Reverse osmosis concentrated water recycling method and system

A technology of reverse osmosis concentrated water and permeate water, applied in the direction of permeation/dialysis water/sewage treatment, etc., can solve the problems of direct discharge of reverse osmosis concentrated water, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

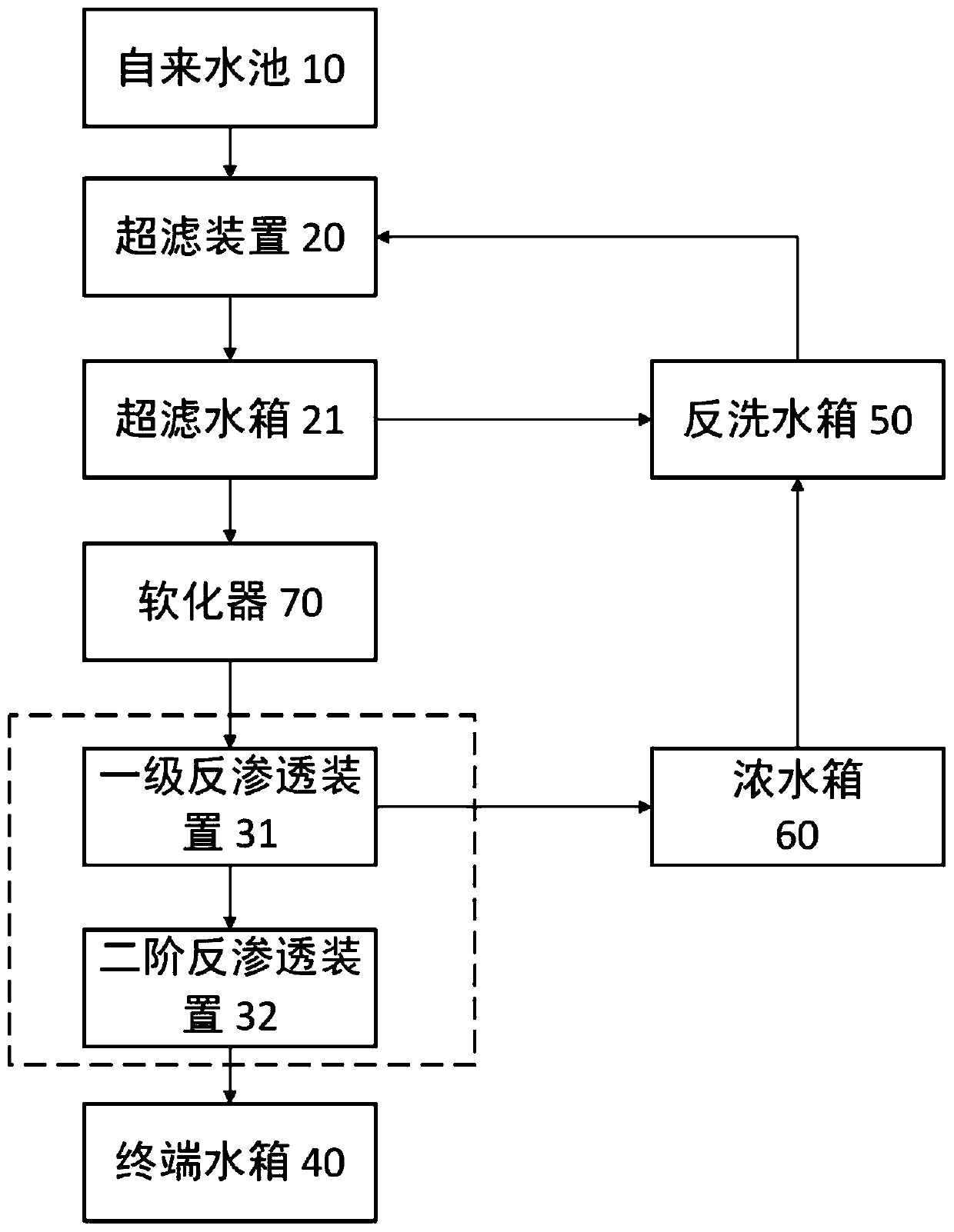

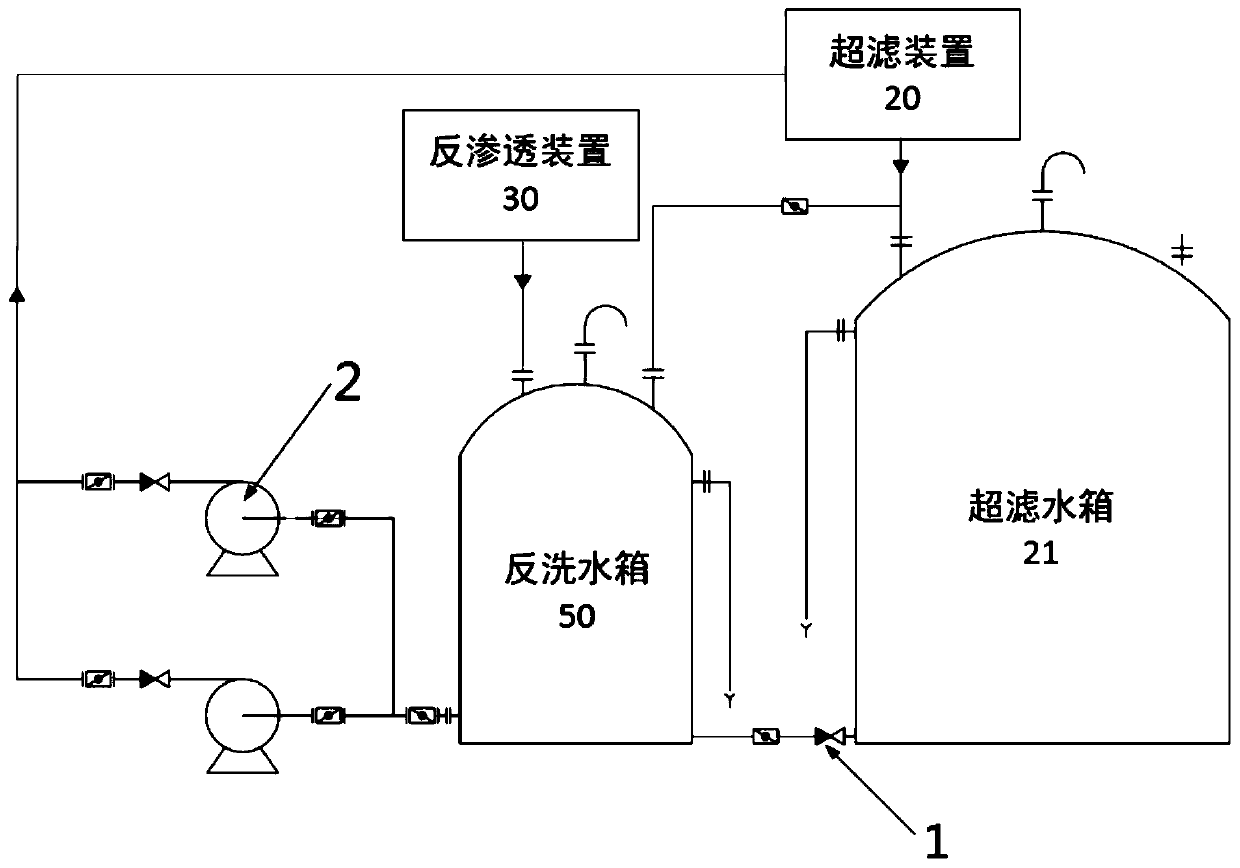

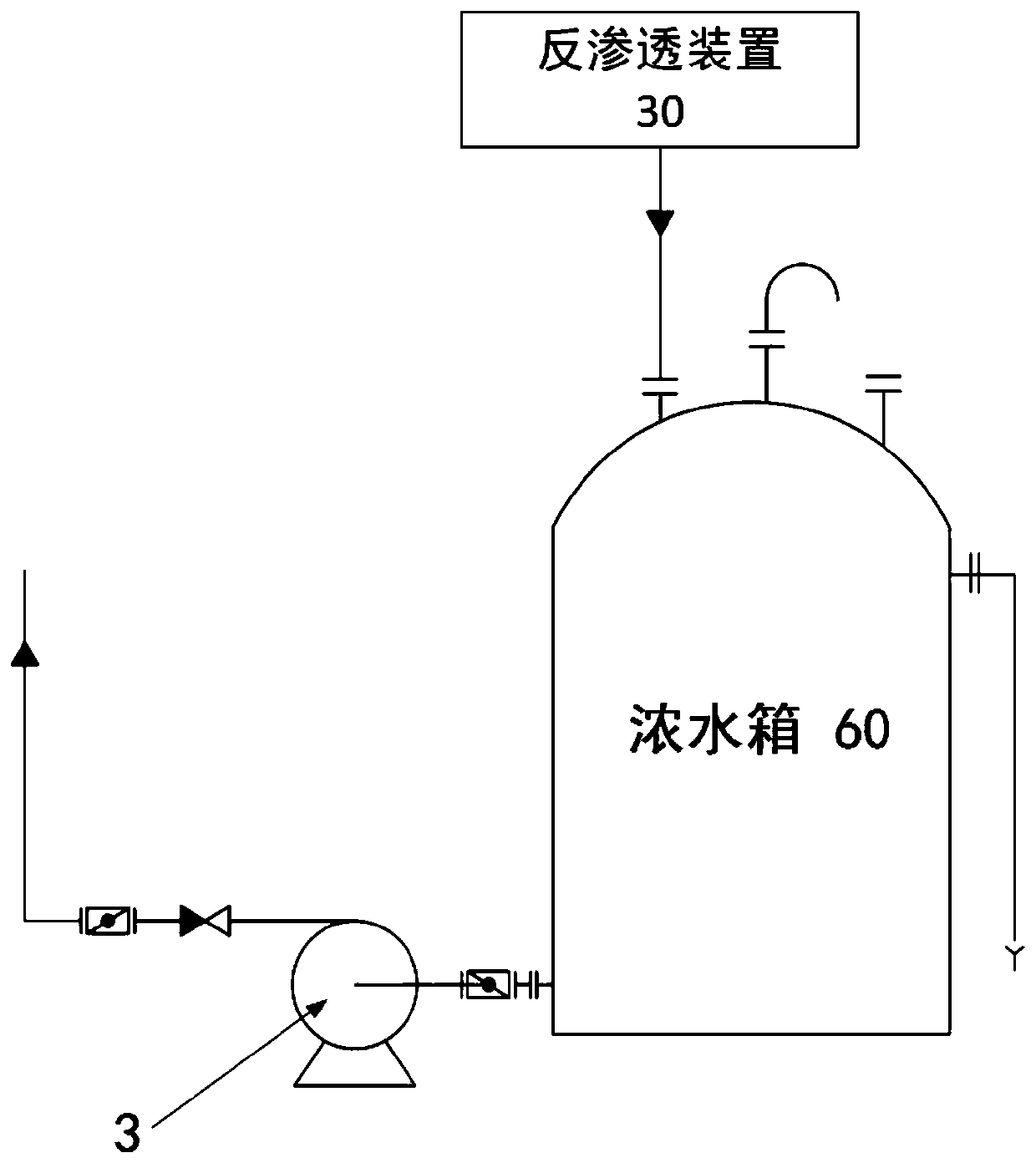

[0031] In the water treatment process flow, the water in the tap water pool 10 is filtered by the ultrafiltration device 20 to obtain ultrafiltered water, the ultrafiltered water is softened to obtain softened water, and the softened water is treated by the reverse osmosis device 30 to obtain permeated water and reverse Infiltrate the concentrated water, the permeated water is then sterilized, membrane filtered, continuous electric desalination and other steps to obtain terminal water, and collected in the terminal water tank 40, and the reverse osmosis concentrated water obtained after being treated by the reverse osmosis device 30 is directly discharged into the sewer will result in a waste of energy. Such as figure 1 As shown, as an exemplary embodiment of the present invention, a method for recycling concentrated reverse osmosis water is provided, the method comprising: mixing reverse osmosis concentrated water and ultrafiltration water to obtain backwash water, using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com