Design and manufacturing method of a porous grid structure material

A grid structure and porous material technology, applied in the direction of additive processing, medical science, tissue regeneration, etc., can solve the problems of uncertainty, blindness of porous material performance, etc., to improve mechanical and physical properties, shorten structural design and Product manufacturing time, the effect of widening the range of material processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

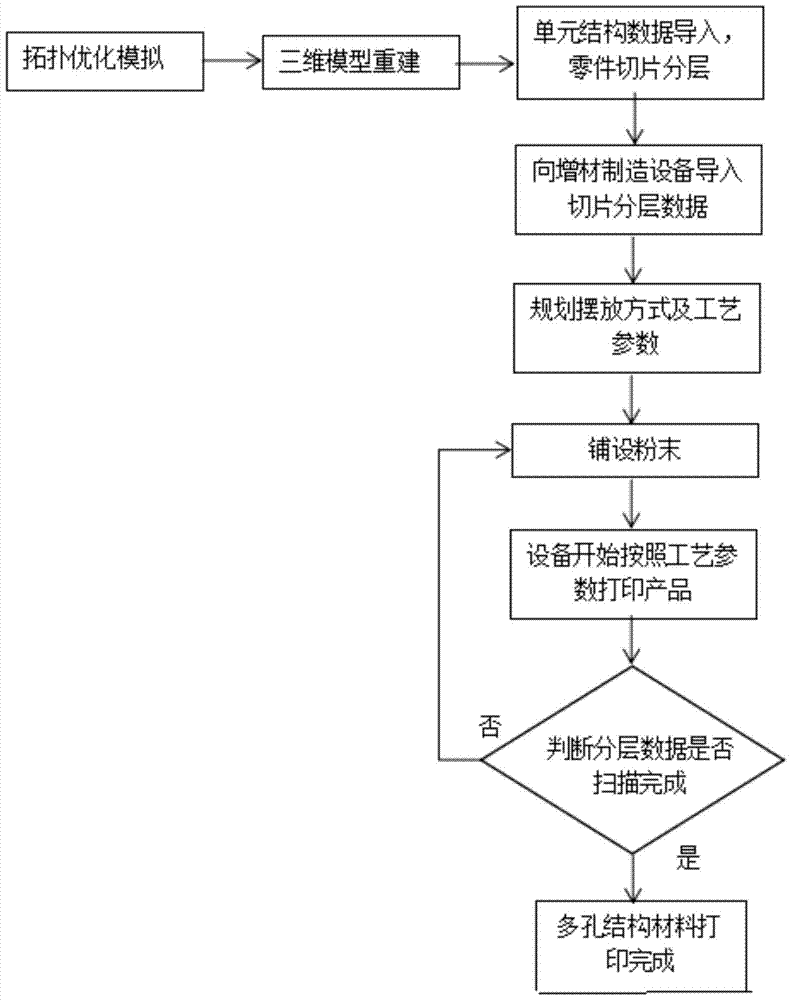

Method used

Image

Examples

Embodiment 1

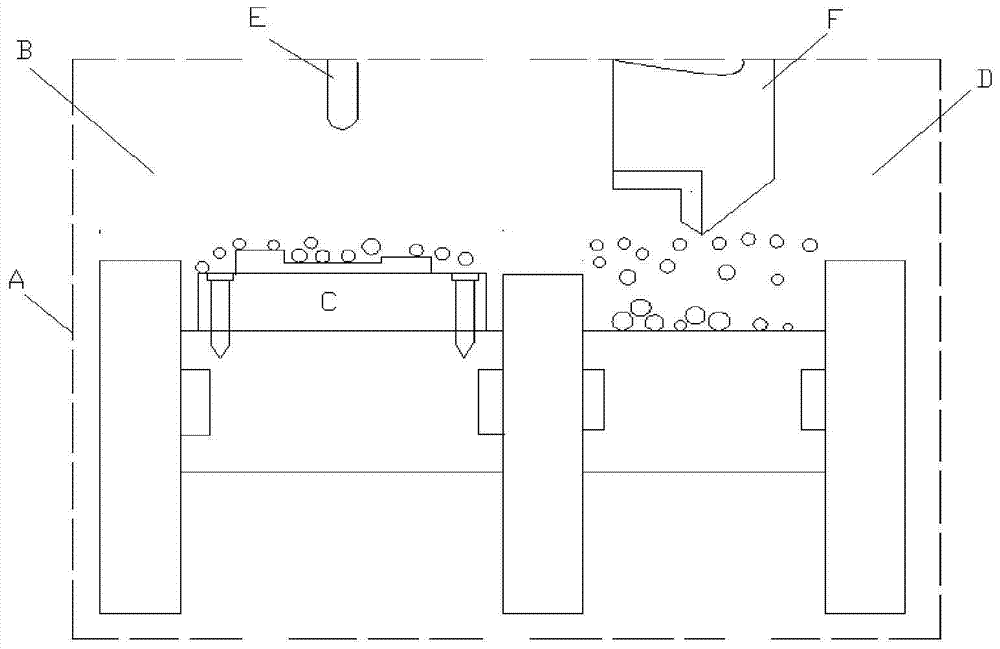

[0033] A 3D printing manufacturing method for a porous implant skeleton. The additive manufacturing equipment adopts EOSM280, the supporting software is PSW3.5, and the material adopts EI Ti6al4v.

