Air ventilation model for hydraulic test

A technology of model and introduction tube, which is applied in fluid dynamics test, machine/structural component test, measuring device, etc., can solve problems such as unsatisfactory test requirements, expand the space for internal pressure stabilization, and satisfy large ventilation volume The effect of demand, length shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

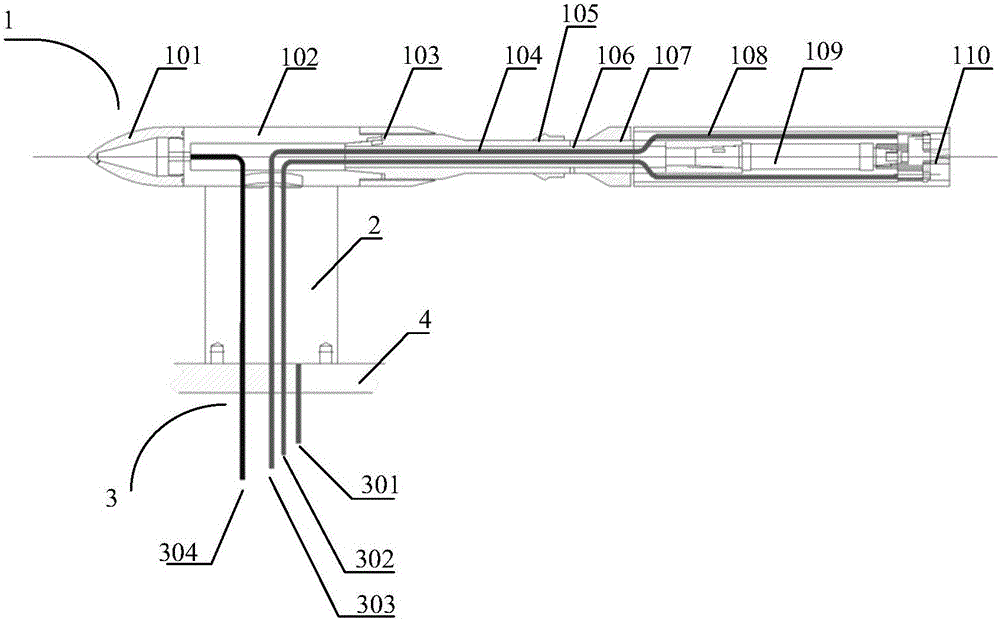

[0027] The underwater test ventilation model of the present invention is a similar scale model after the vehicle body is scaled down, and is used for the water tunnel test of the vehicle body, and mainly includes a main body 1 , a supporting airfoil 2 and a pipeline 3 .

[0028] (1) Main part

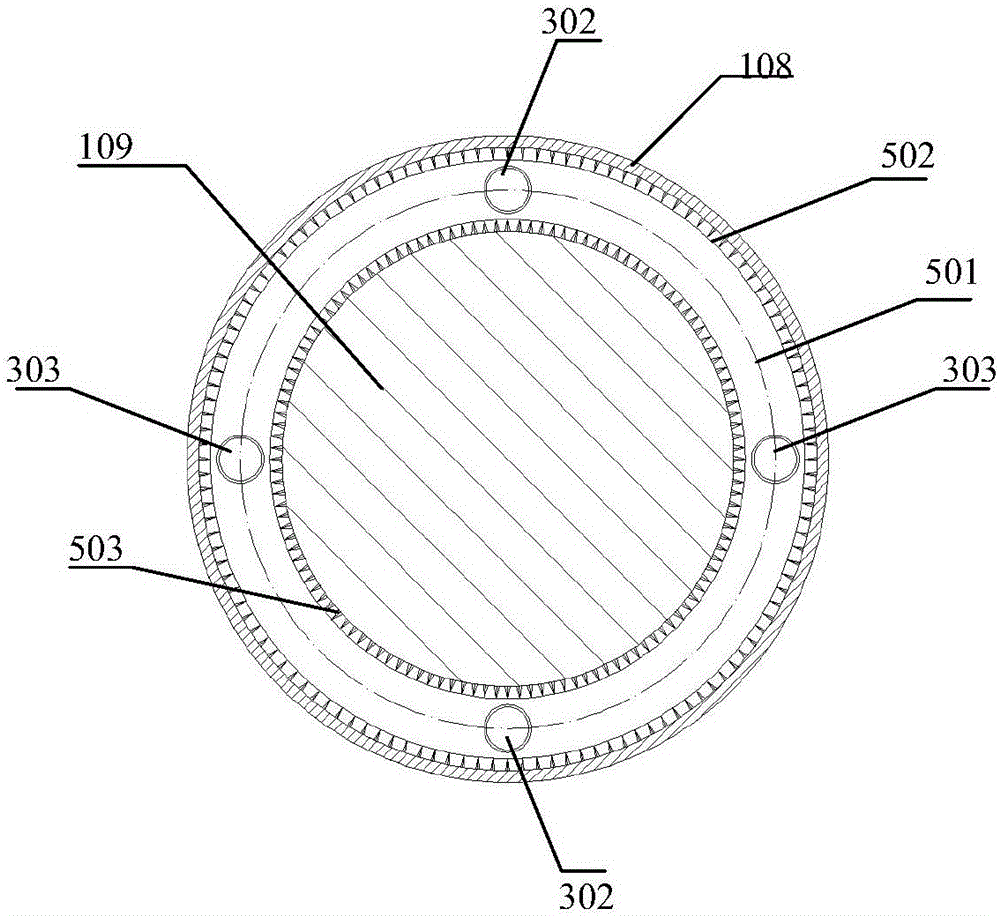

[0029] Such as figure 1 As shown in the vertical axis sectional view, the main part 1 of the water test ventilation model provided by the present invention consists of a head 101, a front section 102, a connecting sleeve 103, a tail support sleeve 104, a cavitator 105, a vent hole 106, and a cone after deflation. Pipe 107, rear section outer casing 108, six-component balance 109, nozzle 110 constitute.

[0030] Wherein, the head 101 is connected to the front section 102, and the other end of the front section 102 is connected to the supporting tail sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com