A chemically modified thermosetting asphalt mixture

A technology of asphalt mixture and chemical modification, which is applied in the field of road engineering asphalt mixture, can solve the problems of difficult pavement quality control, no public reports, irregular cracks, etc., and achieve superior mechanical properties and road performance, and widely Application prospect, excellent effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

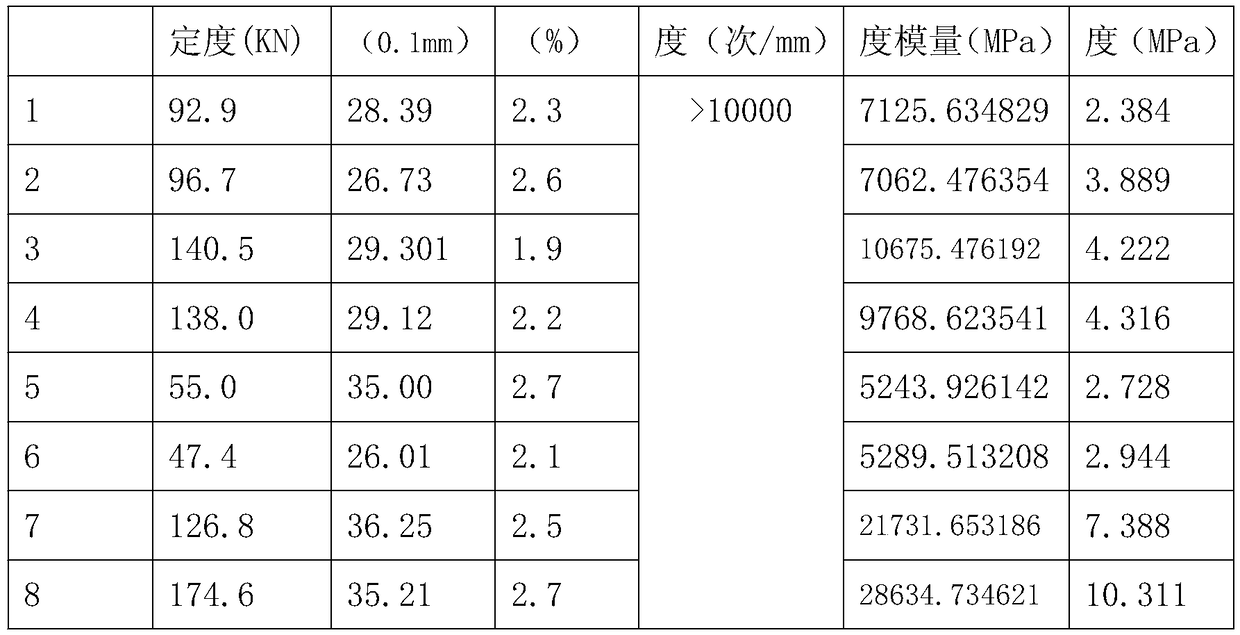

Embodiment 1

[0018] The chemically modified thermosetting asphalt mixture of the present invention is obtained through the following steps:

[0019] (1) Mix the base asphalt, curing agent, auxiliary agent and other modifiers in proportion and then stir for 30 minutes at a temperature of 120°C to obtain the chemically modified thermosetting asphalt B component; the base asphalt is SK70# road With grade A petroleum asphalt, the mass percentage is 79.68%, the curing agent is polysebic anhydride, the mass percentage is 13.94%, the curing accelerator is imidazole, other auxiliary agents are sorbate, curing accelerator and other auxiliary agent quality The percentage is 6.38%;

[0020] (2) Heating bisphenol A type epoxy resin E-51 to 80° C. to obtain component A of epoxy asphalt.

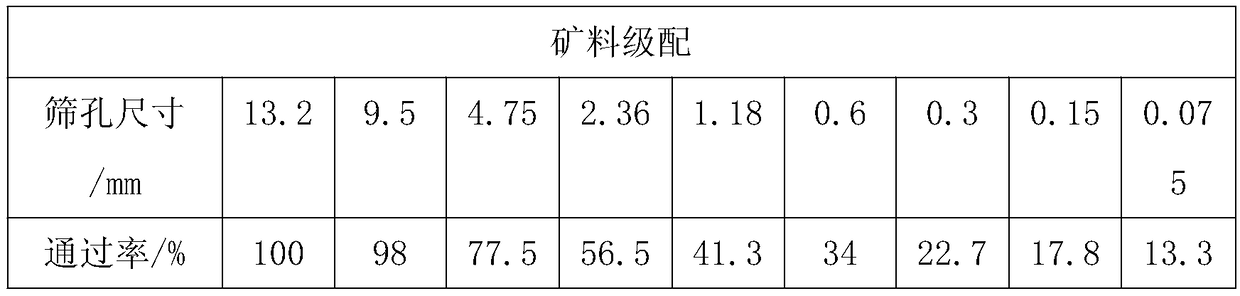

[0021] (3) Grind strong hydrophobic stones from limestone or magmatic rock into mineral aggregates with a particle size below 13mm (see Table 1), weigh 10kg of aggregates of each particle size according to the target...

Embodiment 2

[0024] The chemically modified thermosetting asphalt mixture of the present invention is obtained through the following steps:

[0025] (1) Mix the base asphalt, curing agent, auxiliary agent and other modifiers in proportion and stir for 20 minutes at a temperature of 120°C to obtain the chemically modified thermosetting asphalt B component; the base asphalt is SK70# road With grade A petroleum asphalt, the mass percentage is 79.68%, the curing agent is polysebic anhydride, the mass percentage is 13.94%, the curing accelerator is imidazole, other auxiliary agents are sorbate, curing accelerator and other auxiliary agent quality The percentage is 6.38%;

[0026] (2) Heating bisphenol A type epoxy resin E-51 to 80° C. to obtain component A of epoxy asphalt.

[0027] (3) Grind the strongly hydrophobic stones in limestone or magmatic rock into mineral aggregates with a particle size below 13mm (see Table 1), weigh 10Kg of aggregates of each particle size according to the target ...

Embodiment 3

[0030] The chemically modified thermosetting asphalt mixture of the present invention is obtained through the following steps:

[0031] (1) Mix the base asphalt, curing agent, auxiliary agent and other modifiers in proportion and stir for 20 minutes at a temperature of 130°C to obtain the chemically modified thermosetting asphalt B component; the base asphalt is SK70# road With grade A petroleum asphalt, the mass percent is 73.8%, the curing agent is polysebic anhydride, the mass percent is 19.41%, the curing accelerator is imidazole, other auxiliary agents are sorbate, curing accelerator and other auxiliary agent quality The percentage is 6.79%;

[0032] (2) Heating bisphenol A type epoxy resin E-51 to 80° C. to obtain component A of epoxy asphalt.

[0033] (3) Grind the strongly hydrophobic stones in limestone or magmatic rocks into mineral aggregates with a particle size below 13mm (see Table 1), weigh 10kg of aggregates of each particle size according to the target gradat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com