A torsion beam hub bracket assembly

A technology of bracket assembly and torsion beam, which is applied in the direction of suspension, wheel, wheel assembly and disassembly equipment, etc., can solve the problem that the mounting surface of the wheel hub assembly is not perpendicular to the axis of the bolt hole, and the bolt is loose, so as to reduce the section milling process , production cost reduction, and the effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

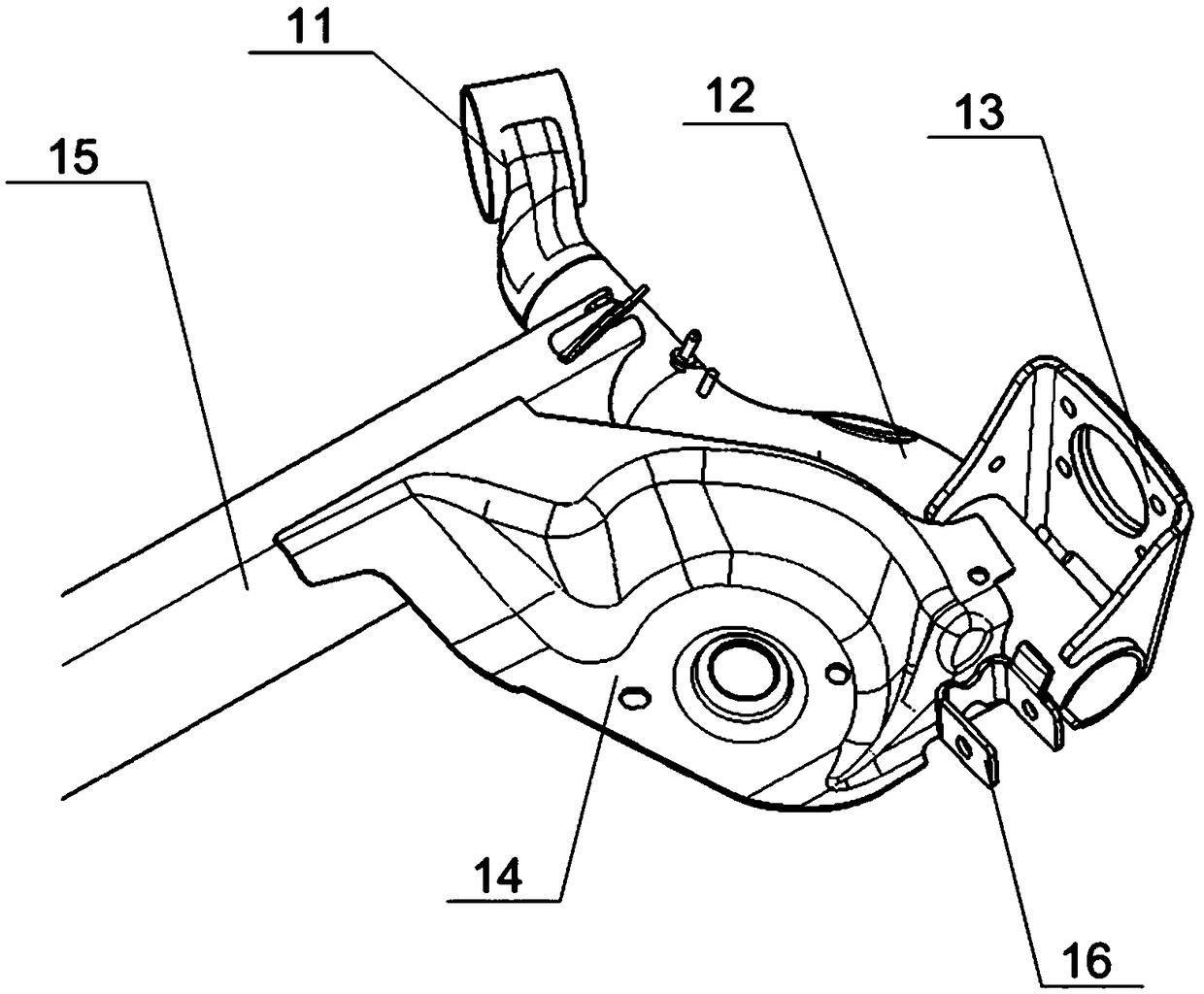

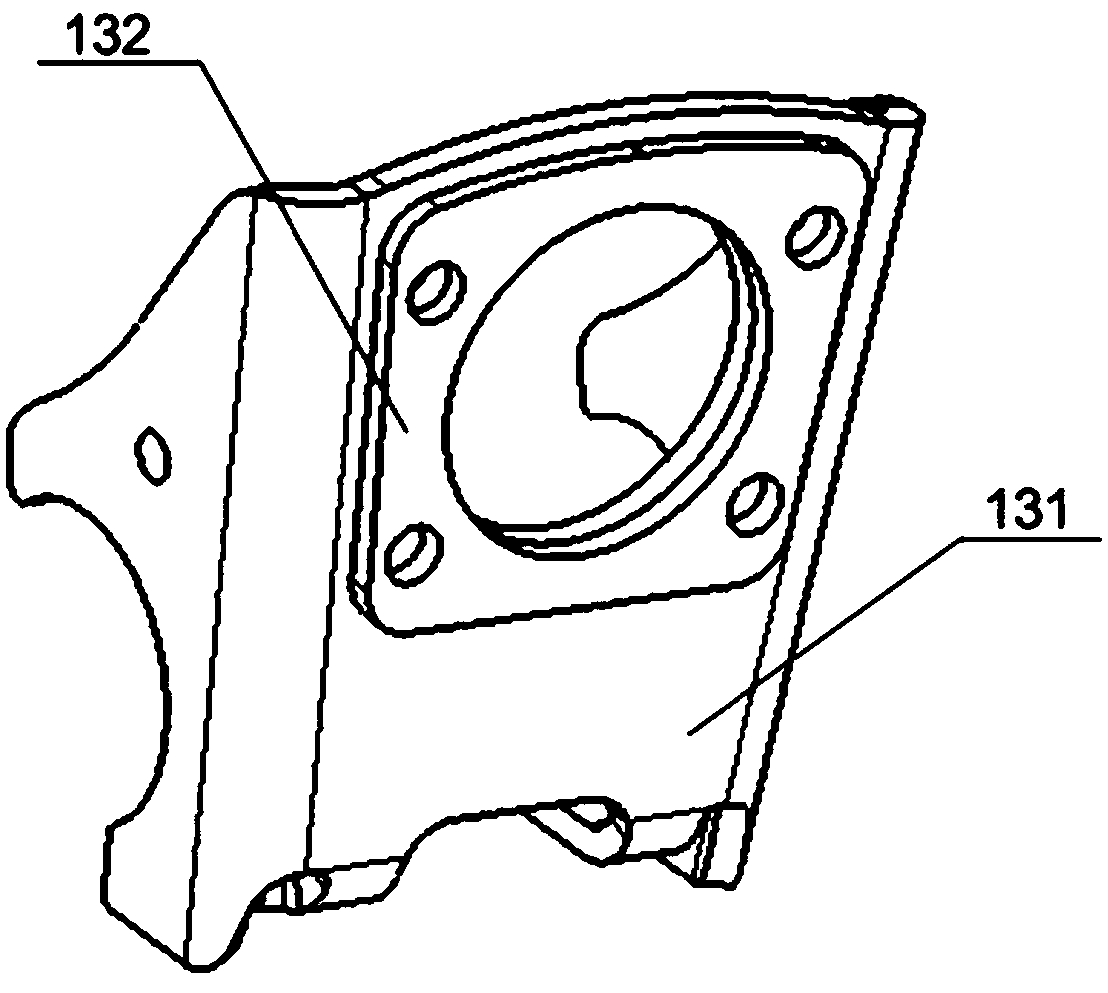

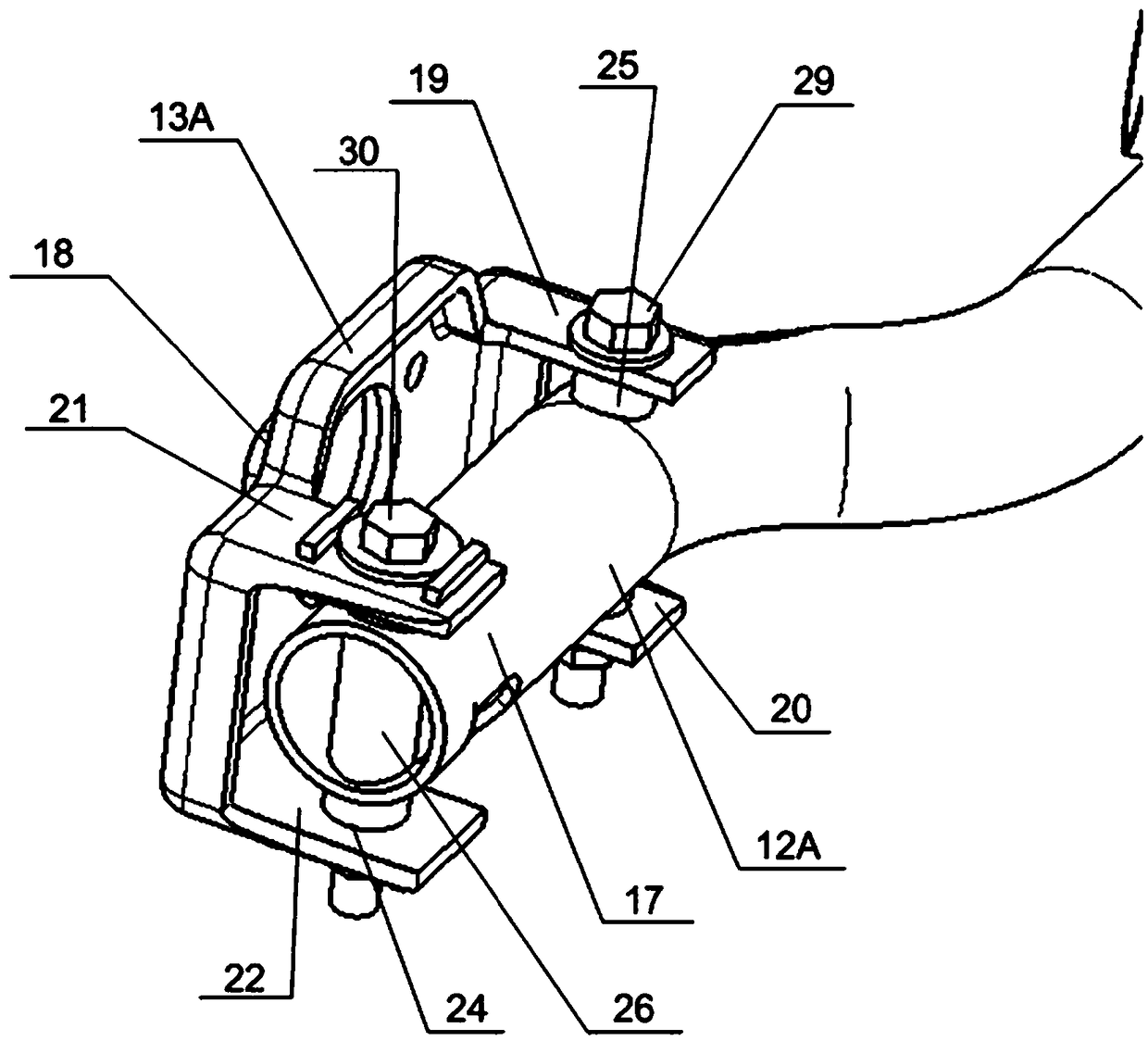

[0028] Such as Figure 3-Figure 5 As shown, the torsion beam hub bracket assembly provided by the embodiment of the present invention includes a hub bracket 13A and a longitudinal arm assembly 17, and the hub bracket 13A includes a mounting plate 18 for fixing the hub assembly, a front mounting foot 19, a front mounting Foot 20, rear mounting foot 21 and rear mounting foot 22, each described front mounting foot 19,20 is all provided with first mounting hole 23, each described rear mounting foot 21,22 is provided with second mounting hole 24. The trailing arm assembly 17 includes a trailing arm 12A, a front bushing 25 and a rear bushing 26. The trailing arm 12A is provided with a first through hole group 27 and a second through hole group 28. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com