Method for extracting carthamin yellow from safflowers

A technology of safflower yellow pigment and safflower, which is applied in the direction of chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of long process, high energy consumption, low yield, etc., and reduce production costs and water consumption. consumption and energy consumption, and the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

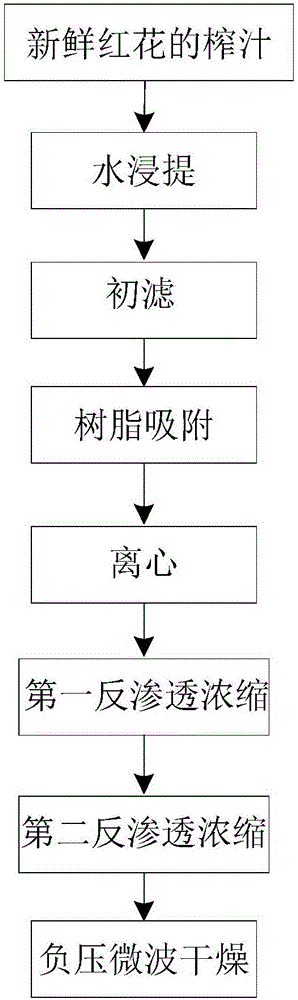

[0044] Such as figure 1Shown, this embodiment provides a kind of method extracting safflower yellow pigment from safflower, specifically:

[0045] Pretreatment of fresh safflower: sorting fresh safflower and carrying out acid treatment to the fresh safflower after sorting, to remove the ash content in the sorted safflower, and acid-treating the fresh safflower Juicing and solid-liquid separation are carried out, wherein, the sorted safflower is added to 0.2% hydrochloric acid and soaked for 10 minutes, and after washing with water, the residual acid content is not more than 0.4g / L;

[0046] Water leaching: extract the residue obtained from solid-liquid separation to obtain an extract; wherein, the solid-to-liquid ratio of the residue to deionized water is 1:10, the soaking time is 1.8 hours, and the extraction temperature is 40°C. The extraction time is 2.5 hours, and the number of extractions is 2 times: put the residue into the extraction tank, add deionized water of the fi...

Embodiment 2

[0053] Such as figure 1 Shown, this embodiment provides a kind of method extracting safflower yellow pigment from safflower, specifically:

[0054] The pretreatment of fresh safflower: sorting fresh safflower, carrying out acid treatment to the fresh safflower after sorting, and squeezing the fresh safflower after acid treatment and separating solid and liquid, wherein, the sorted fresh safflower The safflower is soaked in 0.2% sulfuric acid for 10 minutes, and washed with water until the residual acid content is not more than 0.4g / L;

[0055] Water leaching: the residue obtained from solid-liquid separation is subjected to water leaching to obtain an extract; wherein, the solid-liquid ratio of the residue to deionized water is 1:11, the immersion time is 2.2 hours, and the leaching temperature is 30°C. The extraction time is 3.5 hours, and the number of extractions is 2 times. Put the residue into the extraction tank, add the first quality deionized water for the first extra...

Embodiment 3

[0062] Such as figure 1 Shown, this embodiment provides a kind of method extracting safflower yellow pigment from safflower, specifically:

[0063] The pretreatment of fresh safflower: sorting fresh safflower, carrying out acid treatment to the fresh safflower after sorting, and squeezing the fresh safflower after acid treatment and separating solid and liquid, wherein, the sorted fresh safflower The safflower is soaked in 0.2% sulfuric acid for 10 minutes, and washed with water until the residual acid content is not more than 0.4g / L;

[0064] Water leaching: extract the residue obtained from solid-liquid separation to obtain an extract; wherein, the solid-to-liquid ratio of the residue to deionized water is 1:11, the immersion time is 2.0 hours, the leaching temperature is 35°C, and the leaching The extraction time is 3.0 hours, and the number of extractions is 2 times: put the residue into the extraction tank, add the first quality deionized water for the first extraction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com