Full-automatic fresh lotus seed core remover

A fully automatic core-through machine technology, applied in food science, applications, fruit pitting devices, etc., can solve problems such as low work efficiency, high labor intensity, and poor processing quality, so as to save heavy work and reduce land occupation Area, the effect of ensuring the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

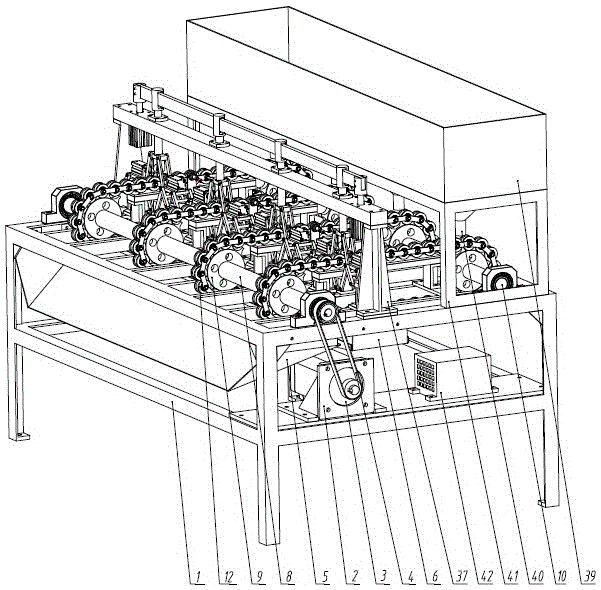

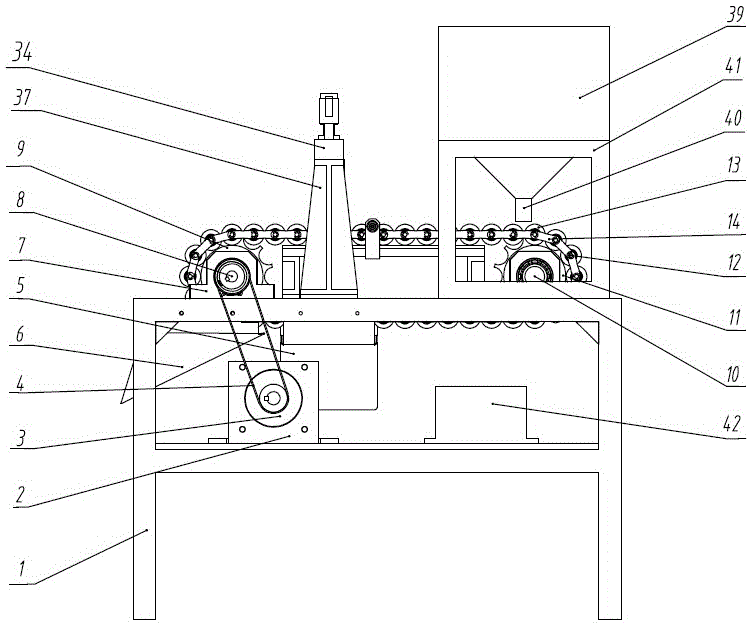

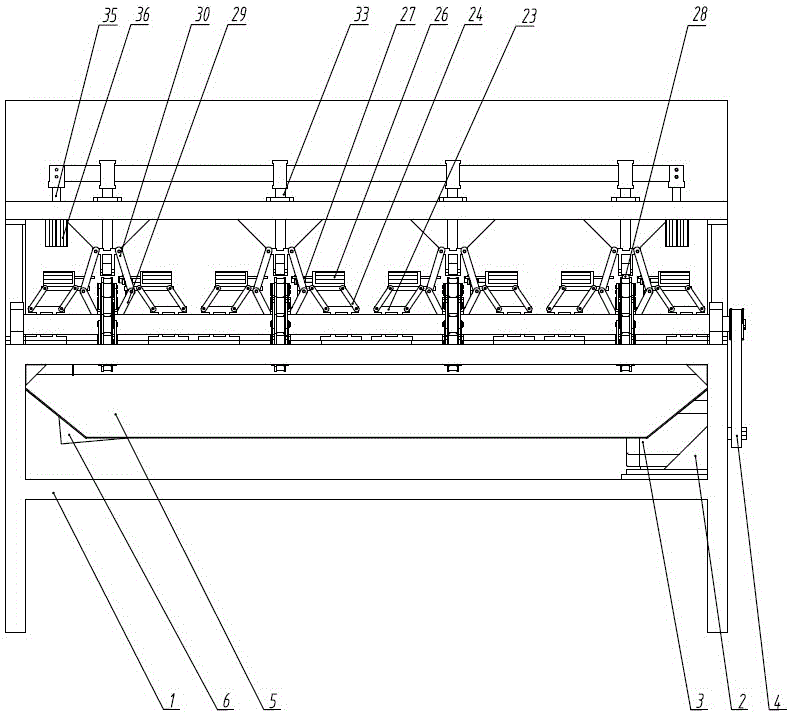

[0023] Such as Figure 1 to Figure 7 As shown, a kind of full-automatic fresh lotus seed core machine of the present invention, it is that at least one group of core mechanism is installed side by side on frame 1, and the bottom of core mechanism is installed with core lotus discharge hopper 5, and lotus core discharge hopper 6. A feed hopper 39 is installed above the core mechanism; the feed hopper 39 is installed above the roller chain 12 in the core mechanism through a feed bracket 41, and the feed trough 40 below the feed hopper 39 is For roller chain 12.

[0024] The core-through mechanism is that a driving sprocket 9 and a driven sprocket 11 are installed above the frame 1, and the stepper motor 3 drives the sprocket driving shaft 8 on the driving sprocket 9 through a synchronous belt 4 to rotate. The roller chain 12 that conveys the lotus seeds 28 and realizes the axis of the lotus seeds 28 to be parallel to the core-through punch 27 is installed on the sprocket. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com