Low-sulfur curing agent for casting furan resin

A technology of furan resin and curing agent, which is applied in the direction of casting molding equipment, casting molds, manufacturing tools, etc., can solve the problems of accelerated hardening speed and low mold strength, and achieve the goals of faster hardening speed, high casting strength and improved pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Put 35 parts by weight of toluene into a four-neck glass reactor with stirring. The temperature is raised to 40°C, and 20 parts by weight of sulfuric acid are added dropwise. After the addition is completed, the temperature is raised to 105°C and reacted at 105-115°C for 8-10 hours. After the reaction is over, 35 parts by weight of salicylic acid or citric acid or oxalic acid, 25 parts by weight of water, and 2 parts by weight of animal glue are added after cooling down 30°C for 30 minutes, and then discharged.

[0028] Control 1: Existing sulfonic acid curing agent GS04, produced by Suzhou Xingye Material Technology Co., Ltd.

[0029] Comparison 2: The existing low-sulfur curing agent 04 is produced by Suzhou Xingye Material Technology Co., Ltd.

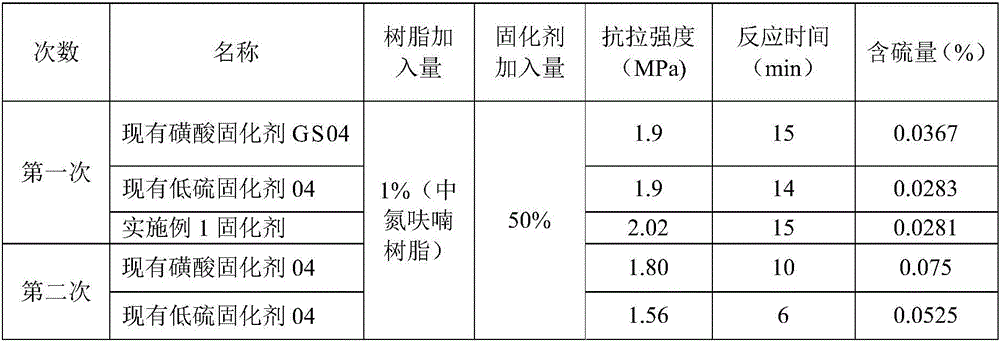

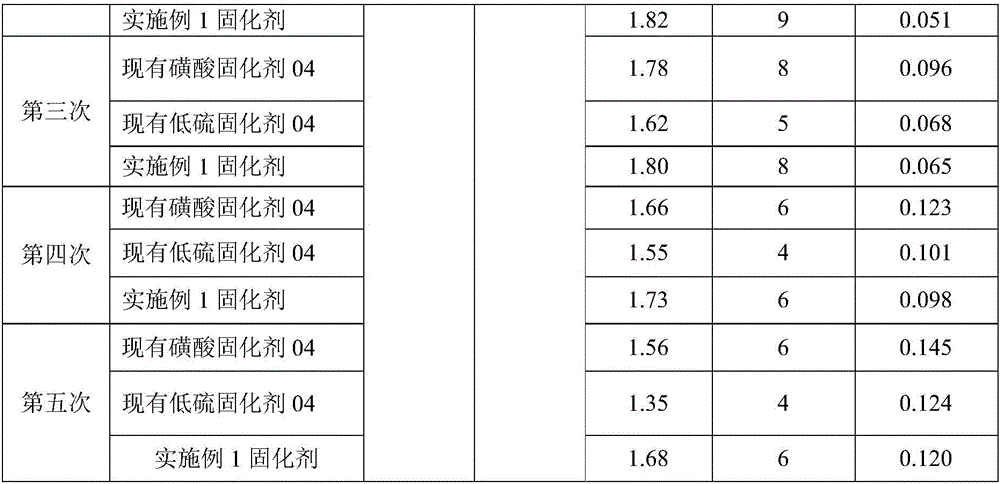

[0030] The above-mentioned Examples and Controls 1 and 2 were prepared according to conventional methods to obtain furan resin curing agents, and then furan resin molding sand samples were prepared by the methods required in JB / T 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com