Pneumatic gear shifting system of automotive mechanical gearbox

A mechanical transmission and pneumatic shifting technology, applied in the field of auto parts, can solve the problems of not being able to meet the power requirements of taxis and buses, small transmission torque of CVT automatic transmission, complex working condition signal collection and calculation, etc., to achieve The structure is simple, the smoothness of shifting is improved, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

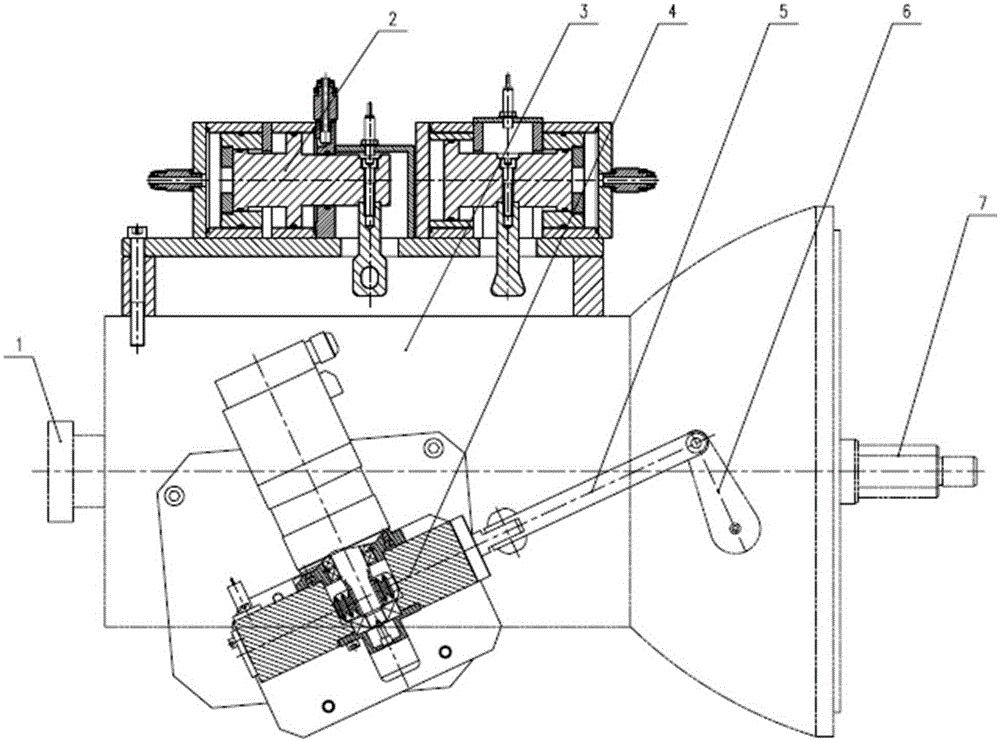

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the six accompanying drawings.

[0033] The power transmission structure in the technical solution of the present invention is the same as the power transmission structure of the manual gearbox, that is, the power transmission is transmitted from the engine to the transmission and then to the output component to realize power transmission.

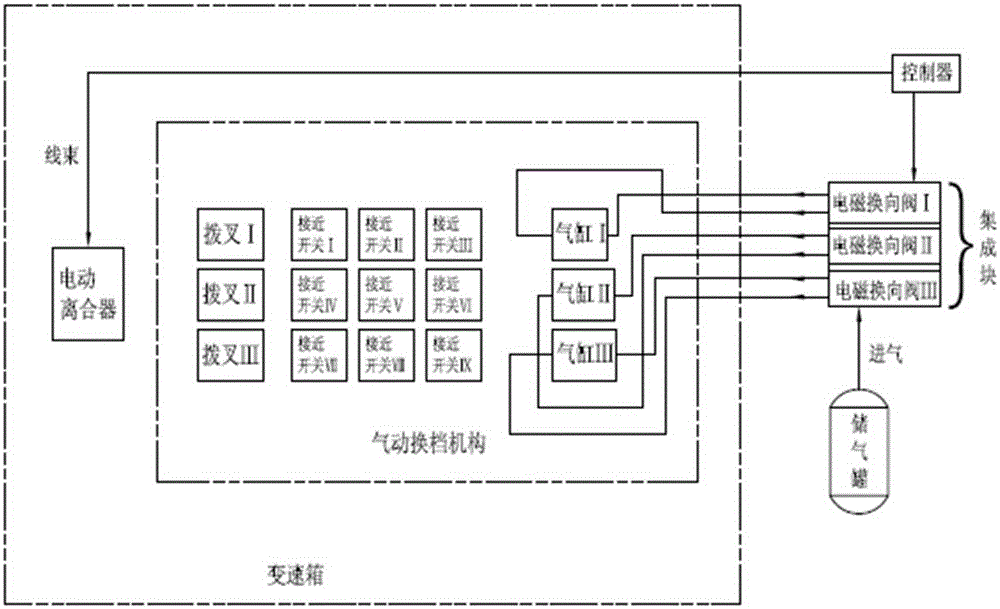

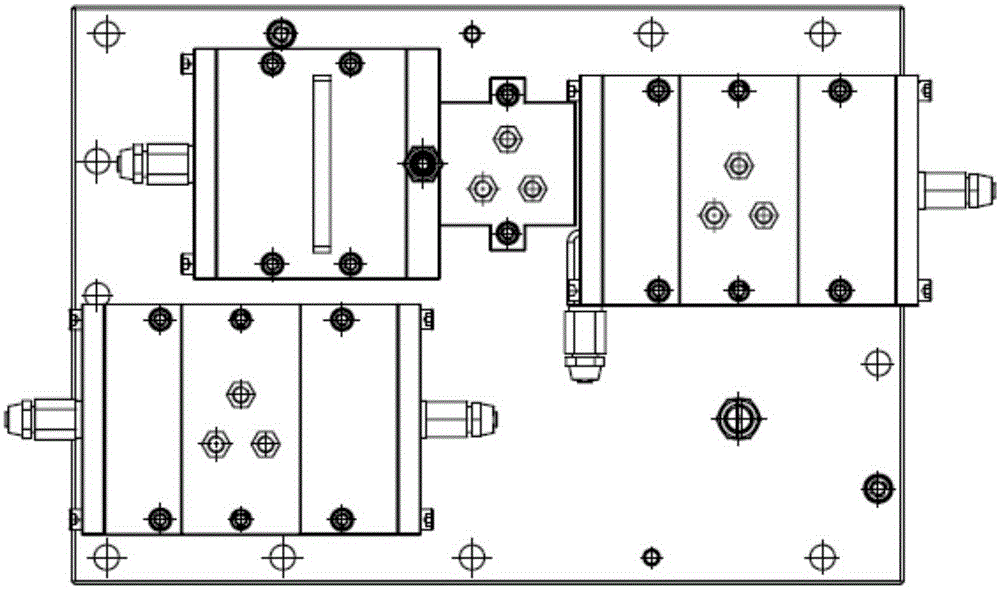

[0034] Such as figure 1As shown, the schematic diagram of pneumatic shift mechanism and electric clutch system control, the controller directly controls the action of the electric clutch, and the electric clutch also feeds back the clutch signal to the controller; electromagnetic reversing valve I, electromagnetic reversing valve II, electromagnetic reversing valve Ⅲ constitutes the integrated block of electromagnetic reversing valve. The controller directly controls the electromagnetic reversing valve. The cylinder of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com