Frog hammer device with solar panel and working method thereof

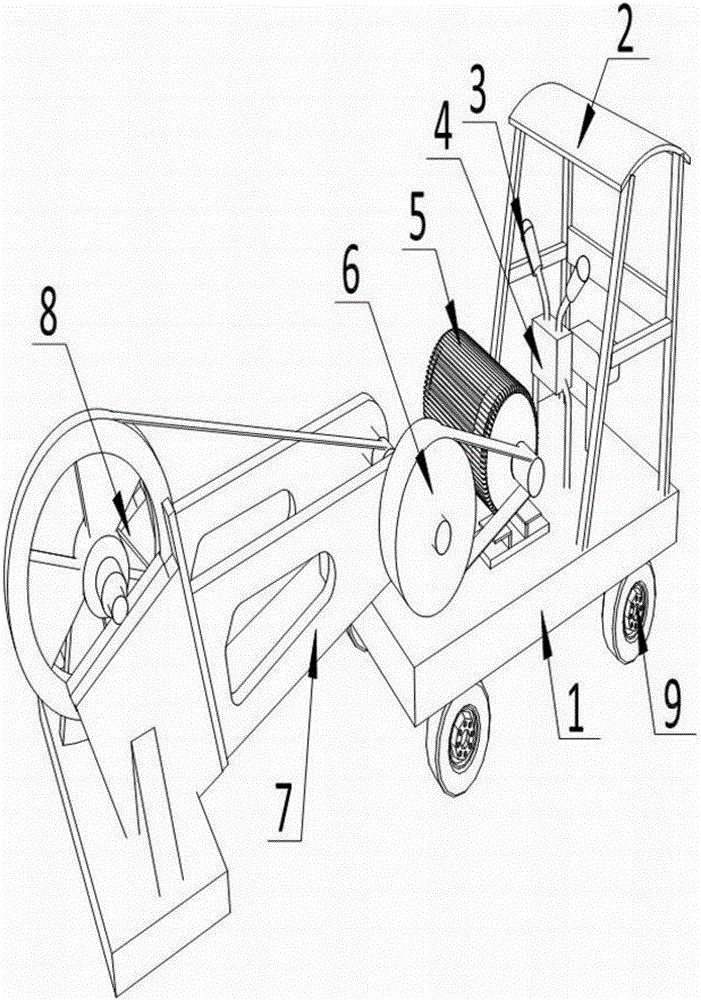

A solar panel and tamping machine technology, which is applied to circuit devices, battery circuit devices, soil protection, etc., can solve problems such as the use of large forces, hidden safety hazards, and limited operating range, and achieve high tamping flatness, The effect of wide construction range and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

