Light steel keel composite concrete wallboard hoisting structure and mounting method thereof

A light steel keel and concrete technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex manufacturing process, inconvenient lifting, inconvenient installation, lack of lifting and installation structure, etc., to improve the construction speed and construction period. The effect of shortening and quick wall installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings.

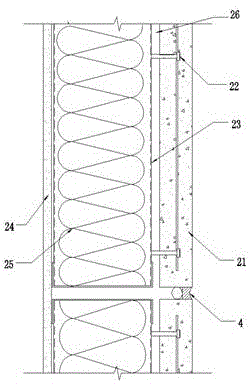

[0058] Such as figure 1 As shown, a light steel keel composite concrete wall panel hoisting structure is composed of a light steel keel frame 23, a concrete slab 21 and a keel concrete slab connector 22, and the light steel keel frame 23 strengthens the bending and shear strength of the concrete slab The concrete slab 21 acts as a skin effect, and the two are organically combined through the connector 22 to form a composite wall with excellent bending resistance. The inside of the light steel keel frame 23 can be filled with thermal insulation material 25, and boards such as cement fiberboard or gypsum board can be installed in the inside as the wall inner surface 24.

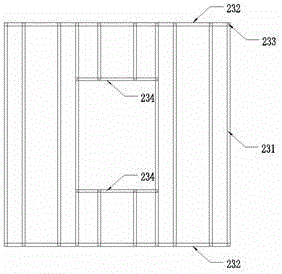

[0059] Such as figure 1 , figure 2 As shown, the light steel keel frame 23 is composed of a heaven and earth keel 232 and a vertical keel 231, the sky and earth keel 232 adopts a U-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com