Adhesive for 3D printing of photocurable ceramic and preparation method and application of adhesive

A 3D printing and 3D printer technology, applied in the direction of additive processing, etc., can solve problems such as incomplete shape and complexity, and achieve the effects of improving productivity, high precision, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

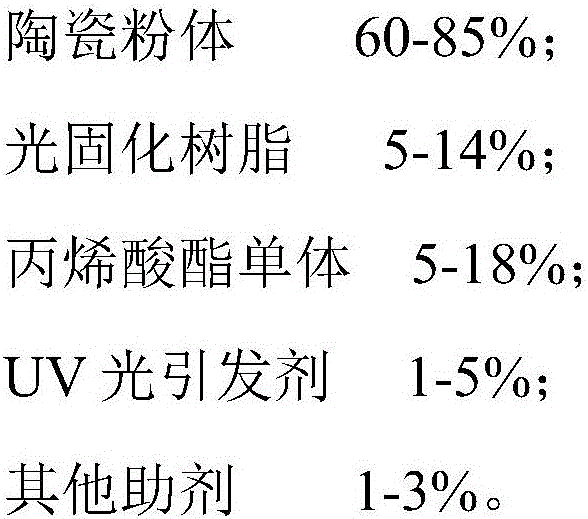

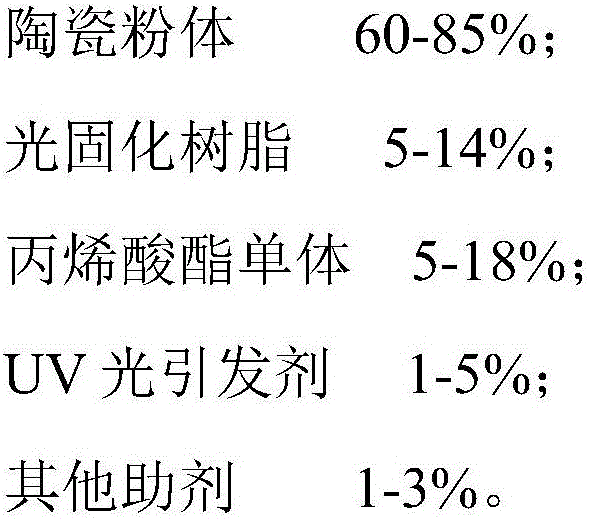

Method used

Image

Examples

preparation example Construction

[0037] Correspondingly, an embodiment of the present invention provides a method for preparing an adhesive for photocuring ceramic 3D printing, comprising the following steps:

[0038] S01. Weigh each component according to the above-mentioned formula of the adhesive used for photocuring ceramic 3D printing;

[0039] S02. Disperse and stir each component while feeding at a constant temperature of 40-50°C, and the stirring speed is 500-600 rpm to obtain a mixed material;

[0040] S03. Cool the mixed material to normal temperature, and perform centrifugal dispersion treatment under vacuum conditions;

[0041] S04. Filtrating the mixed material after centrifugal dispersion to obtain an adhesive slurry.

[0042] Specifically, in the above step S01, the formulation components of the adhesive used for photocuring ceramic 3D printing and its preferred conditions are as described above, and will not be repeated here in order to save space.

[0043] In the above step S02, since the c...

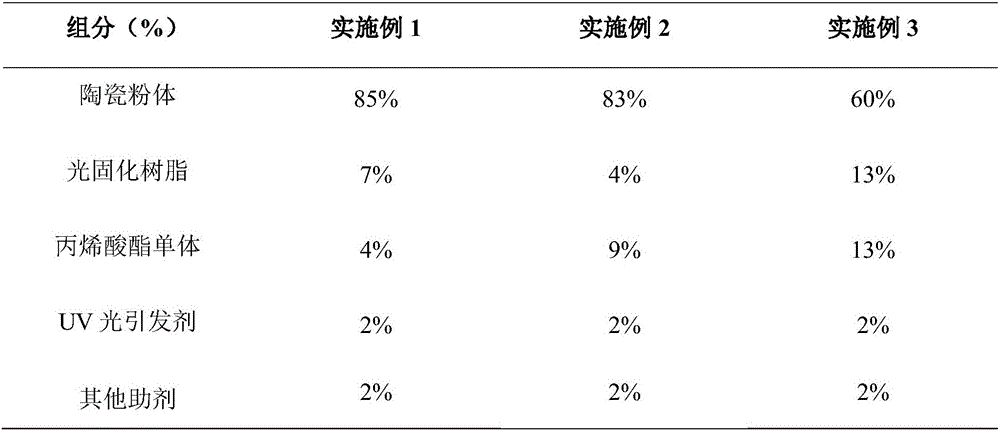

Embodiment 1

[0062] A light-curing 3D printing ceramic, prepared from the adhesive of the formula component in Example 1 of Table 1, wherein the light-curing resin is 3,4-epoxycyclohexyl methacrylate, and the acrylate monomer is 2% of 2-vinyloxyethoxy ethyl methacrylate and 2% of 2-hydroxyethyl acrylate, the ceramic powder is zirconia powder, and the UV photoinitiator is 1% photosensitive initiator Agent 184 and 1% photoinitiator 819, the other additives are wetting agent ammonium polyacrylate.

[0063] The preparation method of the light-cured 3D printing ceramics is as follows:

[0064] Q11. Weigh each component, disperse and stir each component while feeding at a constant temperature of 40-50°C, and the stirring speed is 500-600 rpm to obtain a mixed material; cool the mixed material to room temperature, and Centrifugal dispersion treatment is carried out under the following conditions; the mixed material after centrifugal dispersion is filtered to obtain adhesive slurry

[0065] Q12....

Embodiment 2

[0068] A light-curing 3D printing ceramic, prepared from the adhesive of the formula components in Example 2 of Table 1, wherein the light-curing resin is urethane dimethacrylate, and 6% of the acrylate monomer is cyclic Hexyl-2-(1,3-dioxol-4-yl) acrylate and 3% 2-hydroxyethyl acrylate, the ceramic powder is alumina powder, and the UV photoinitiator is 1% of the photoinitiator 184 and 1% of the photoinitiator ITX, and the other auxiliary agent is ammonium polyacrylate.

[0069] The preparation method of the photocuring 3D printing ceramics is the same as that of Example 1, the depth of UV photocuring is 80 μm, and the sintering temperature is 1250° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com