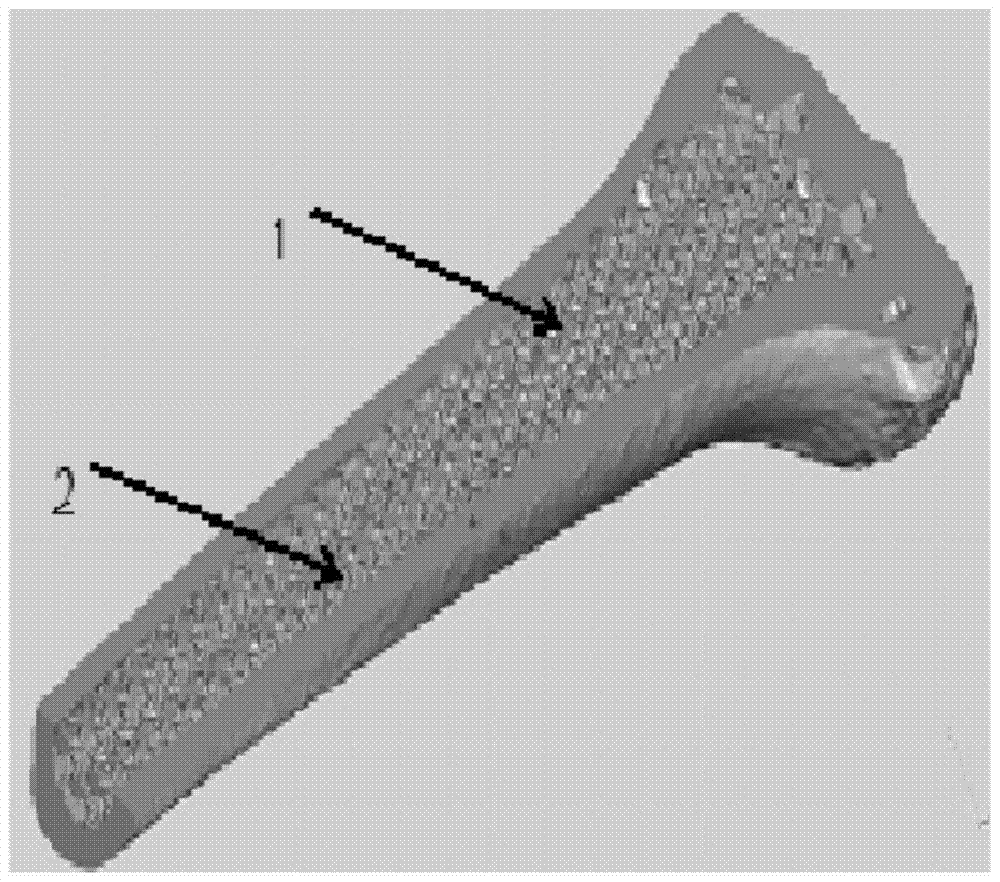

[0034] 1. According to the porous implanted bone model that needs to be manufactured, fill the core that needs to be filled into the topology-optimized porous unit grid structure of appropriate size. The support cannot be removed after the internal pores are formed, so the design should be adjusted reasonably to avoid increasing Internal support that is difficult to remove;

[0035] 2. Fill the ELI Ti6al4v powder into the M280 powder spreading tank;

[0036] 3. Use the software RP-Tools to slice and layer the three-dimensional graphics of the porous implanted bone, with a layer thickness of 10 μm; the obtained series of two-dimensional slice data are imported into the software EOS PSW3.5, which automatically calculates the The laser scanning path of each layer of two-dimensional g...

Embodiment 2

[0044] A porous unit grid structure, first by establishing a 20×20×20 cube model in the simulation software ANSYS, the upper right corner (20,20,20) is subjected to a concentrated load force, and the lower left corner (0,0,0) and its surroundings are fixed ends, input the elastic modulus and Poisson's ratio of the solid material itself without pores and the desired volume fraction. Divide the grid into 20 layers, set the topology optimization control process (ACCUR (accuracy) = 0.001, ITER (iterations) = 20) and solve to obtain the final density cloud map, and finally control the output density in the density cloud map to the red part above 0.8 . During the modeling process, the density cloud image is divided into 20-30 sections along the X-axis direction through the application software SolidWorks, and the images with a density exceeding 0.8 in the section density information are positioned and recorded by the drawing software, and finally staked out and connected until the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com