Composite atomizing plate and manufacturing method thereof

A production method and technology of atomized tablets, which are applied in the field of atomized tablets, can solve the problems of fragments being inhaled into the lungs by patients, uneven pore size distribution, shortened service life, etc., achieve excellent chemical stability, simple and reliable installation, and improve The effect of atomization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

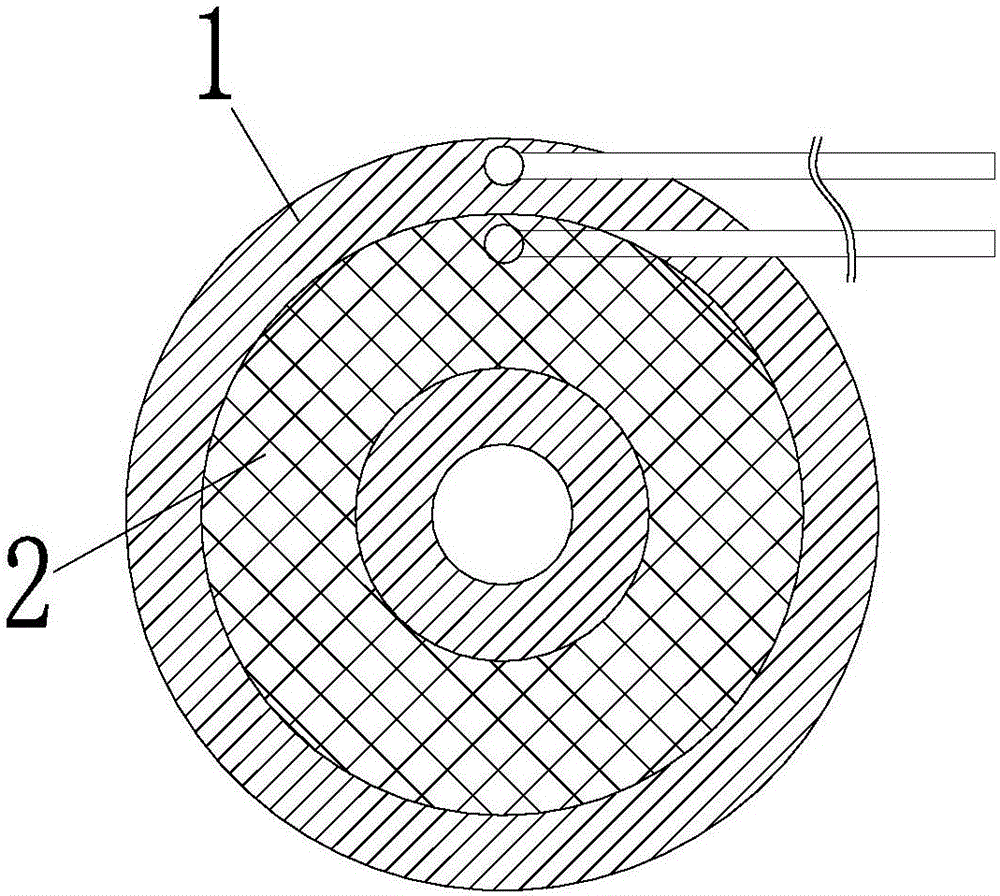

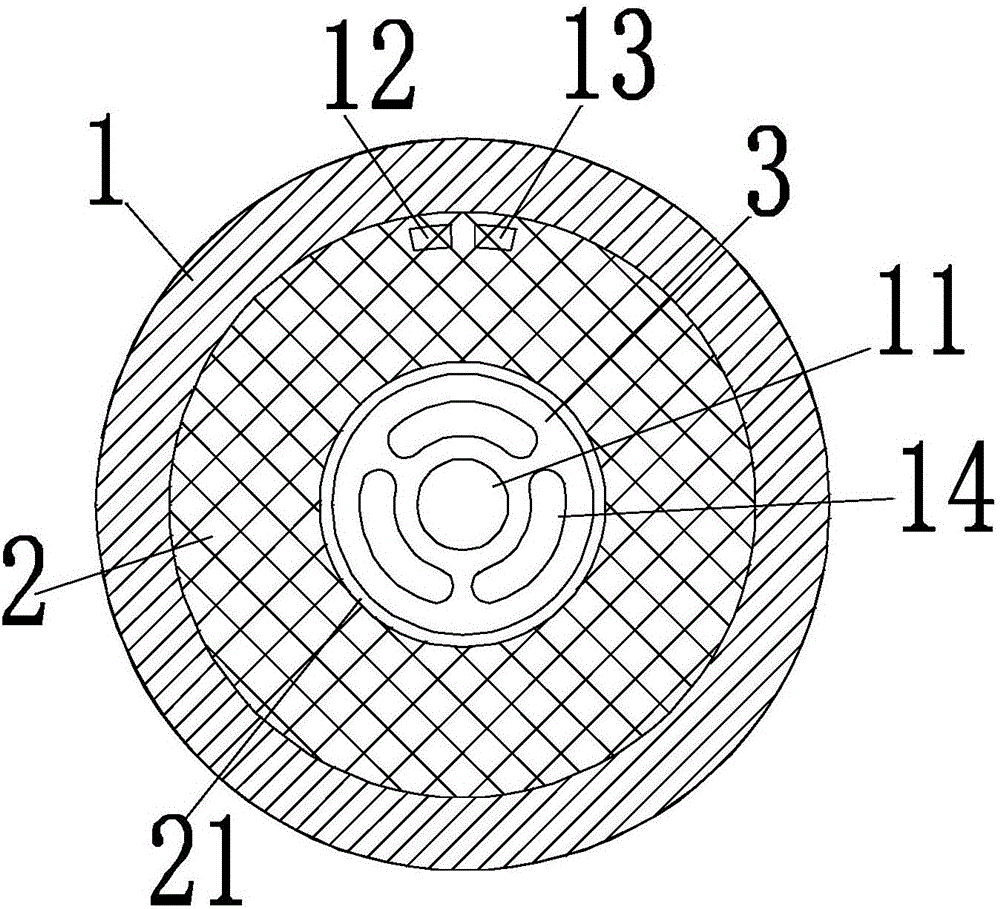

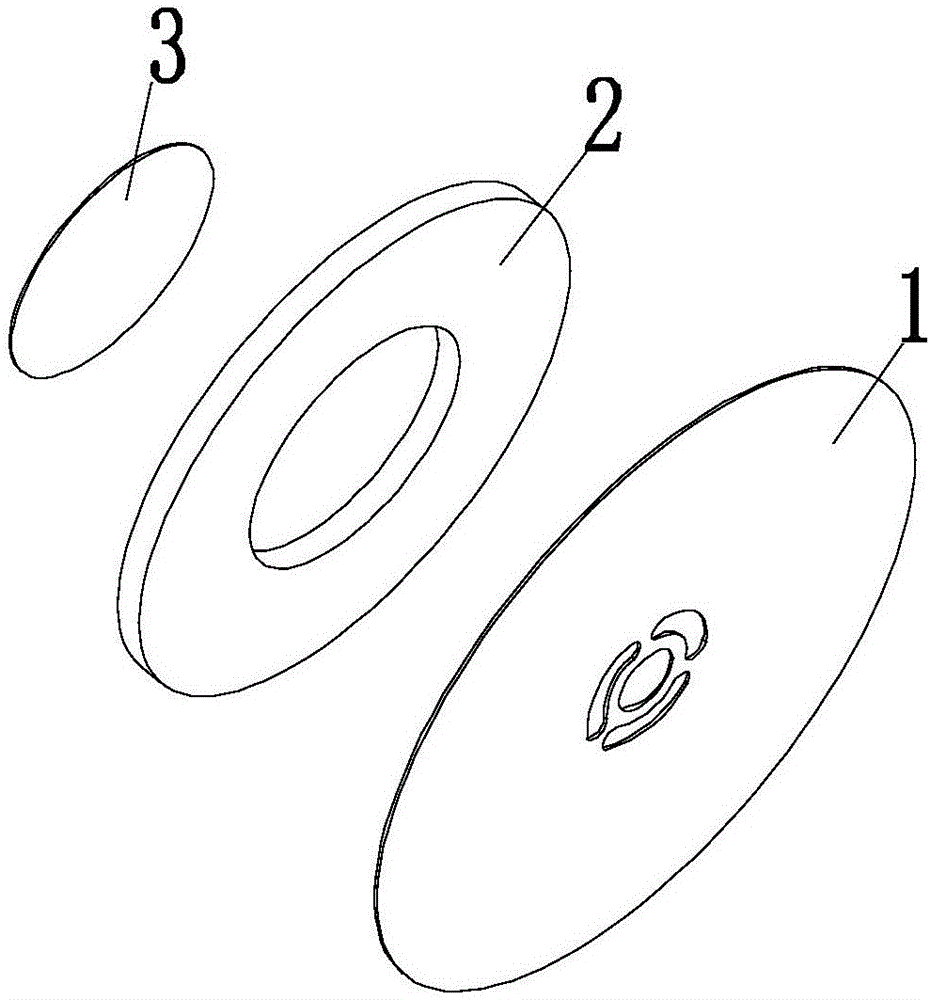

[0035] refer to Figure 2-4 , a composite atomizing sheet in this embodiment, including a metal substrate 1 and a piezoelectric ceramic ring 2 fixed on the upper surface of the metal substrate 1;

[0036] The central area of the metal substrate 1 is provided with a first through hole 11, and the upper surface of the metal substrate 1 is also respectively provided with a positive electrode pad 12 and a negative electrode pad 13; There are three waist holes 14 , and the three waist holes 14 are evenly distributed along the circumference of the first through hole 11 . The central area corresponding to the first through hole 11 on the piezoelectric ceramic ring piece 2 is provided with a second through hole 21; the positive pad 12 and the negative pad 13 are distributed on the piezoelectric ceramic along the same circumference. On the upper surface of ring piece 2. The metal substrate 1 is a stainless steel substrate; the outer diameter of the piezoelectric ceramic ring 2 is s...

Embodiment 2

[0052] The characteristic of this embodiment is: the diameter of the small-radius opening of the atomization hole is 3 microns, and the diameter of the large-radius opening is 10 microns. Others are the same as in Example 1.

Embodiment 3

[0054] The characteristic of this embodiment is: the diameter of the small-radius opening of the atomization hole is 2 microns, and the diameter of the large-radius opening is 8 microns. Others are the same as in Example 1.

[0055] Other embodiments:

[0056] Two, four, five, six or more round holes are also arranged on the metal substrate. The outer diameter of the piezoelectric ceramic ring is equal to the diameter of the metal substrate. Unless otherwise specified, each part involved in the present invention can also be purchased directly from the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com