect of solving the difference of process results and ensuring the quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

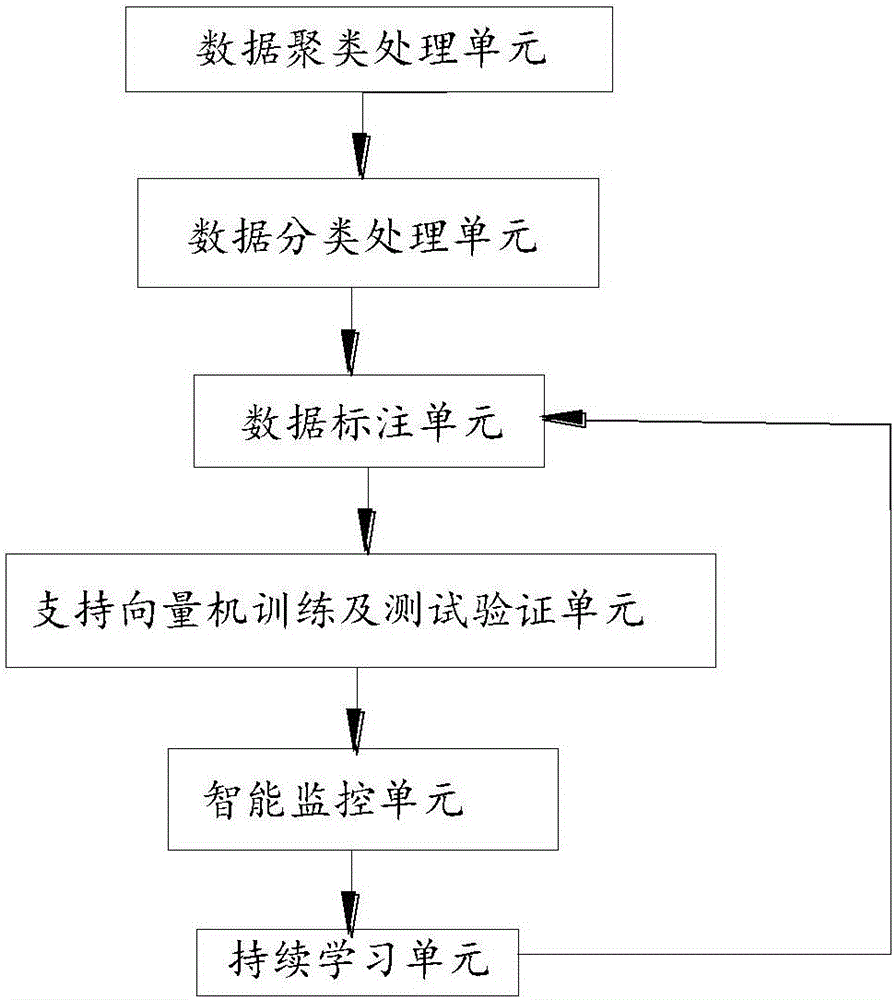

[0037] Such as figure 1As shown, an intelligent control system for semiconductor manufacturing equipment and processes is provided on the one hand according to an embodiment of the present invention, including a data clustering processing unit, a data classification processing unit, a data labeling unit, a support vector machine training and testing verification unit, and an intelligent Monitoring unit, continuous learning unit;

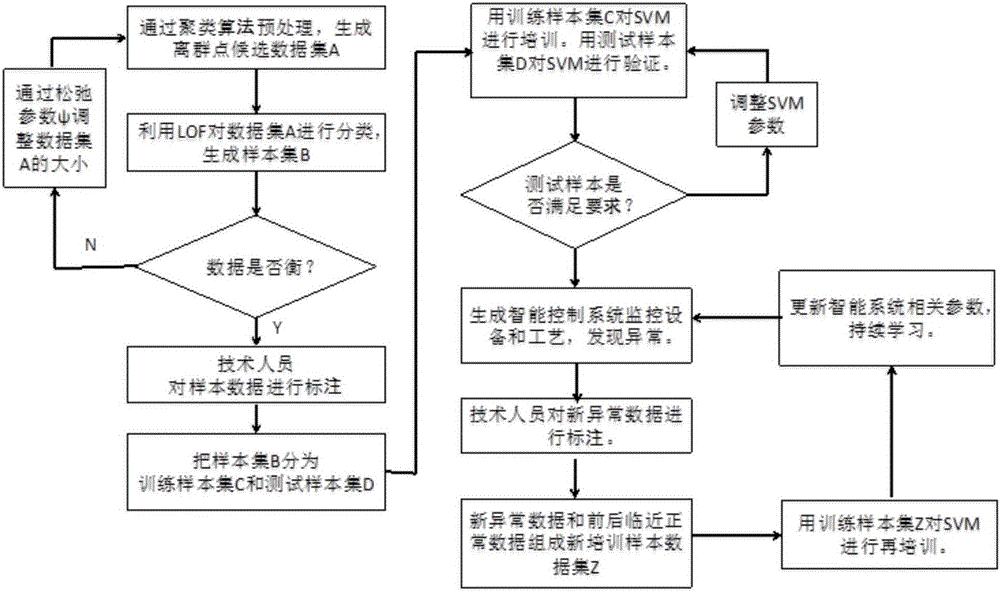

[0038] The data clustering processing unit preprocesses the data collected by the semiconductor manufacturing equipment and process through the K-means clustering algorithm and executes the outlier judgment algorithm to obtain the outlier point candidate set A;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com