Novel vacuum compression system

A new type of vacuum compression technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, pump devices, etc. It can solve the problem of reduced flow rate, inability to meet the requirements of large volume, and inability to increase without limit Problems such as pump volume specifications, etc., to achieve the effect of increasing the pumping capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

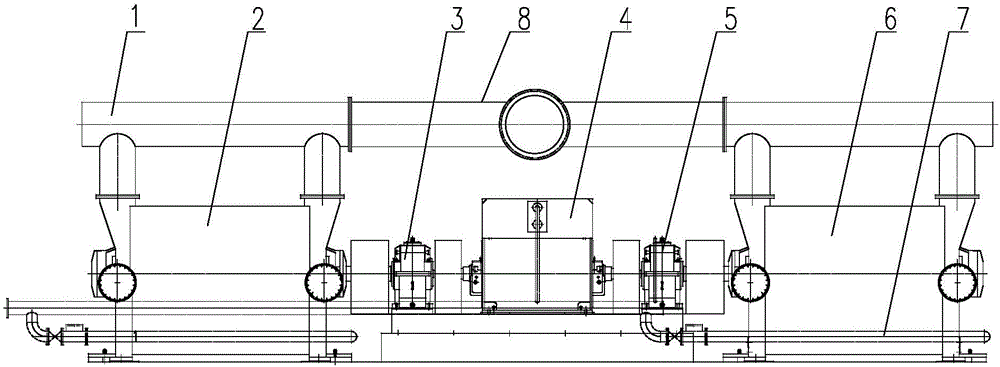

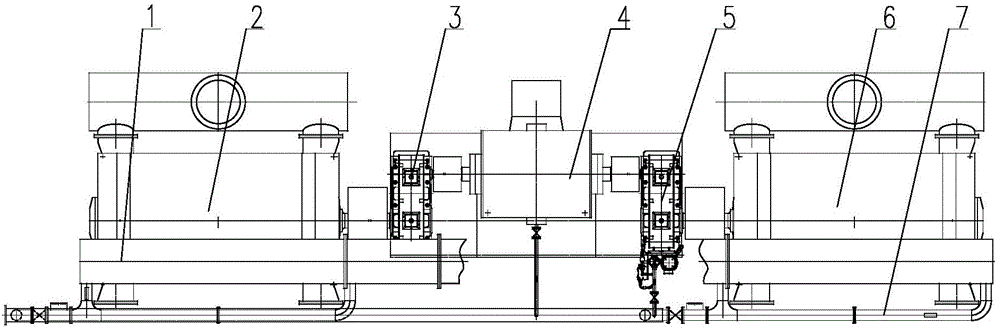

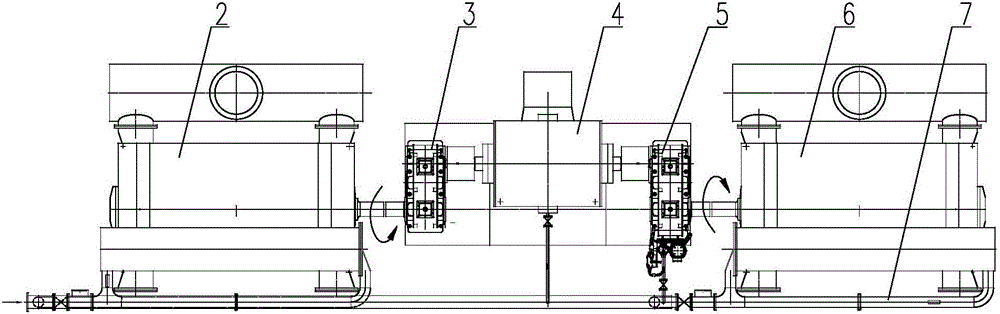

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as Figure 1 to Figure 5 As shown, the novel vacuum compression system of the present invention includes a motor 4, the motor 4 is a double-shaft motor 4, and the two output ends are respectively connected to the vacuum pump A2 through the reducer A3, connected to the vacuum pump B6 through the reducer B5, the vacuum pump A2 and the vacuum pump B6 are double-suction vacuum pumps, the air inlets of vacuum pump A2 and vacuum pump B6 are respectively connected to the air inlet pipe 1, and the two air inlet pipes 1 are connected to the general air inlet of the vacuum system through the air inlet tee 8, and the exhaust ports of vacuum pump A2 and vacuum pump B6 connected to the exhaust pipe respectively. Both the vacuum pump A2 and the vacuum pump B6 are connected to the sealed cooling system 7, and the sealed cooling system 7 includes a cooling main pipe, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com