Preparation method of anisotropic nanocrystalline ndfeb dense permanent magnet

An anisotropic and nanocrystalline technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of high rare earth content, low rare earth content, low production cost, etc., and achieve simple preparation process, rare earth Less, less costly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

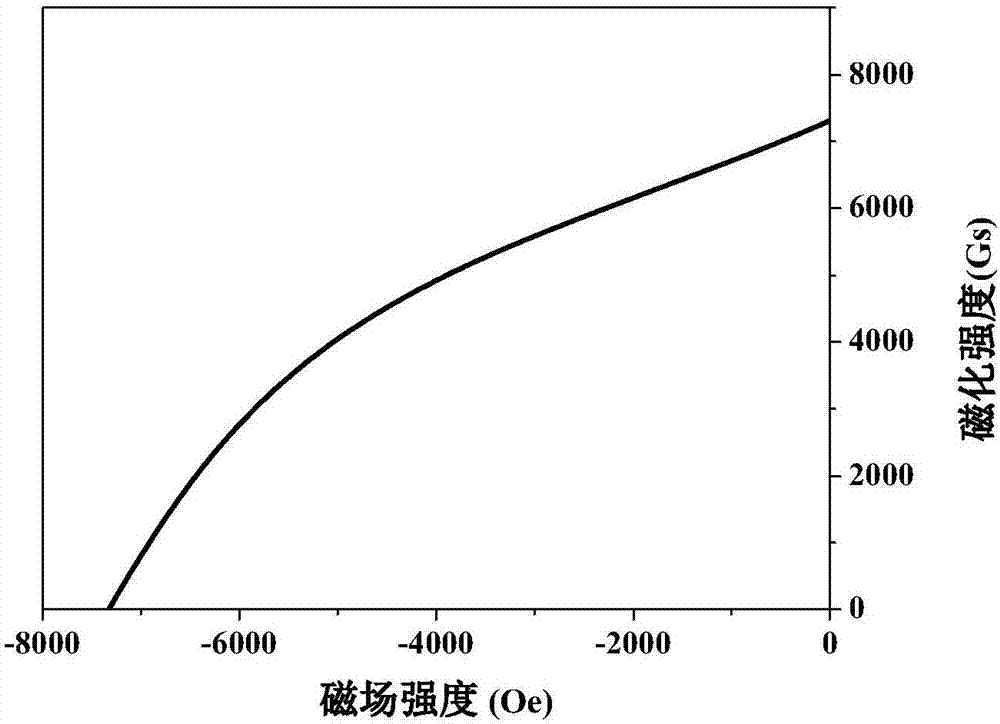

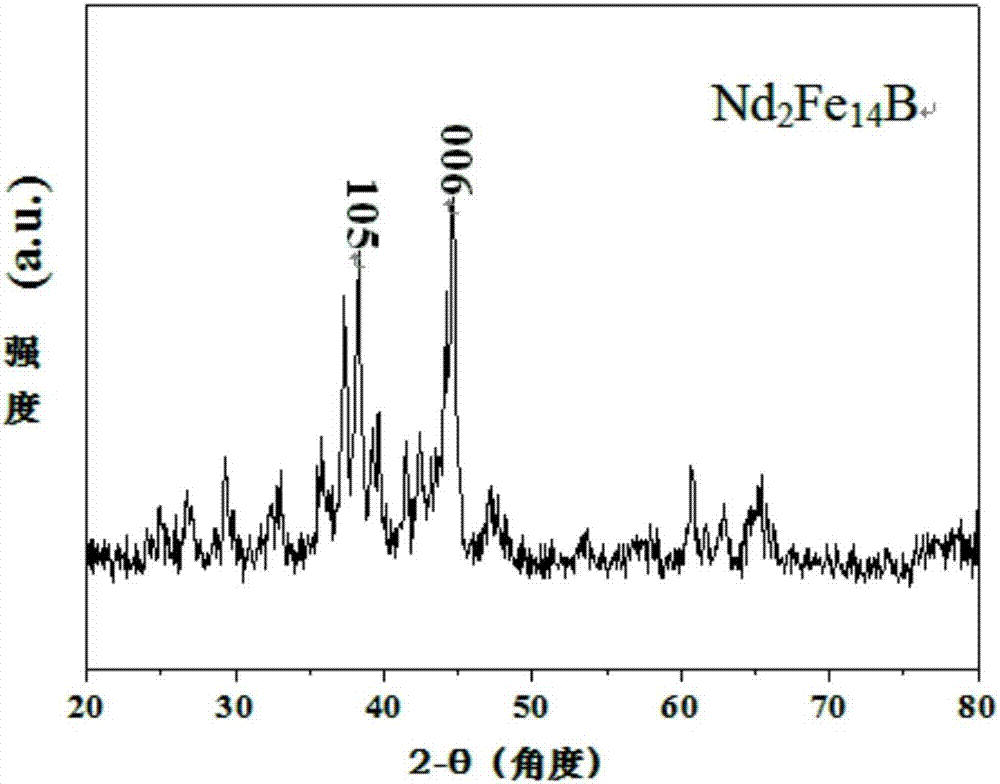

[0024] Embodiment 1, test sample I, a kind of preparation method of anisotropic nanocrystalline NdFeB dense permanent magnet, is prepared according to the following steps:

[0025] Step 1. According to Nd 11.5 Fe 81.5 Zr 1 B 6 The molar ratio of the alloy raw materials is configured, and the alloy ingot is made by using the magnetic levitation melting method, and the alloy ingot is repeatedly smelted three times to make the composition of the alloy ingot uniform, and then the alloy ingot is broken into small pieces and then melted quickly The alloy thin strip is made by quenching method, filled with argon gas during the rapid quenching process, the strip is vacuum-spun, and the roller speed is 30m / s, and the alloy thin strip is ground into 150μm Nd in a glove box. 11.5 Fe 81.5 Zr 1 B 6 alloy powder,

[0026] Step 2, utilizing the arc evaporation method to prepare nano-zinc powder, then adding the prepared nano-zinc powder to the Nd 11.5 Fe 81.5 Zr 1 B 6 In the alloy...

Embodiment 2

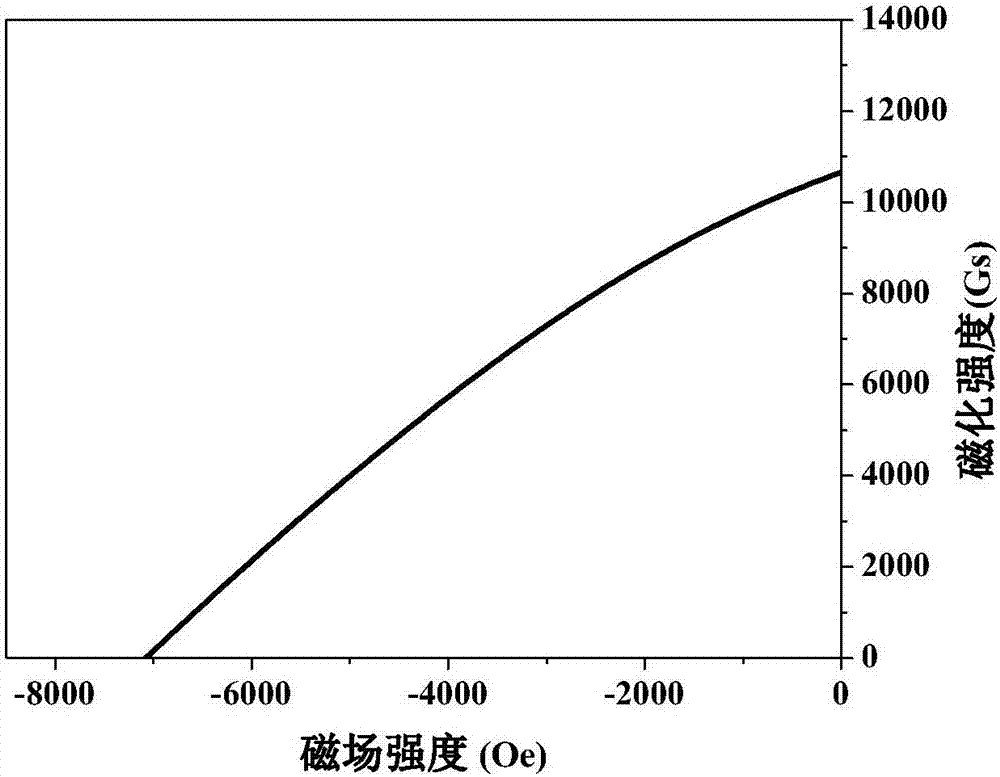

[0028] Embodiment 2, test sample II, a method for preparing an anisotropic nanocrystalline NdFeB dense permanent magnet, is prepared according to the following steps:

[0029] Step 1. According to Nd 11.5 Fe 81.5 Zr 1 B 6 The molar ratio of the alloy metal raw materials is configured, and the alloy ingot is made by magnetic levitation melting, and the alloy ingot is repeatedly smelted three times to make the composition of the alloy ingot uniform, and then the alloy ingot is broken and made by the melt rapid quenching method The alloy thin strip is filled with argon gas during the rapid quenching process, the strip is vacuum-spun, and the roller speed is 30m / s, and the alloy thin strip is ground into Nd with a particle size of 200 μm in a glove box. 11.5 Fe 81.5 Zr 1 B 6 alloy powder;

[0030] Step 2, utilizing the arc evaporation method to obtain spherical nano-zinc particles, and adding the prepared nano-zinc particles to the Nd 11.5 Fe 81.5 Zr 1 B 6 In the alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com