Braze-welding method for ceramic or ceramic-based composite material and metal through composite interlayer

A technology of composite intermediate layer and composite material, applied in the field of composite intermediate layer brazing ceramics or ceramic matrix composite materials and metals, can solve the problems of high residual stress and low reliability of brazed joints, achieve stable product performance and improve joints. Strength, the effect of improving the distribution state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

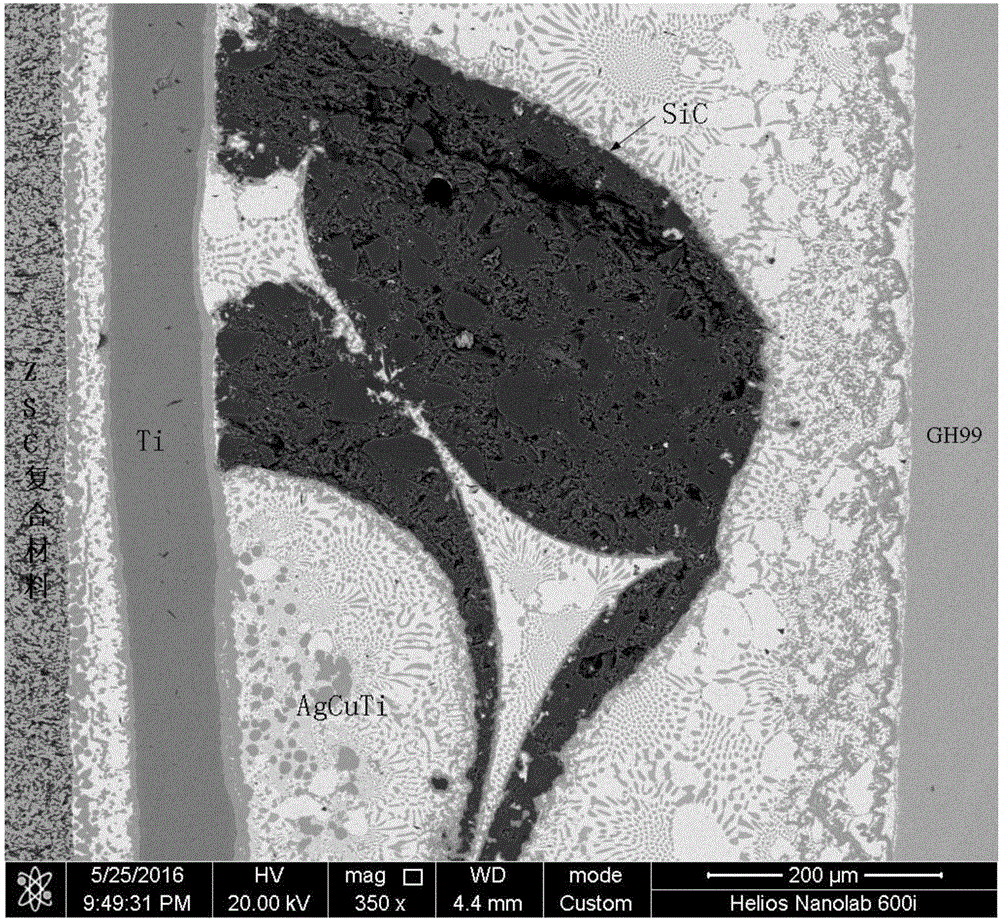

[0016] Specific implementation mode 1: In this implementation mode, the method for brazing ceramics or ceramic-based composite materials and metals with a composite intermediate layer is realized according to the following steps:

[0017] 1. Polish the ceramics or ceramic matrix composite materials to be welded, metal materials to be welded, porous ceramics, Ti foil and AgCuTi foil with sandpaper, and then wash with acetone for 10-20 minutes to obtain a clean ceramic or ceramic matrix composite to be welded. Materials, metal materials to be welded, porous ceramics, Ti foil and AgCuTi foil solder;

[0018] 2. Put the clean porous ceramics into the mold, then coat the porous ceramics with AgCuTi powder solder to form the intermediate layer, and then place the intermediate layer in a vacuum brazing furnace at a heating rate of 2°C / min~50°C / Min heat up to 840°C-920°C, keep warm for 1min-30min, cool to room temperature and cut into foils to obtain ceramic-metal dual-phase continuo...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that step 1 uses 80#~1000# SiC sandpaper to polish the ceramics or ceramic matrix composite materials to be welded, metal materials to be welded, porous ceramics, Ti foil and AgCuTi foil Solder. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the ceramic or ceramic matrix composite material to be welded described in step one is ZrB 2 -SiC-C ceramic matrix composites, ZrB 2 -SiC ceramic matrix composites, C / SiC ceramic matrix composites, C / C composites, SiC ceramics, ZrB 2 Ceramic, ZrO 2 Ceramic, Al 2 o 3 ceramic or graphite. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com