Gradient hardness heat treatment method for hob cutter ring of full-face tunnel boring machine

A technology of tunnel boring machine and heat treatment method, applied in the field of vacuum heat treatment, can solve the problems of unsuitability for mass production, unstable quality, low production efficiency, etc., and achieve the effects of being beneficial to installation and coordination, reducing the overall fracture tendency and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

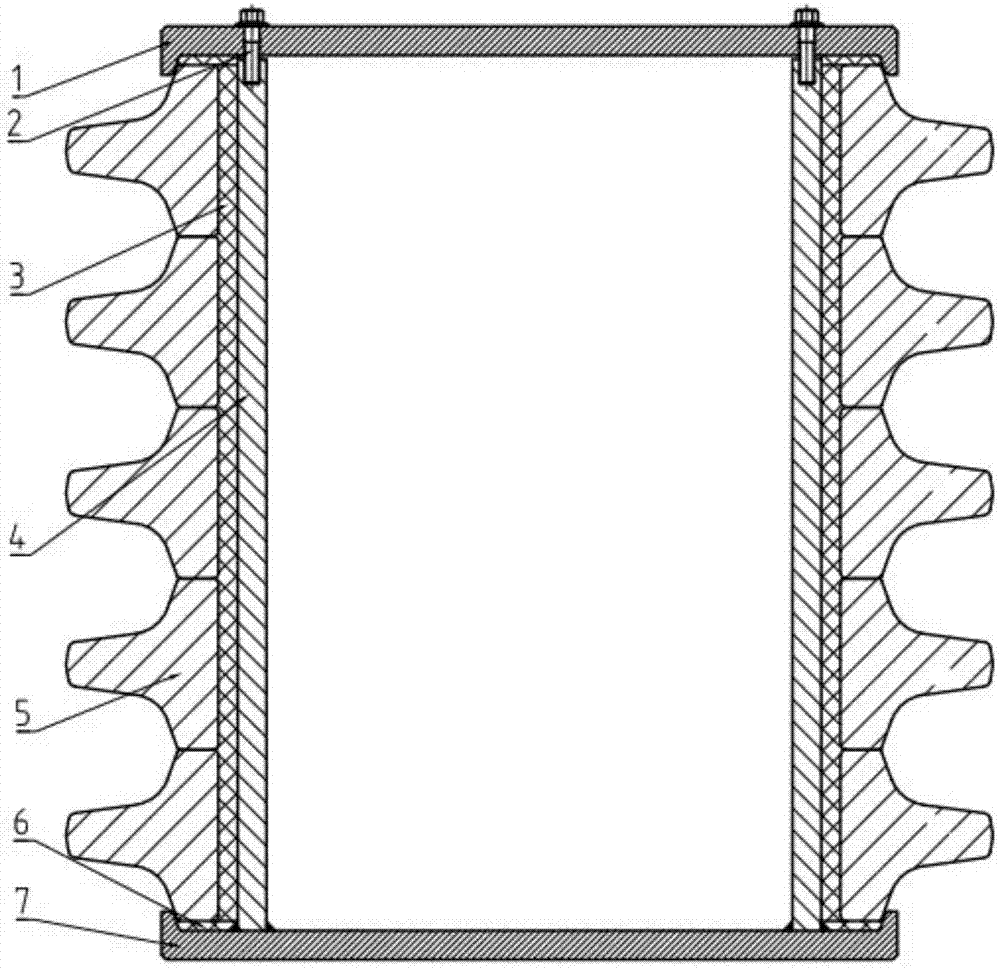

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

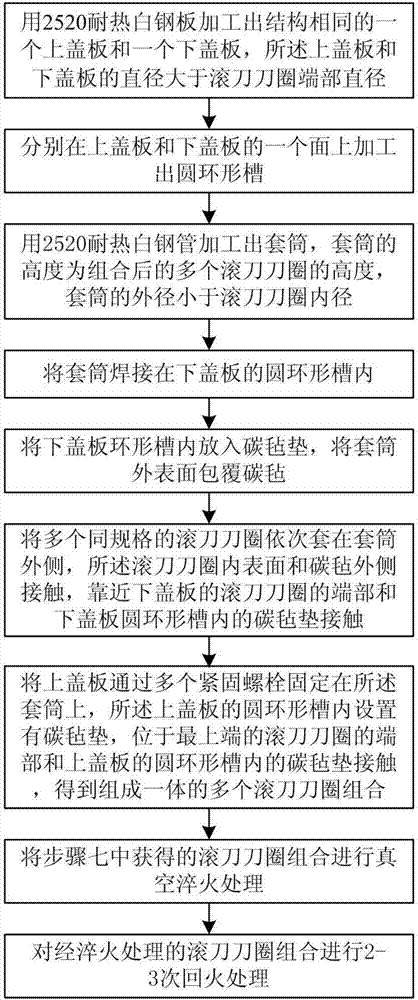

[0037] See attached figure 1 And attached figure 2 , the gradient hardness heat treatment method of the full-face tunnel boring machine hob cutter ring of the present invention comprises the following steps:

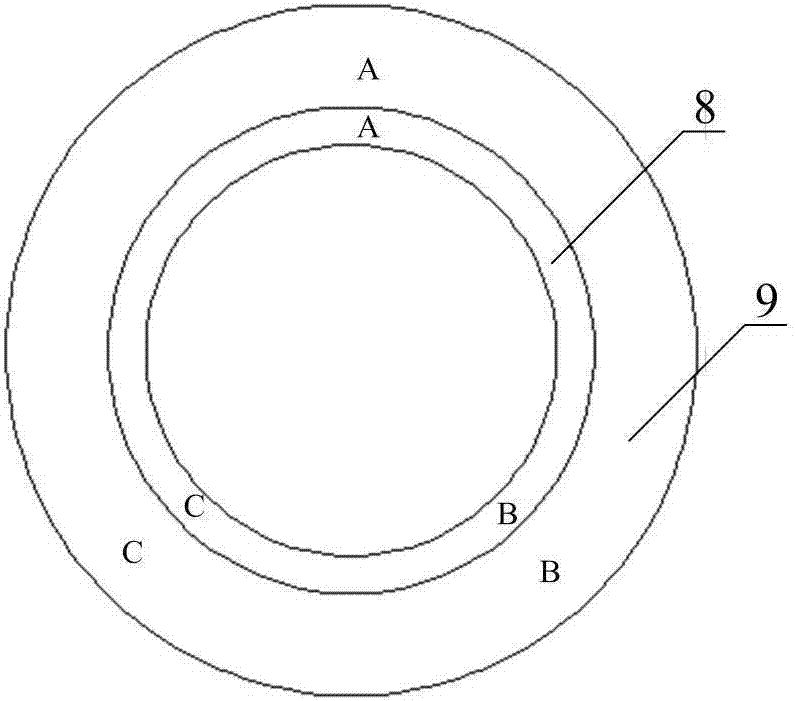

[0038] Step 1: using 2520 heat-resistant white steel plate to process an upper cover plate 1 and a lower cover plate 7 with the same structure, the diameters of the upper cover plate 1 and the lower cover plate 7 are larger than the diameter of the end 8 of the hob cutter ring 5;

[0039] Step 2: Process a circular groove on one surface of the upper cover plate 1 and the lower cover plate 7 respectively;

[0040] Step 3: Process a sleeve 4 with 2520 heat-resistant white steel pipe, the height of the sleeve 4 is the height of the combined multiple hob cutter rings 5, and the outer diameter of the sleeve 4 is smaller than the hob cutter ring 5 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com