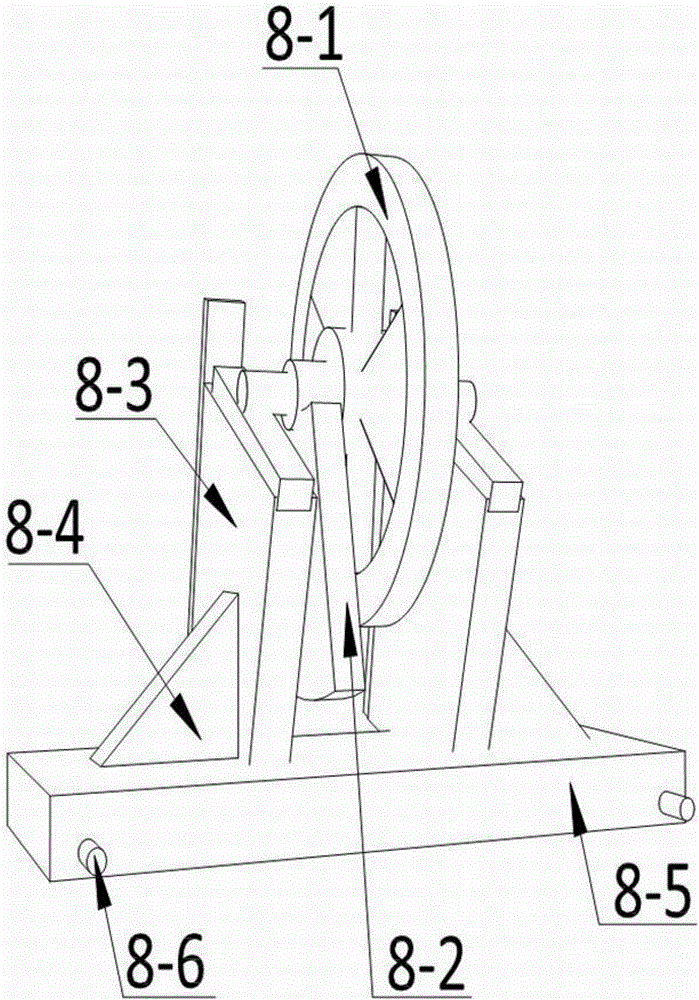

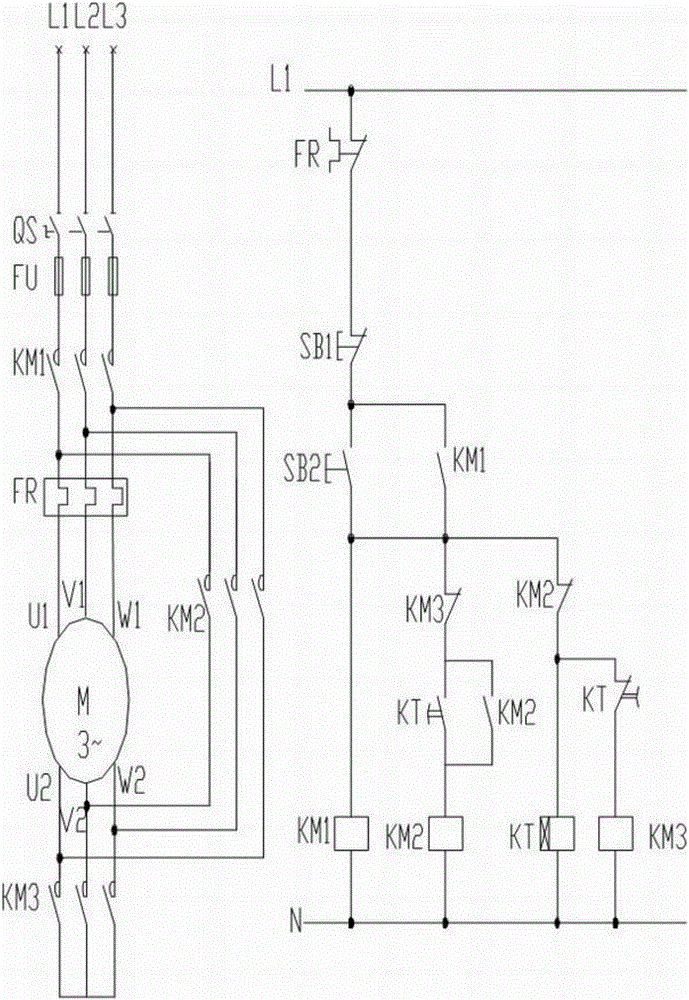

Method used

Image

Examples

Embodiment 1

[0045] Manufacture the solar concentrating panel 2 of the present invention according to the following steps, and in parts by weight:

[0046] Step 1: Add 2280 parts of ultrapure water with a conductivity of 5.66μS / cm into the reactor, start the agitator in the reactor at a speed of 93rpm, start the heating pump, and raise the temperature in the reactor to 39°C; add in sequence 18 parts of 1-[2-[(4-chlorophenyl)methoxy]-2-(2,4-dichlorophenyl)ethyl]-1H-imidazole, (R,S)-3-propenyl -2-Methyl-4-oxocyclopent-2-enyl (1R) cis, trans-2,2-dimethyl-3-(2-methyl-1-propenyl) cyclopropanecarboxylate 71 parts, (R)-N-(3-fluoro-4-morpholine phenyl)-oxazolone-5-methyl alcohol 59 parts, stir until completely dissolved, adjust the pH value to 4.3, adjust the speed of the agitator to 122rpm, the temperature is 82°C, and the esterification reaction is 16 hours;

[0047] Step 2: Take D-trans-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-(R,S)-2methyl-3-(2 36 parts of -propargyl)...

Embodiment 2

[0052] Manufacture the solar concentrating panel 2 of the present invention according to the following steps, and in parts by weight:

[0053] Step 1: Add 2760 parts of ultrapure water with a conductivity of 10.34μS / cm into the reactor, start the stirrer in the reactor at a speed of 155rpm, and start the heating pump to raise the temperature in the reactor to 81°C; add in sequence 66 parts of 1-[2-[(4-chlorophenyl)methoxy]-2-(2,4-dichlorophenyl)ethyl]-1H-imidazole, (R,S)-3-propenyl -2-Methyl-4-oxocyclopent-2-enyl (1R) cis, trans-2,2-dimethyl-3-(2-methyl-1-propenyl) cyclopropanecarboxylate 153 parts, (R)-N-(3-fluoro-4-morpholine phenyl)-oxazolone-5-methyl alcohol 104 parts, stir until completely dissolved, adjust the pH value to 7.5, adjust the speed of the agitator To 184rpm, the temperature is 137°C, and the esterification reaction is 25 hours;

[0054]Step 2: Take D-trans-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-(R,S)-2methyl-3-(2 -propargyl)-4-oxo-...

Embodiment 3

[0058] Manufacture the solar concentrating panel 2 of the present invention according to the following steps, and in parts by weight:

[0059] Step 1: Add 2430 parts of ultrapure water with a conductivity of 8.33μS / cm into the reactor, start the stirrer in the reactor at a speed of 125rpm, start the heating pump, and raise the temperature in the reactor to 54°C; 33 parts of 1-[2-[(4-chlorophenyl)methoxy]-2-(2,4-dichlorophenyl)ethyl]-1H-imidazole, (R,S)-3-propenyl -2-Methyl-4-oxocyclopent-2-enyl (1R) cis, trans-2,2-dimethyl-3-(2-methyl-1-propenyl) cyclopropanecarboxylate 111 parts, 84 parts of (R)-N-(3-fluoro-4-morpholine phenyl)-oxazolone-5-methyl alcohol, stir until completely dissolved, adjust the pH value to 5.6, adjust the speed of the agitator To 152rpm, the temperature is 107°C, and the esterification reaction is 20 hours;

[0060] Step 2: Take D-trans-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-(R,S)-2methyl-3-(2 59 parts of -propargyl)-4-oxo-cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com